Plan optimization method used for supply chain of chemical enterprise

An optimization method and supply chain technology, applied in the field of optimization, can solve problems such as raw material supply, planning, maintenance and inventory inconsistency, frequent changes in business processes, and asymmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

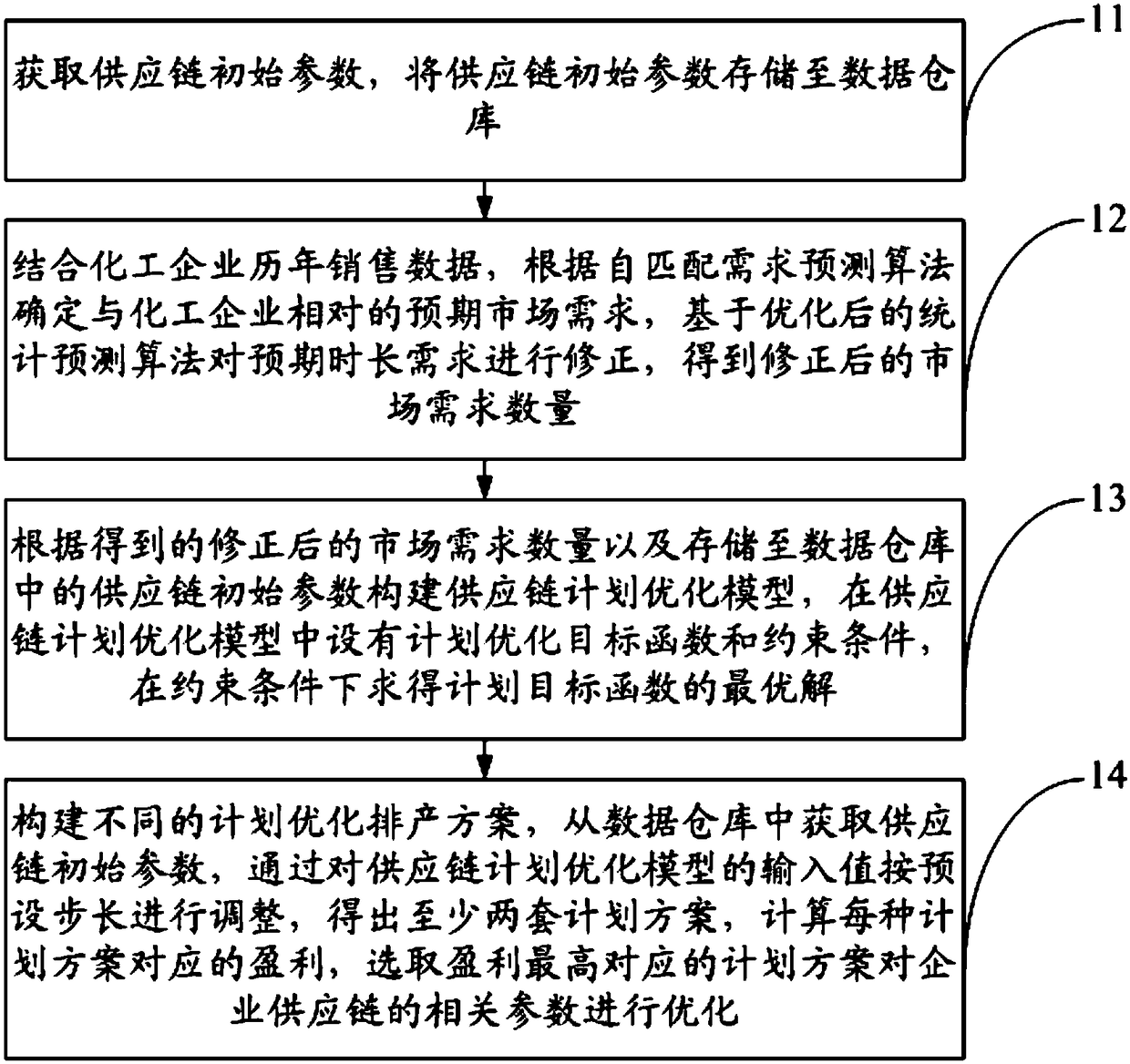

[0068] The present invention provides in order to achieve the above-mentioned technical purpose, the present invention provides the plan optimization method that is used for chemical enterprise supply chain, such as figure 1 As shown, the plan optimization method includes:

[0069] 11. Obtain the initial parameters of the supply chain and store the initial parameters of the supply chain in the data warehouse;

[0070] 12. Combining the sales data of chemical companies over the years, determine the expected market demand relative to chemical companies based on the self-matching demand forecasting algorithm, and correct the expected time-length demand based on the optimized statistical forecasting algorithm to obtain the corrected market demand quantity;

[0071] 13. Construct a supply chain planning optimization model based on the corrected market demand and the initial parameters of the supply chain stored in the data warehouse. In the supply chain planning optimization model,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com