Sliding frictional force generation mechanism and manufacture method thereof, mold buffer device and metal die

A technology of sliding friction force and buffer device, applied in manufacturing tools, presses, etc., can solve the problem of not using friction force, etc., and achieve the effect of high oil film maintenance, improved cooling efficiency, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

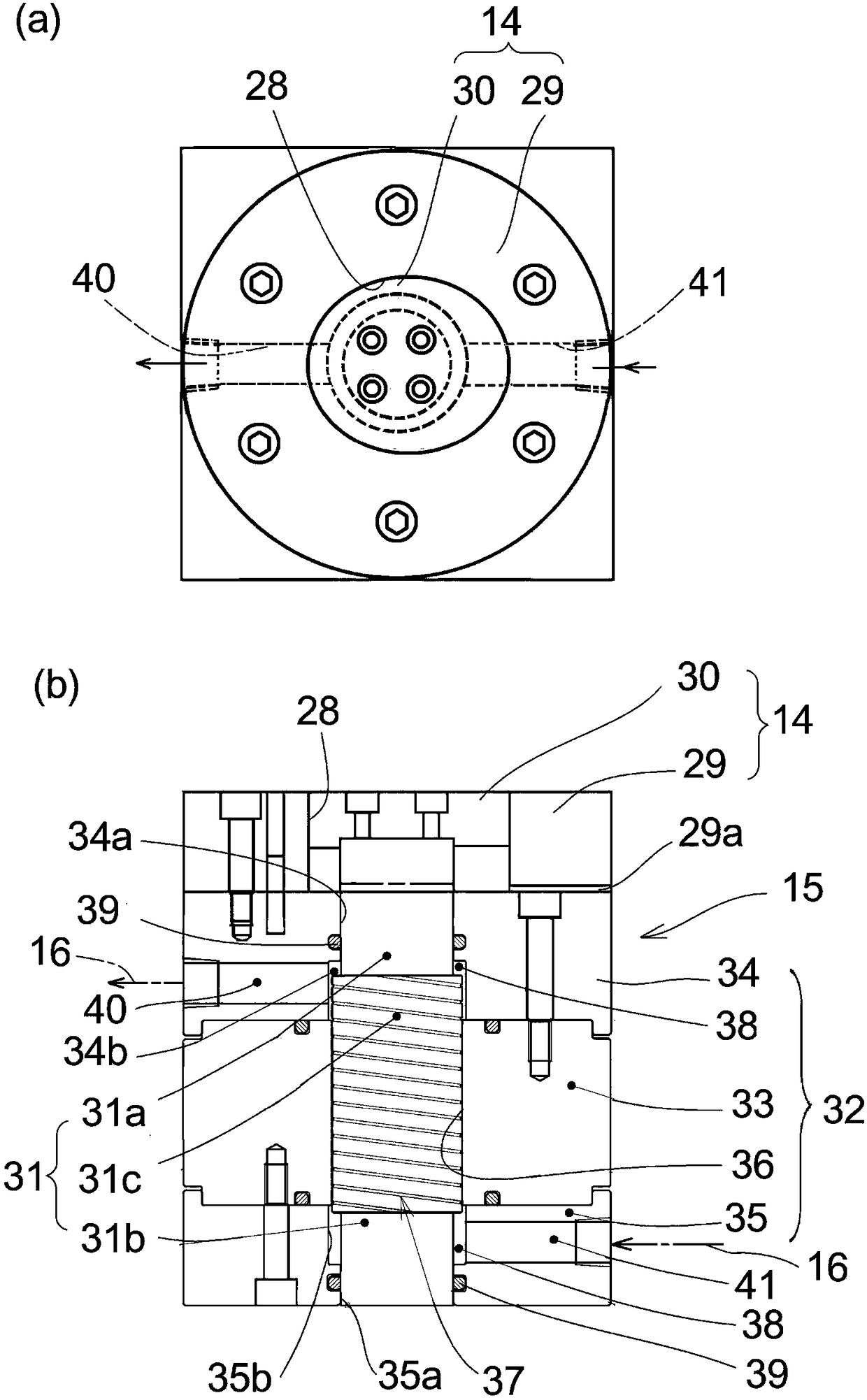

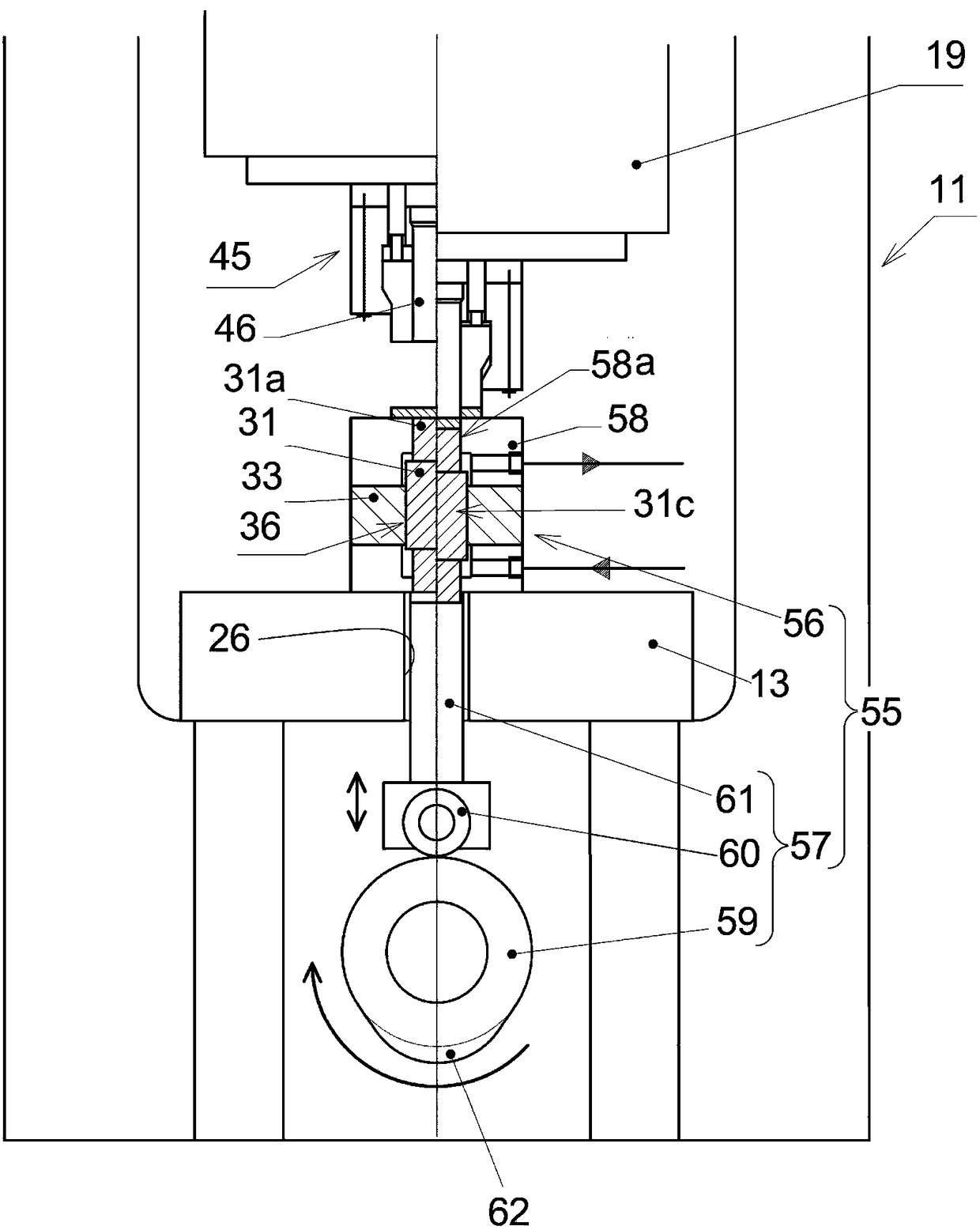

[0053] figure 1 , figure 2 a and figure 2 The mold buffer device 10 shown in b is composed of a normal-pressure air buffer device 12 installed on the press machine 11 and arranged under the backing plate 13, and combined with the lower part of the lower mold 14 arranged on the backing plate 13. The friction die buffer 15 constitutes. Reference numeral 16 is a supply system for supplying and circulating lubricating oil which also serves as cooling oil to the friction die cushion 15 . figure 1 The left side of is the state that the slider of press machine 11 is rising, and the right side is the state of falling. exist image 3 , Figure 4 It is the same in a. The press machine 11 is composed of a frame 18, the above-mentioned backing plate 13, a slider 19 that moves up and down, and a known slider driving mechanism (not shown) that drives the slider up and down.

[0054] The air cushion device 12 includes a multi-stage bellows 20, air (pressurized air) filled inside, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com