Single-slips fully-soluble bridge plug

A single slip and bridge plug technology, applied in the field of single slip fully soluble bridge plug, can solve the problems of insoluble slips, difficult drilling and grinding of coiled tubing, and inability to inspect and seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

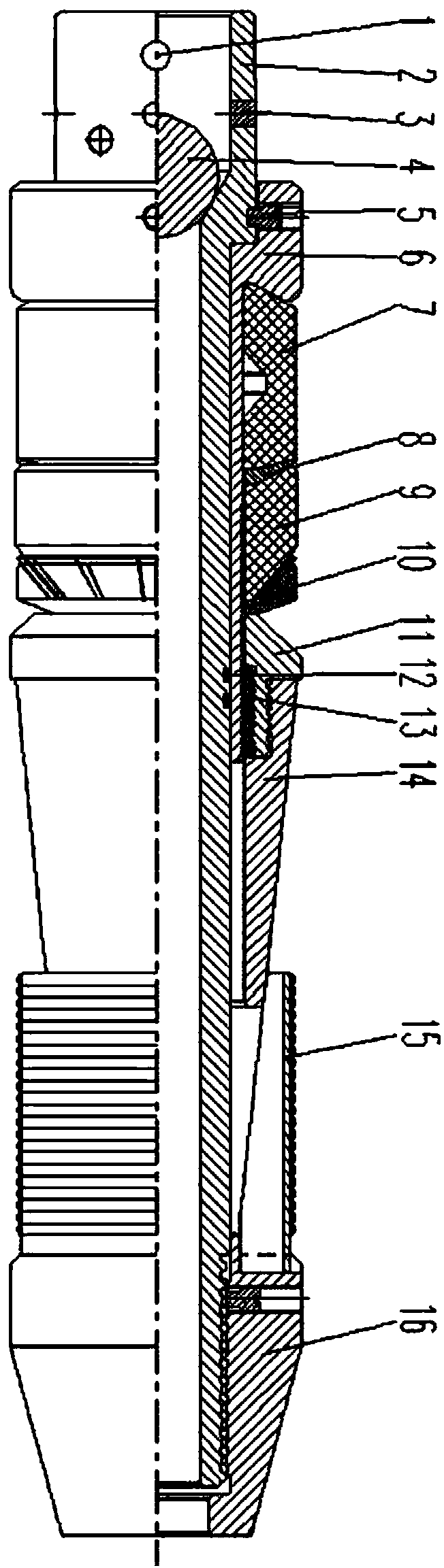

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

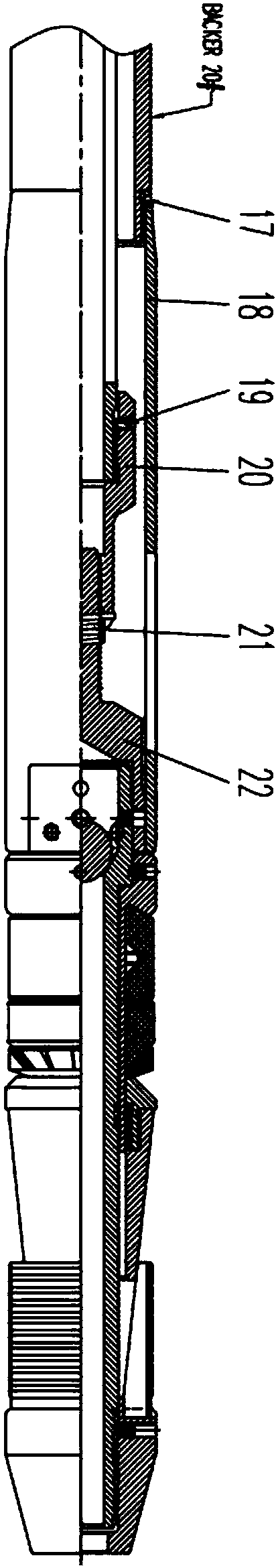

[0019] like figure 1 A single-slip fully soluble bridge plug is shown, including insert rod 1, central tube 2, shear pin 3, fracturing ball 4, activation pin 5, sliding sleeve 6, rubber cylinder 7, spacer ring 8, end Rubber cartridge 9, back ring 10, lock ring back ring 11, O-shaped seal ring 12, lock ring 13, cone 14, slips 15 and guide shoes 16, the central tube 2 is an axial hollow structure, and the central tube 2 The upper end is provided with an intubation tube 1 connected to the outside and a plurality of evenly distributed shear pins 3. The upper end of the central tube 2 is provided with a variable diameter cavity for placing fracturing balls 4. The cross-sectional taper of the variable diameter cavity is 20- 30°, the fracturing ball 4 is a dissolvable fracturing ball, the sliding sleeve 6 and the back ring 10 are arranged outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com