Novel livestock and poultry biological veterinary drug preparation device

A technology for preparing devices, livestock and poultry, applied in mixers with rotary stirring devices, transportation and packaging, chemical/physical processes, etc., can solve the problems of high labor intensity, uneven stirring, difficult quantitative packaging work, etc. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

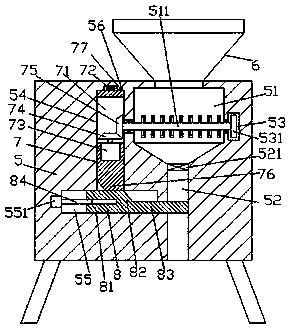

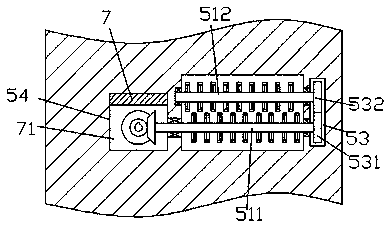

[0011] Combine below Figure 1-Figure 3 The present invention will be described in detail.

[0012] refer to Figure 1-Figure 3 , according to an embodiment of the present invention, a novel livestock and poultry biological veterinary drug preparation device includes a main body 5, a stirring chamber 51 is arranged inside the main body 5, and the top end surface of the main body 5 on the upper side of the stirring chamber 51 A feed hopper 6 connected to the stirring chamber 51 is fixed on the top, and the inner bottom wall of the stirring chamber 51 is connected to a discharge channel 52 extending downward, and the bottom of the discharge channel 52 extends at the end Through the bottom end surface of the main body 5, an electric control valve 521 is fixed at the connection between the discharge channel 52 and the stirring chamber 51, and a downward valve is provided in the inner wall of the main body 5 on the left side of the stirring chamber 51. Extended first sliding cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com