A combined process method for heavy oil conversion

A combined process and heavy oil technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., can solve limited and reduce coke yield and other problems, and achieve the effect of prolonging the operation cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

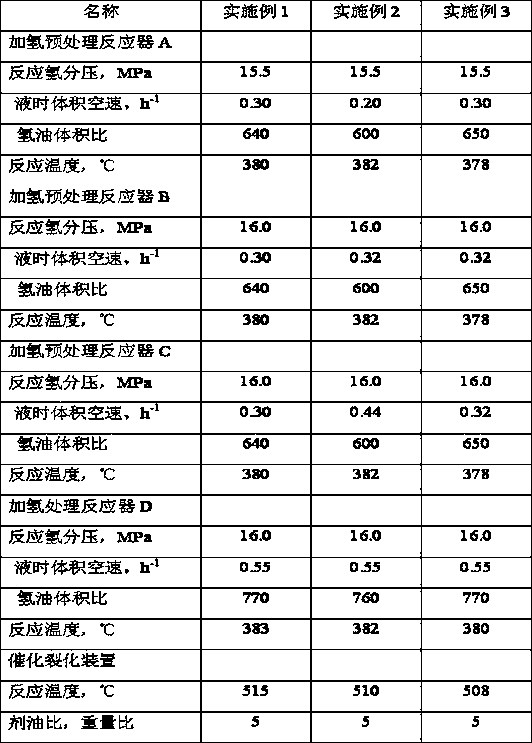

Embodiment 1

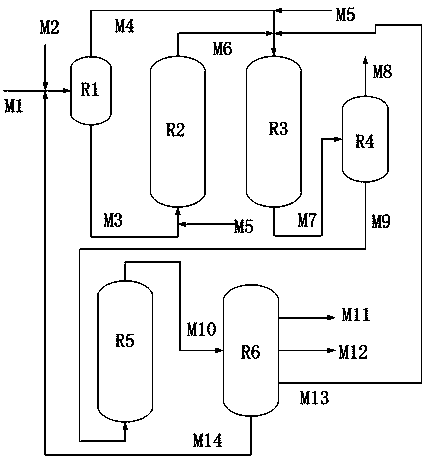

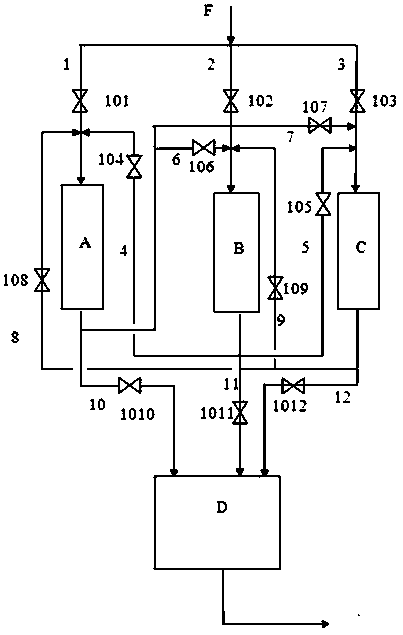

[0091] In this example, a combined process of solvent deasphalting, ebullating bed, fixed bed, and catalytic cracking is used to carry out heavy oil hydroconversion. Firstly, the raw material oil A is uniformly mixed with butane solvent, and then enters the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt, and after preheating, the deoiled asphalt is mixed with hydrogen and enters the ebullated bed hydrotreating device for hydrogenation reaction, deasphalting Remove sulfur, nitrogen, metal and other heteroatoms in raw materials, and at the same time convert asphaltenes into colloids or smaller molecules, reduce product viscosity, and separate hydrogenation products to obtain liquid phase oil, which is mixed with deasphalted oil into The reaction is carried out in the fixed bed hydrogenation unit, and the resulting oil enters the catalytic cracking unit for further cracking and conversion into dry gas, catalytic cracking gasoline, catalytic cracking dies...

Embodiment 2

[0093] Raw material B is used as described in Example 2, and its properties are shown in Table 1. Example 2 The ebullated bed reactor uses a mixed catalyst with a volume ratio of catalyst A and catalyst B of 1:0.4.

Embodiment 3

[0095] Raw material C is used as described in Example 3, and its properties are shown in Table 1. Example 3 The ebullated bed reactor uses a mixed catalyst with a volume ratio of catalyst A and catalyst B of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com