Mandibular condyle motion track measuring method for manufacturing mandibular condyle prosthesis

A technology of movement trajectory and mandible, which is applied in the direction of prosthesis, application, skull, etc., can solve the problem of inability to accurately measure the movement trajectory of the mandible, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

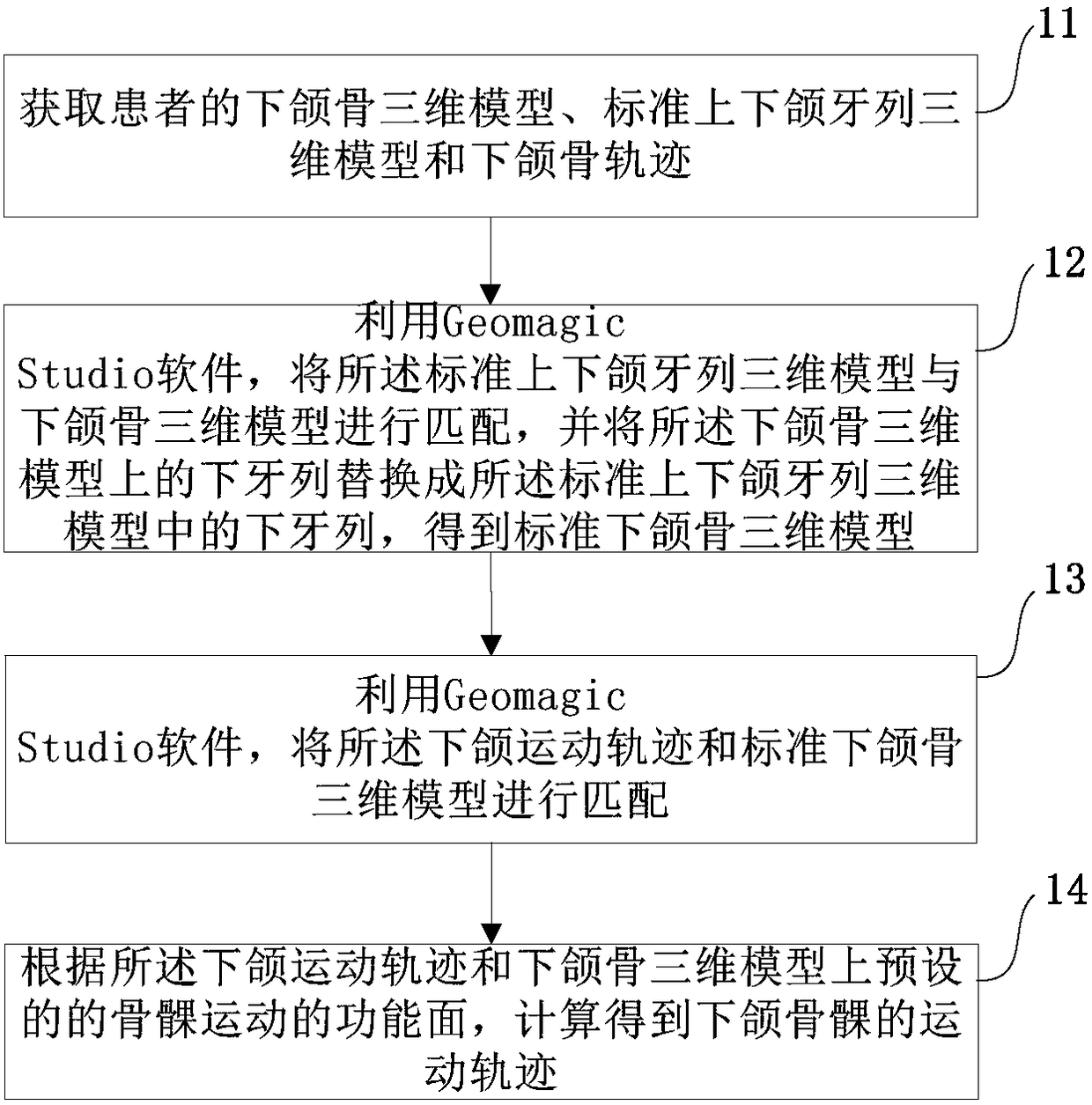

[0030] see figure 1 , the application provides a method for measuring the motion track of the mandibular condyle for the manufacture of the mandibular condyle prosthesis, including:

[0031] Step 11: Obtain the patient's mandibular three-dimensional model, the standard three-dimensional model of the upper and lower jaw dentition, and the mandibular movement trajectory.

[0032] Step 12: Using Geomagic Studio software, match the standard three-dimensional model of the upper and lower jaw dentition with the three-dimensional model of the mandible, and replace the lower dentition on the three-dimensional mandible model with the one in the three-dimensional model of the standard upper and lower jaw dentition The lower dentition, to obtain a standard 3D model of the mandible.

[0033] Image registration is performed on the 3D model data of the two data modalities, so that the corresponding 3D point set X of the two sets of graphic data A (x1,y1,z1) and x N (x2, y2, z2) to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com