Mg-TM super-multilayer composite hydrogen storage film and preparation method thereof

A composite film and super multi-layer technology, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problem of slow hydrogen absorption/desorption rate of hydrogen storage composite film and complex preparation process of hydrogen storage composite film , high dehydrogenation temperature and other problems, achieve fast absorption/dehydrogenation rate, lower dehydrogenation temperature, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of Mg-Ni super multilayer composite hydrogen storage film specifically comprises the following steps:

[0042] (1) Clean the substrate with deionized water first, and then clean it with absolute ethanol. After cleaning, put it in a domestic DHG-9055A blast drying oven to dry; after the substrate pretreatment is completed, fix the substrate on On the substrate of the domestic JGP560-B6 ultra-high vacuum magnetron sputtering system, adjust the distance between the substrate and the center of the substrate so that the substrate can be aligned with the Mg and Ni targets respectively;

[0043] (2) Use the domestic RVP-4 rotary vane vacuum pump to pump the vacuum degree of the sputtering chamber of the ultra-high vacuum magnetron sputtering system to 8.0×10 -4 Pa, the argon gas with a purity of 99.99% is introduced and the sputtering working pressure of 0.8 Pa is achieved with the flow controller;

[0044] (3) Start sputtering after the sputtering working pre...

Embodiment 2

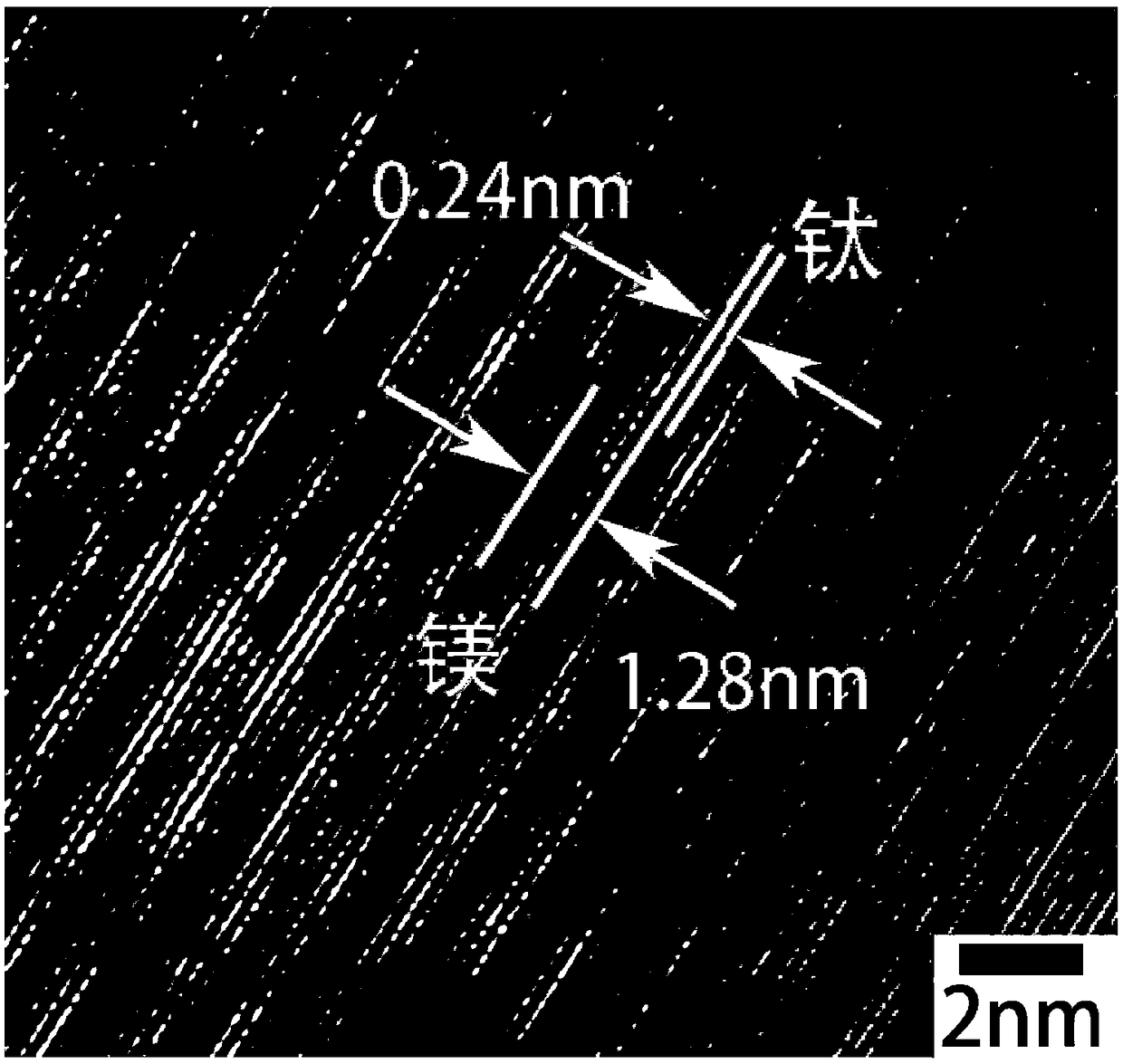

[0049] The preparation of the Mg-Ti super multilayer composite hydrogen storage film specifically includes the following steps:

[0050] (1) Clean the substrate with deionized water first, and then clean it with absolute ethanol. After cleaning, put it in a domestic DHG-9055A blast drying oven to dry; after the substrate pretreatment is completed, fix the substrate on On the substrate of the domestic JGP560-B6 ultra-high vacuum magnetron sputtering system, adjust the distance between the substrate and the center of the substrate so that the substrate can be aligned with the Mg and Ti targets respectively;

[0051] (2) Use the domestic FD-IIB molecular pump to pump the vacuum degree of the sputtering chamber of the ultra-high vacuum magnetron sputtering system to 8.0×10 -4 Pa, the argon gas with a purity of 99.99% is introduced and the sputtering working pressure is reached to 0.8Pa with the flow controller;

[0052] (3) Start sputtering after the working pressure of sputterin...

Embodiment 3

[0058] The preparation of the Mg-Ti super multilayer composite hydrogen storage film specifically includes the following steps:

[0059] (1) Clean the substrate with deionized water first, and then clean it with absolute ethanol. After cleaning, put it in a domestic DHG-9055A blast drying oven to dry; after the substrate pretreatment is completed, fix the substrate on On the substrate of the domestic JGP560-B6 ultra-high vacuum magnetron sputtering system, adjust the distance between the substrate and the center of the substrate so that the substrate can be aligned with the Mg and Ti targets respectively;

[0060] (2) Use the domestic RVP-4 rotary vane vacuum pump to pump the vacuum degree of the sputtering chamber of the ultra-high vacuum magnetron sputtering system to 8.0×10 -4 Pa, the argon gas with a purity of 99.99% is introduced and the sputtering working pressure is reached to 0.8Pa with the flow controller;

[0061] (3) Start sputtering after the working pressure of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com