Swathing band type coupler

A type of coupling and wrapping technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of difficult to connect special-shaped shaft parts, limited application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

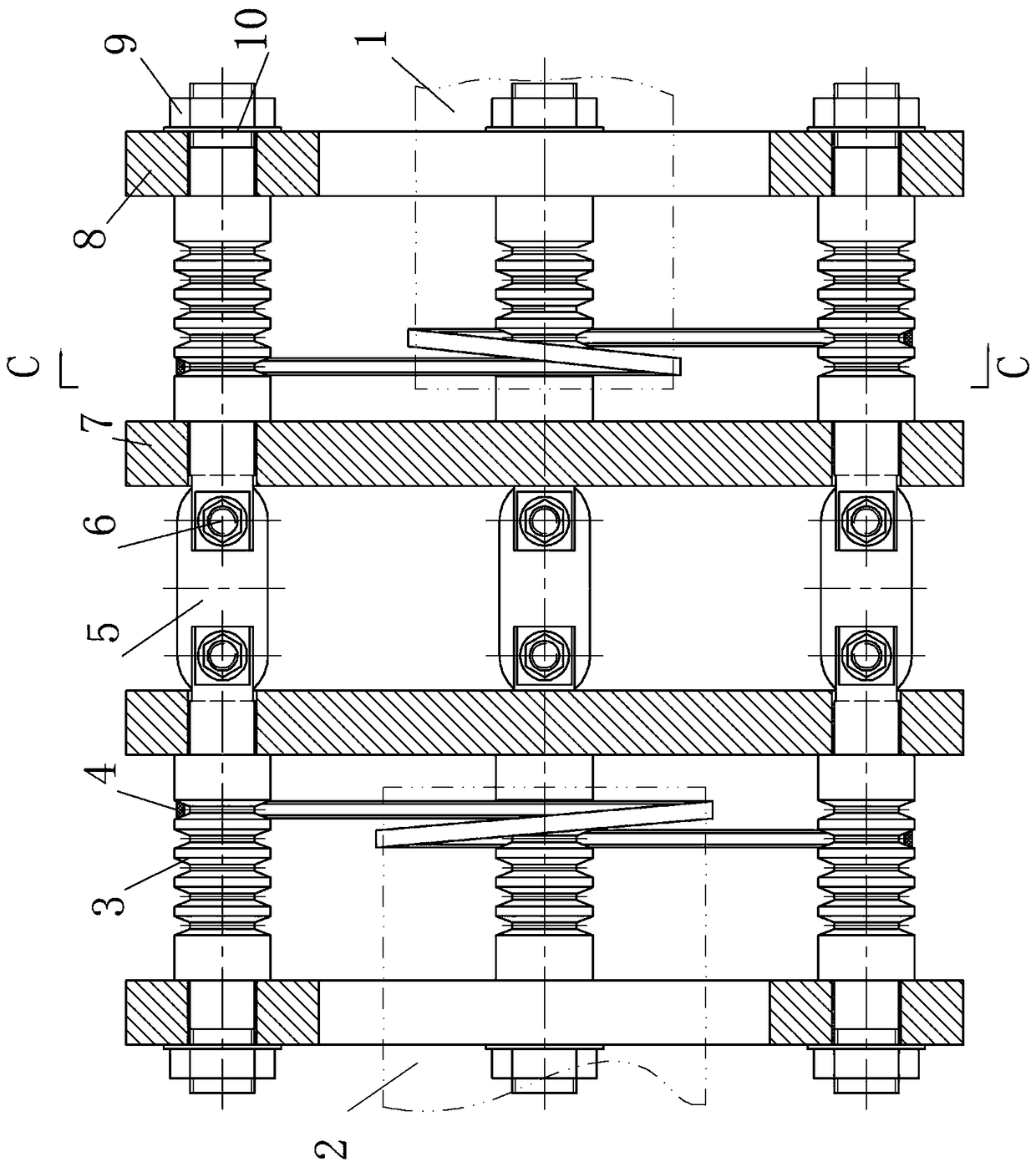

[0027] Embodiment one: see Figure 1-10 , a tape-winding coupling in the figure, including a coupling plate, a support plate, a coupling rod, a tape-winding rod, and a belt, is characterized by:

[0028] The middle part of the tape winding rod is a belt groove, and its two ends are respectively close to the connecting plate and the support plate, wherein, the end of the stepped shaft near the end of the support plate is threaded, one side of the support plate is close to the stepped surface of the stepped shaft, and the other side is connected to the tape. The rod is fastened by nuts and gaskets;

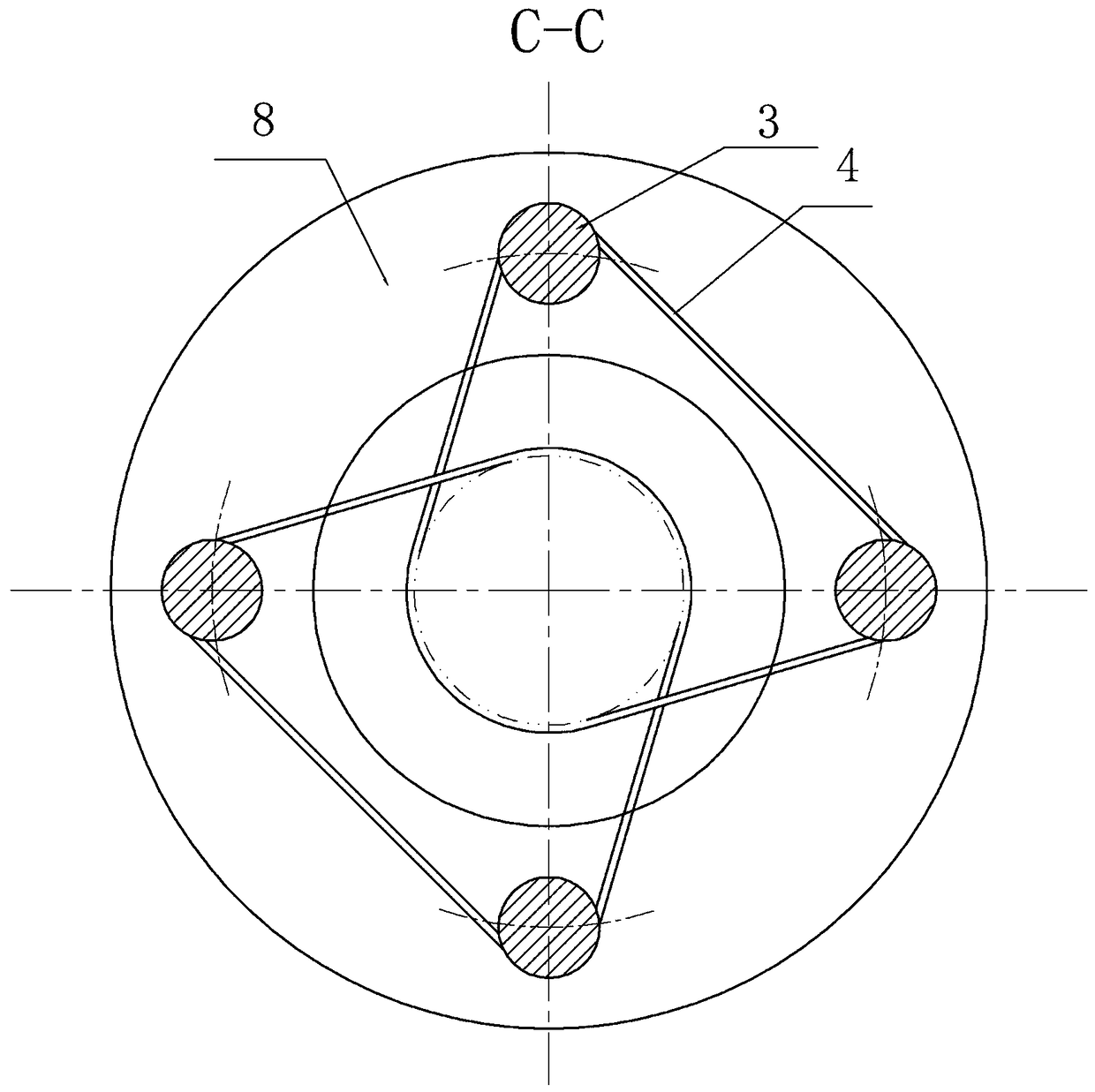

[0029] The connecting plate is disc-shaped, and there are four or eight through holes along the circumferential direction at its edge to allow the tape-wrapping rod to pass through;

[0030] The support plate is in the shape of a ring, and the middle part is used for passing the driving shaft or the driven shaft. There are four or eight through holes along the circumferential direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com