Semi-automatic book binding lower mould with feeding mechanism

A semi-automatic, feeding mechanism technology, which is applied to staple staple tools, staple tools, manufacturing tools, etc., can solve problems such as low production efficiency, and achieve high production efficiency, convenient operation and good binding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

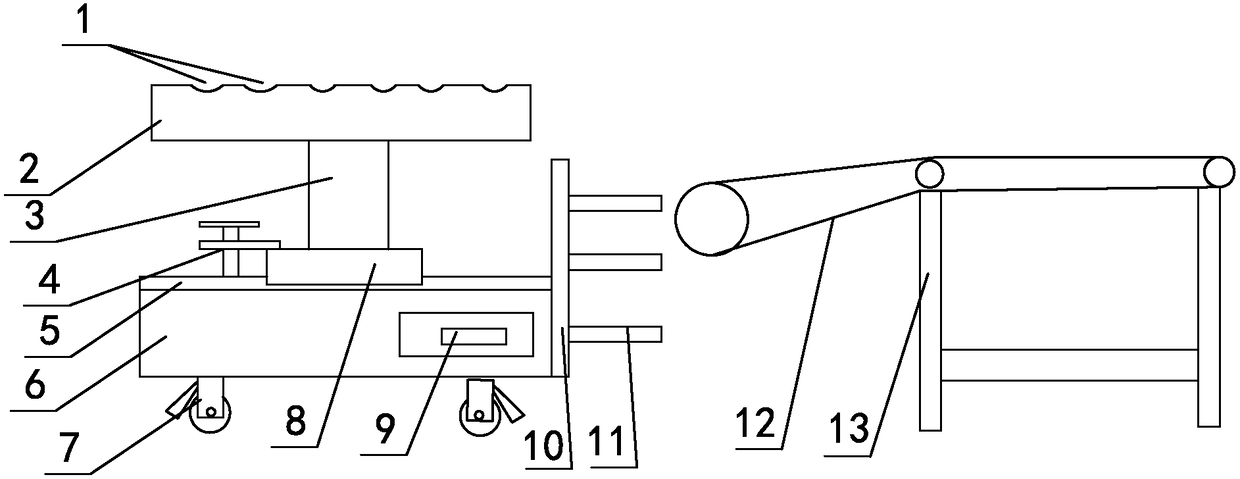

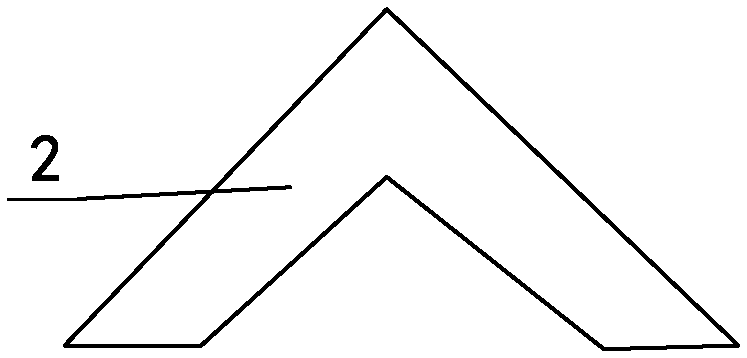

[0020] Such as figure 1 , figure 2 As shown, the semi-automatic lower die with a feeding mechanism includes a box body 6, at least three pulleys 7 that move left and right are arranged at the bottom of the box body 6, and slide rails 5 are horizontally arranged on the box body 6. The slide rail 5 is provided with a slide block 8 that slides and cooperates with the slide rail 5 left and right. The top of the slide block 8 is fixed with a connecting column 3, and the top of the connecting column 3 is horizontally fixed with a lower mold 2. On the lower mold 2, there are several pairs of pins for needles. The back needle slot 1 that is snapped back is vertically fixed with a mounting plate 10 on the right side of the box body 6, and several cross bars 11 are horizontally arranged on the mounting plate 10, and a belt for transporting to the right is provided on the right side of the cross bar 11. Conveyor 12, belt conveyor 12 is installed on the bracket 13, on the casing 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com