Bolt type hub brake disc assembly with heat dissipation for commercial vehicle

A technology for brake discs and commercial vehicles, applied in the direction of brake discs, brakes, brake components, etc., can solve the problems of affecting driving safety, low heat dissipation efficiency, affecting the braking effect of brake discs, etc., to improve the force Working conditions, long service life, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

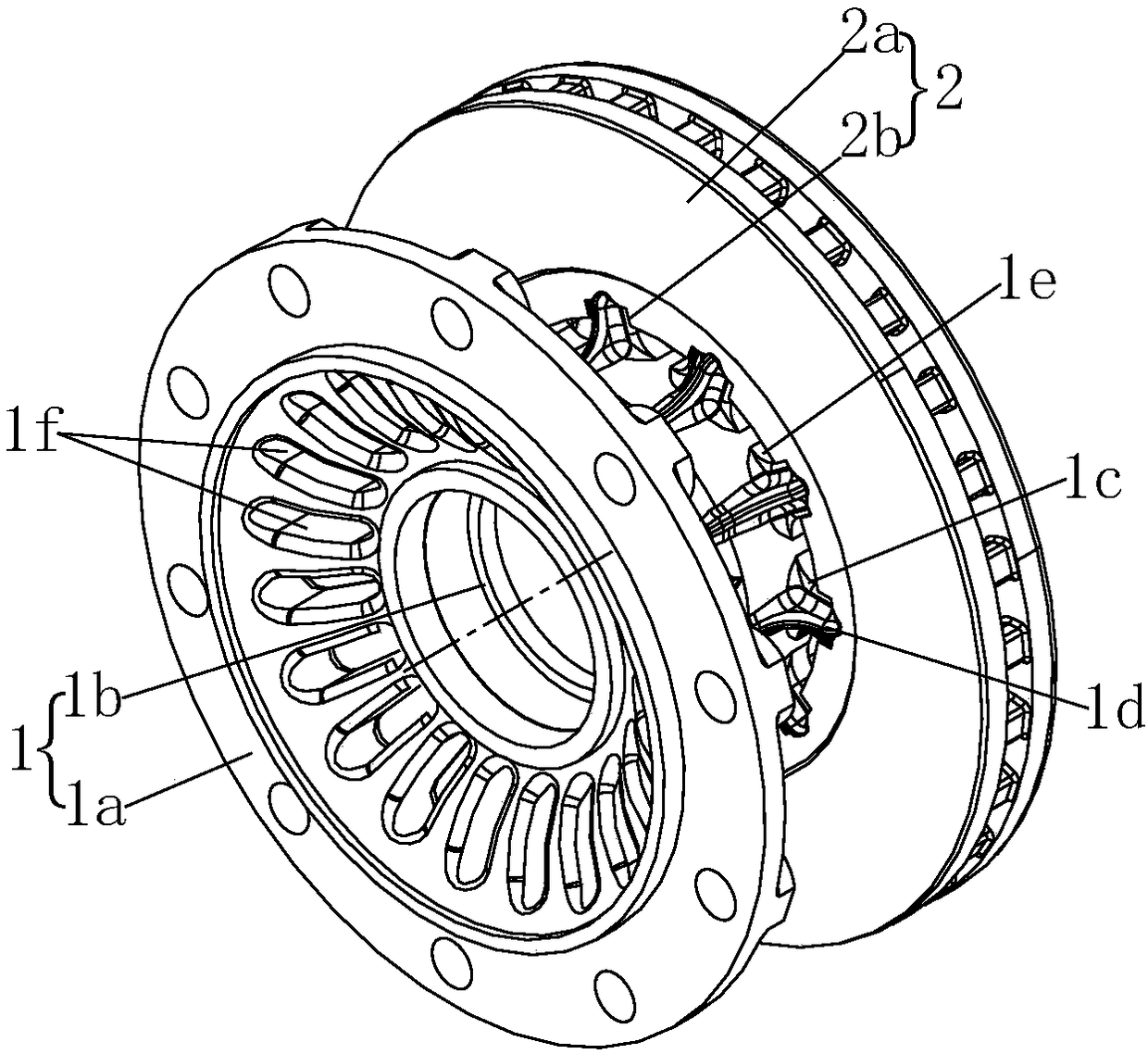

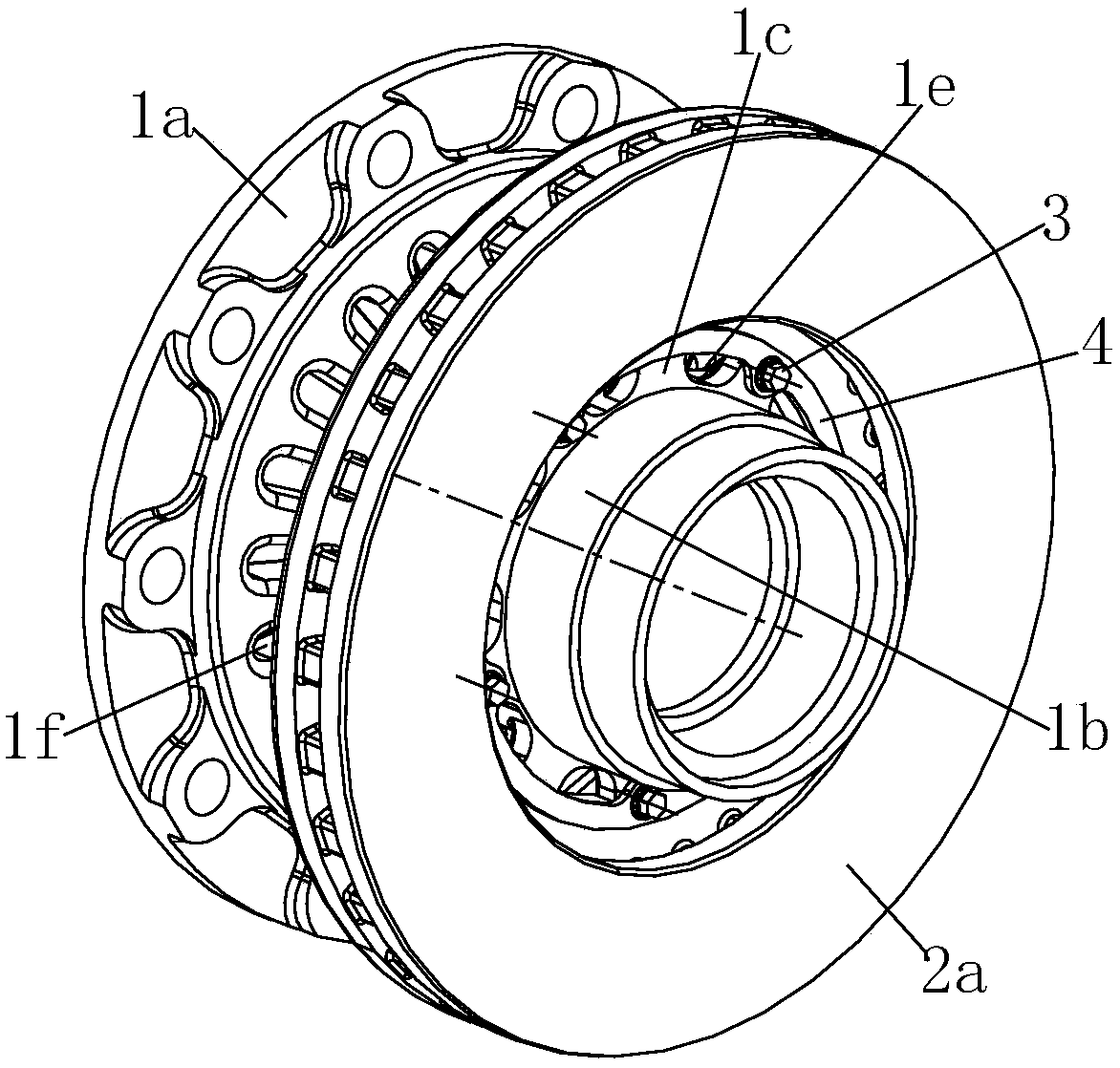

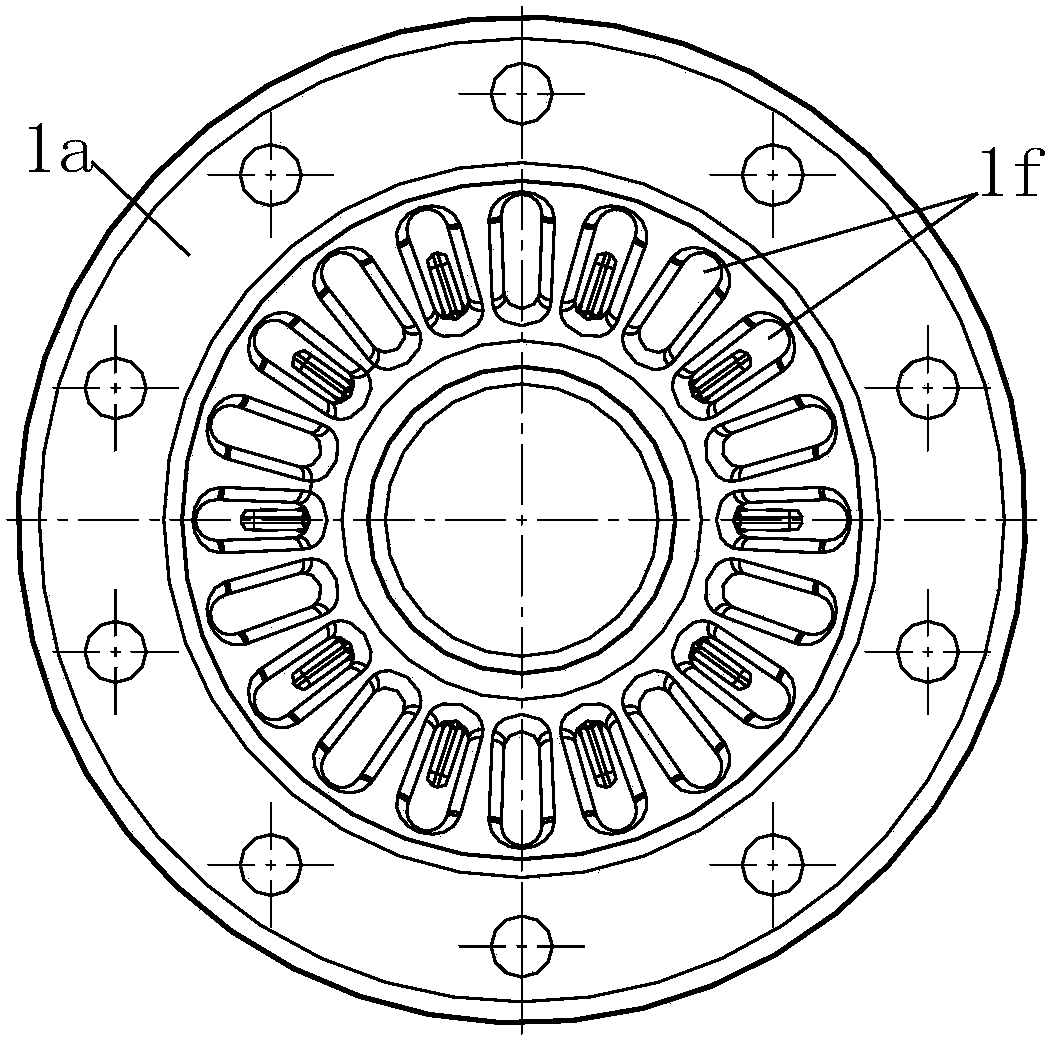

[0056] Embodiment: A screw-type hub brake disc assembly for commercial vehicles with heat dissipation, including a hub 1 and a brake disc 2, wherein the hub 1 is composed of a hub flange 1a and a hub bearing position 1b, and the The brake disc 2 includes a brake disc body 2a, the inner ring of the disc on the side of the brake disc body 2a facing the hub 1 is provided with several connecting key grooves 2b along the circumferential direction, and the hub bearing position 1b The position corresponding to the installation of the brake disc body 2a on the outer wall is provided with a connecting spline 1c matching with the connecting keyway 2b along the circumferential direction, and the brake disc body 2a is connected to the connecting keyway 2b through the connecting keyway 2b. The spline 1c is installed on the hub bearing position 1b, and the side of the connecting spline 1c facing the hub flange 1a is provided with a positioning reinforcing rib 1d at a position corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com