Double Nut Cooled Ball Screw

A ball screw, cooling technology, applied in the direction of gear lubrication/cooling, transmission, belt/chain/gear, etc., can solve problems such as improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

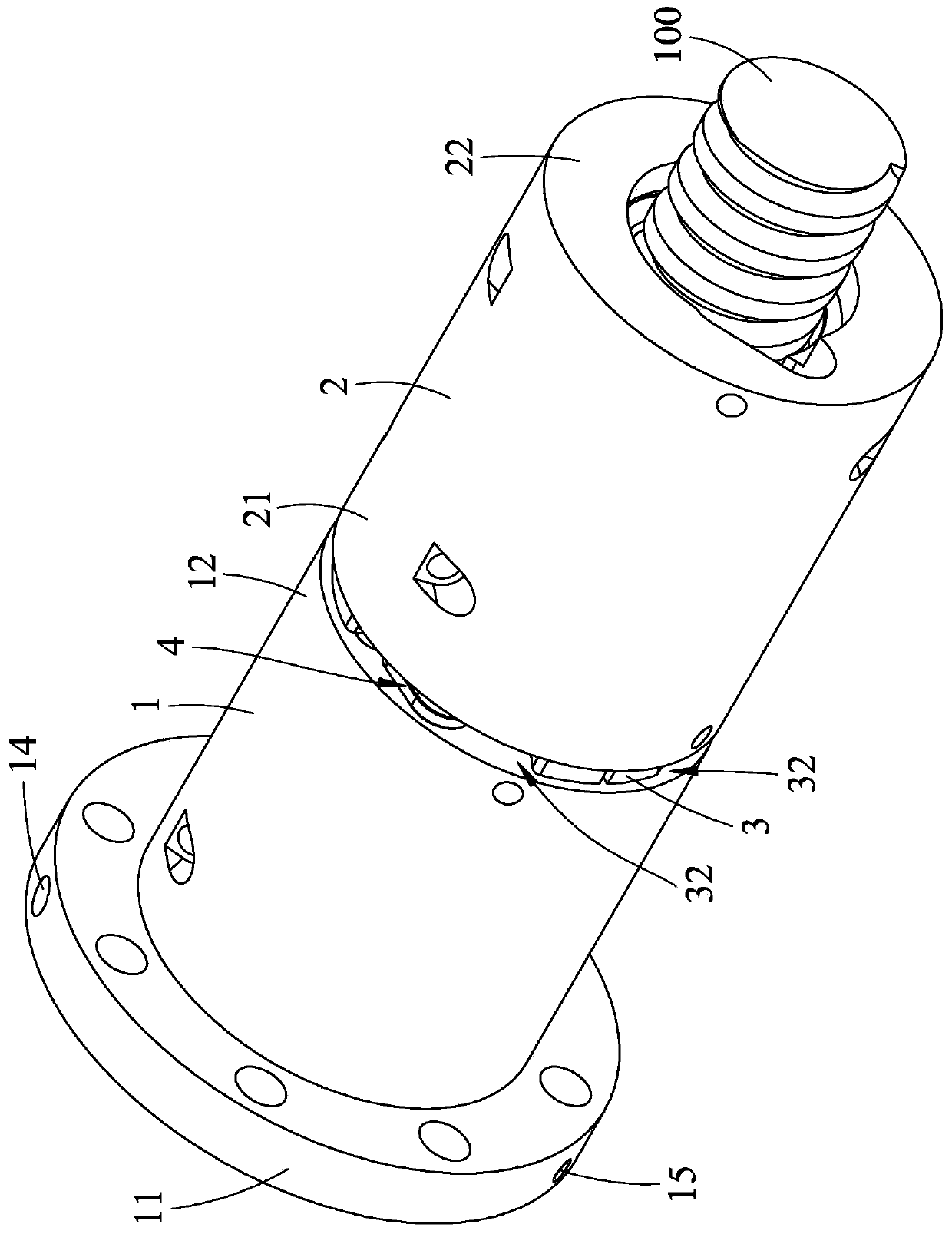

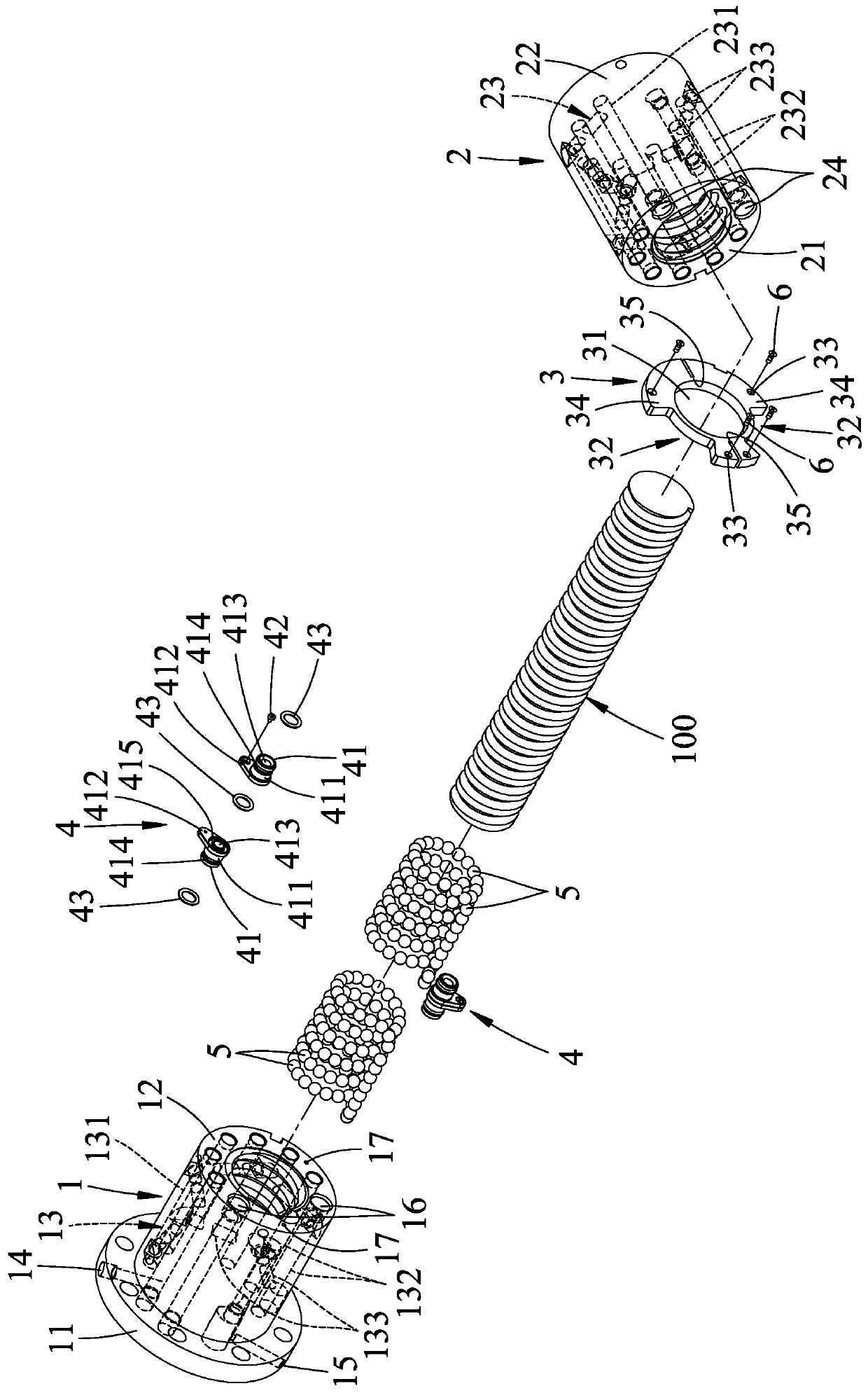

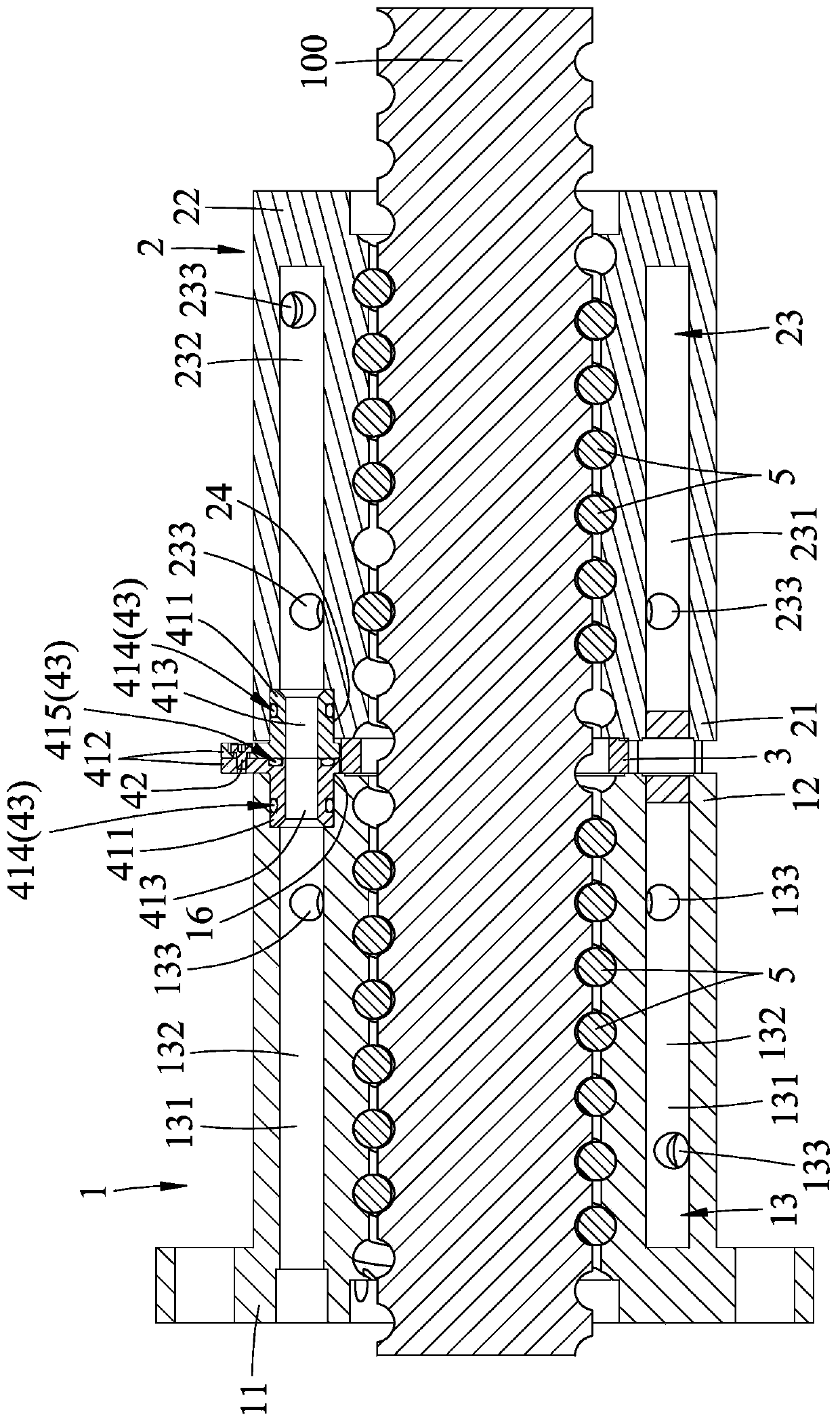

[0032] refer to figure 1 , figure 2 and image 3 , an embodiment of the double-nut cooling ball screw of the present invention includes a screw 100 , a first nut 1 , a second nut 2 , a spacer 3 , and a plurality of guide groups 4 .

[0033] The first nut 1 is screwed on the screw 100 through a plurality of balls 5, and includes a head end 11, a first connecting end 12 opposite to the head end 11, a first connecting end 12 formed inside and having two The first cooling passage group 13 of the first cooling passage 131 spaced apart, one input port 14 formed on the head end 11, one output port 15 formed on the head end 11, two spaced around the screw 100 An connecting hole 16 is formed on the end surface of the first connecting end portion 12 , and four pin holes 17 are formed on the end surface of the first connecting end portion 12 at intervals aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com