Electric connector with self-adaptive rotating position for transmitting torque

A technology of rotating position and transmitting torque, which is applied in the direction of connection, two-part connecting device, circuit, etc., can solve the problems of inability to realize axial displacement and torque transmission, and achieve easy mass promotion, stable and reliable torque transmission, and load protection The effect of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

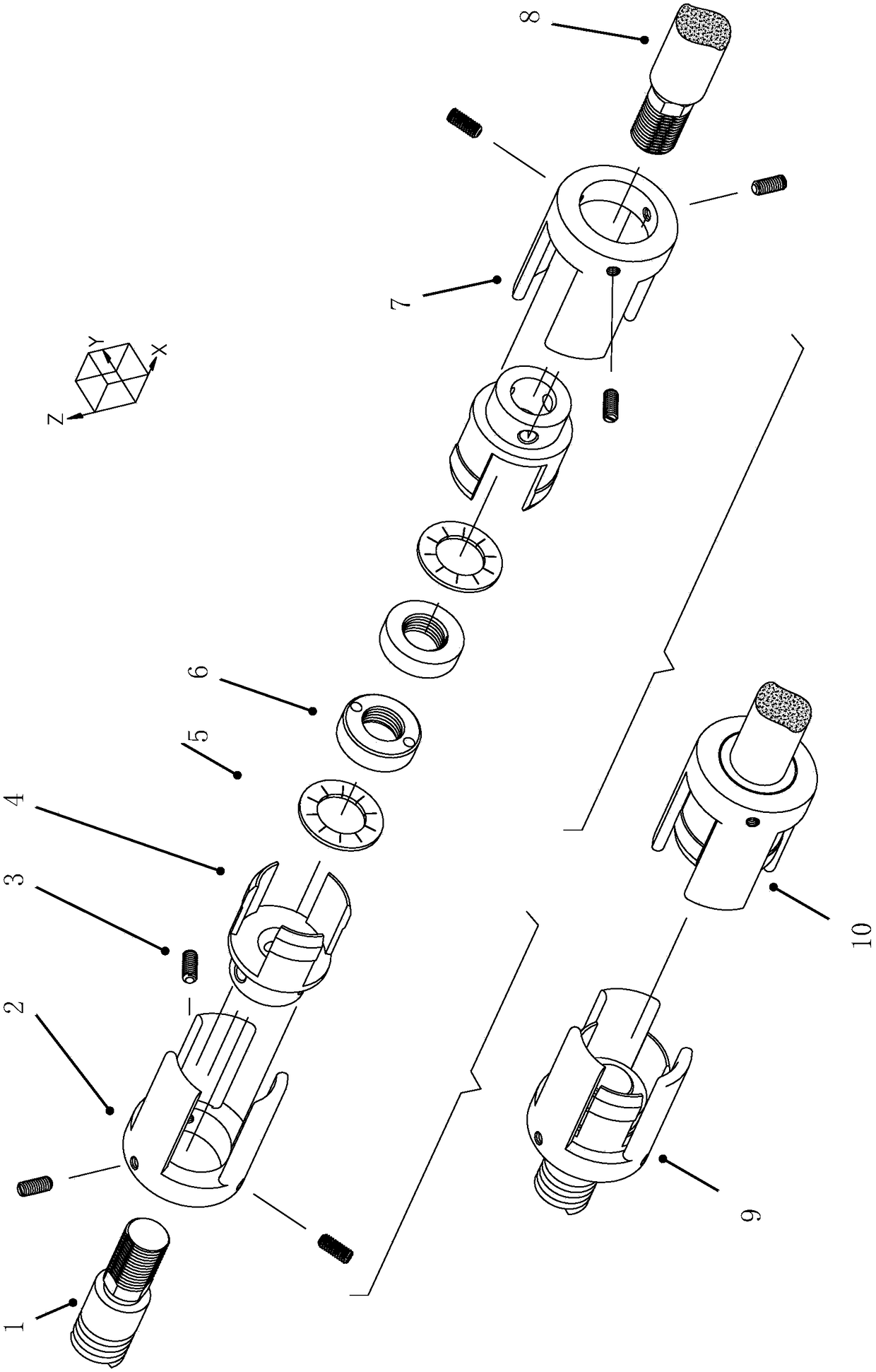

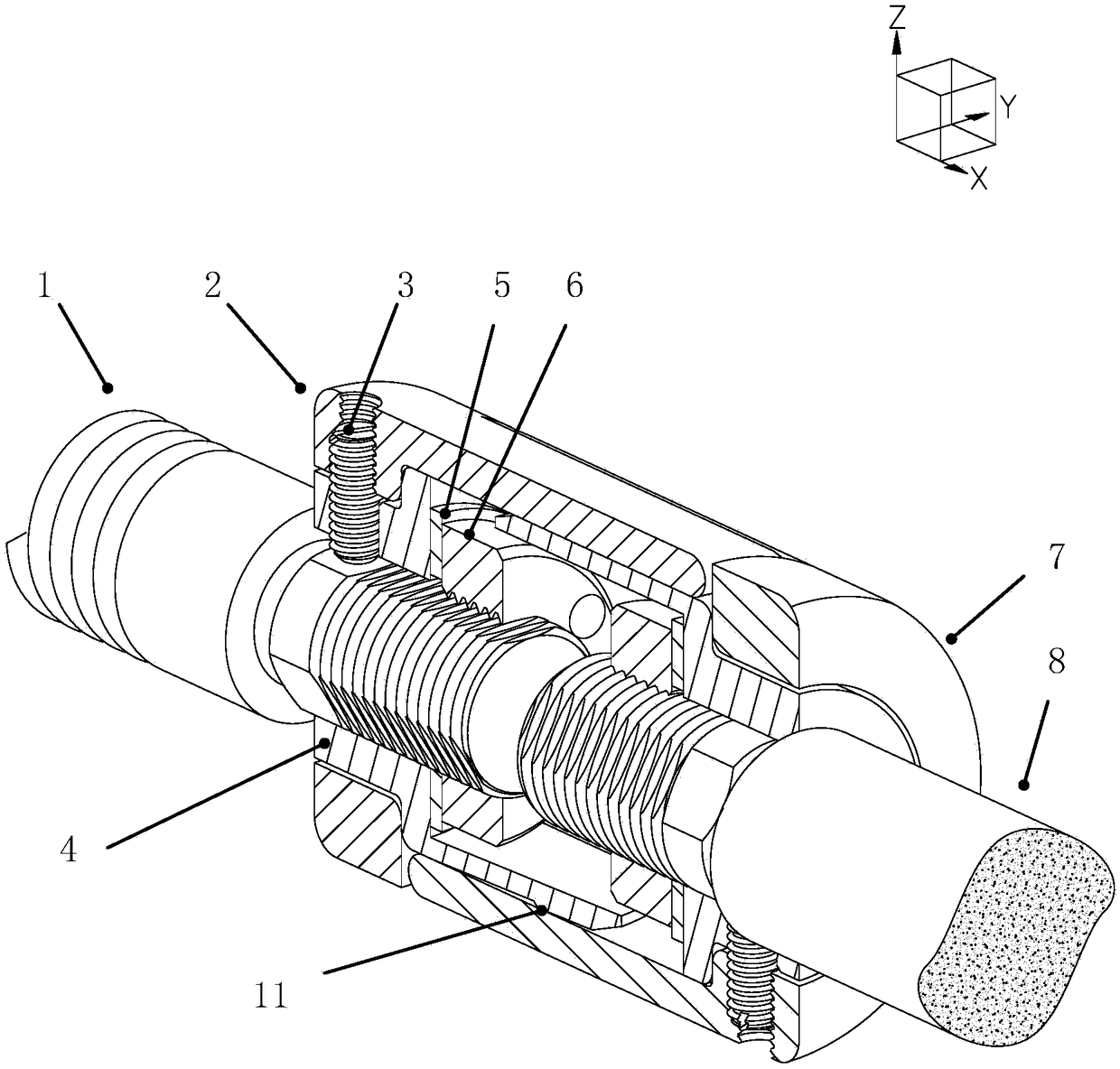

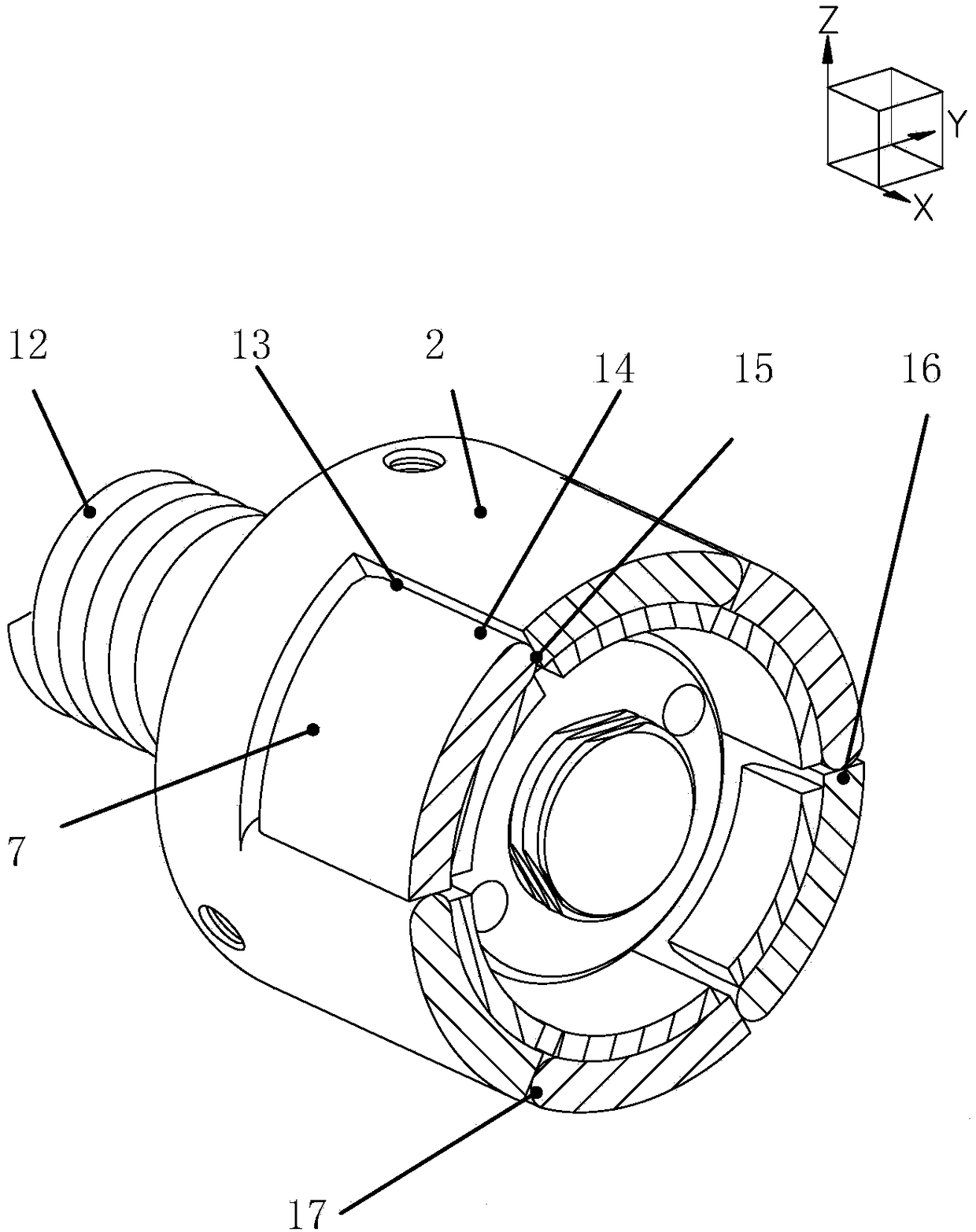

[0021] An electrical connector for torque transmission with adaptive rotational position, including an input element 9 and an output element 10, an array of elastic pins and socket elements at intervals of 120° in the circumferential direction of the element, forming six radial elastic pin-hole engagement structures, At the same time, the cylindrical surface of the side wall of the socket mirror part and the plane of the side wall of the socket part form one-way three motion pairs, and the cylindrical surface of the side wall of the socket part and the side wall plane of the mirror part of the socket form three motion pairs in the opposite direction. A total of 6 motion pairs in both directions to reverse the load. In addition, a threaded segment is provided at one end of the output shaft to achieve an axial displacement that can be accurately measured.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com