High-precision high-rigidity prestress support

A pre-stressed, high-rigidity technology, applied in the field of precision equipment manufacturing, can solve the problems of unreliable repetitive positioning accuracy, low accuracy, and insufficient rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

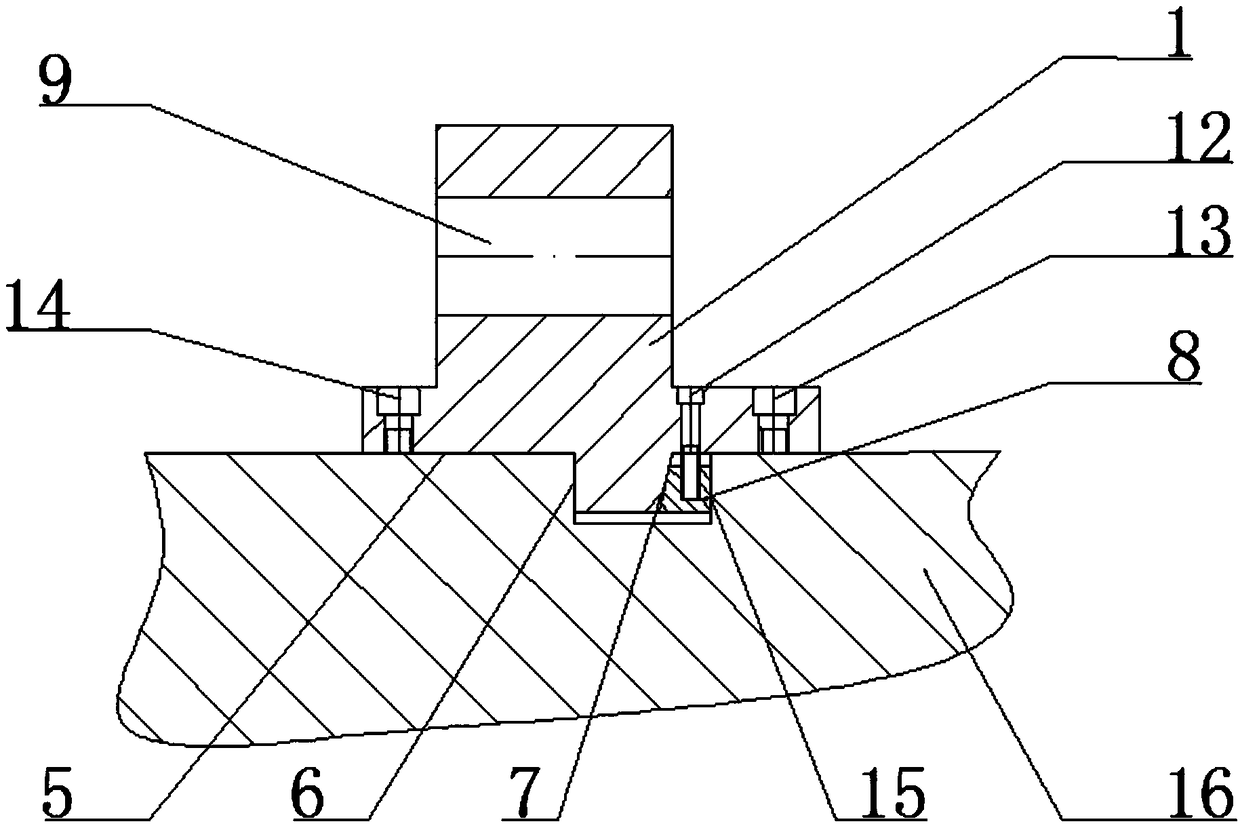

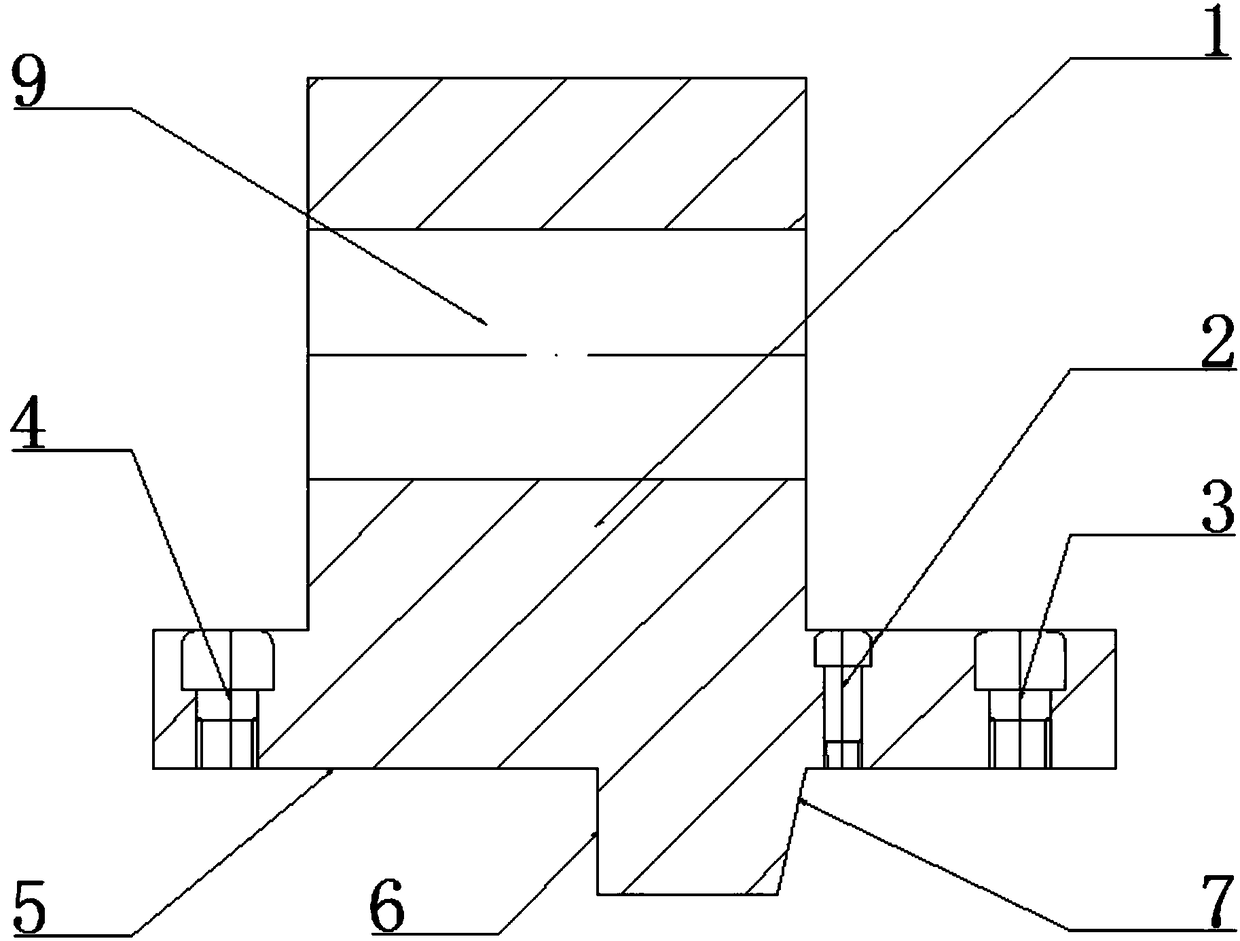

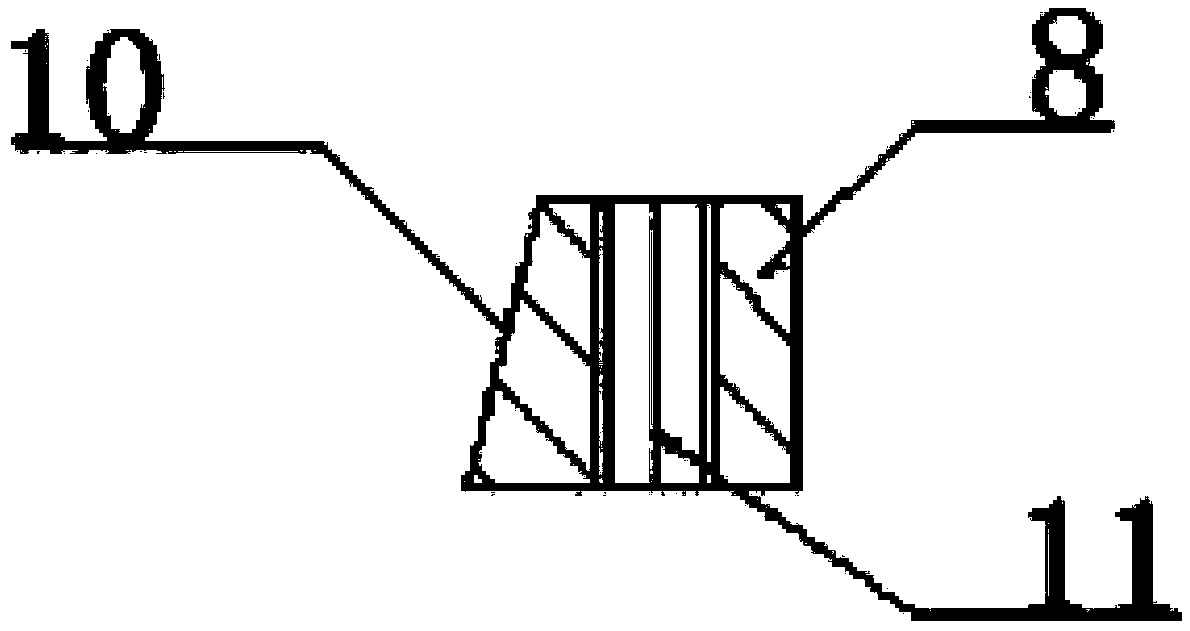

[0011] like figure 1 figure 2 image 3 As shown, the support body (1) is a special-shaped structural part, and its upper part is provided with a driving mechanism installation hole (9), and its lower part is provided with a joint surface (05) installed with the mechanical main body (16), a positioning surface (6), a pre-set The stress slope (7) and mounting screw holes (2, 3, 4) are used for mounting screws (12, 13, 14) to fix the support body; the oblique key (8) is a wedge-shaped structure, and one side (15) is used for positioning , the wedge surface (10) is used to increase the force to improve the prestress of the support body installation, and is provided with a mounting screw hole (11) for installing the screw (12) and tightening the oblique key, so as to achieve the effect of increasing force and preloading.

[0012] When in use, the support body (1), the oblique key (8) and the mounting screws (12, 13) are formed into an assembly, pre-installed in the mounting groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com