A method for slowing down the discoloration rate of green tea surface

A technology of speed and green tea, applied in the field of slowing down the discoloration rate of green tea surface, can solve the problems of destroying green tea leaves and losing the natural color of green tea surface, and achieve the effect of saving process and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

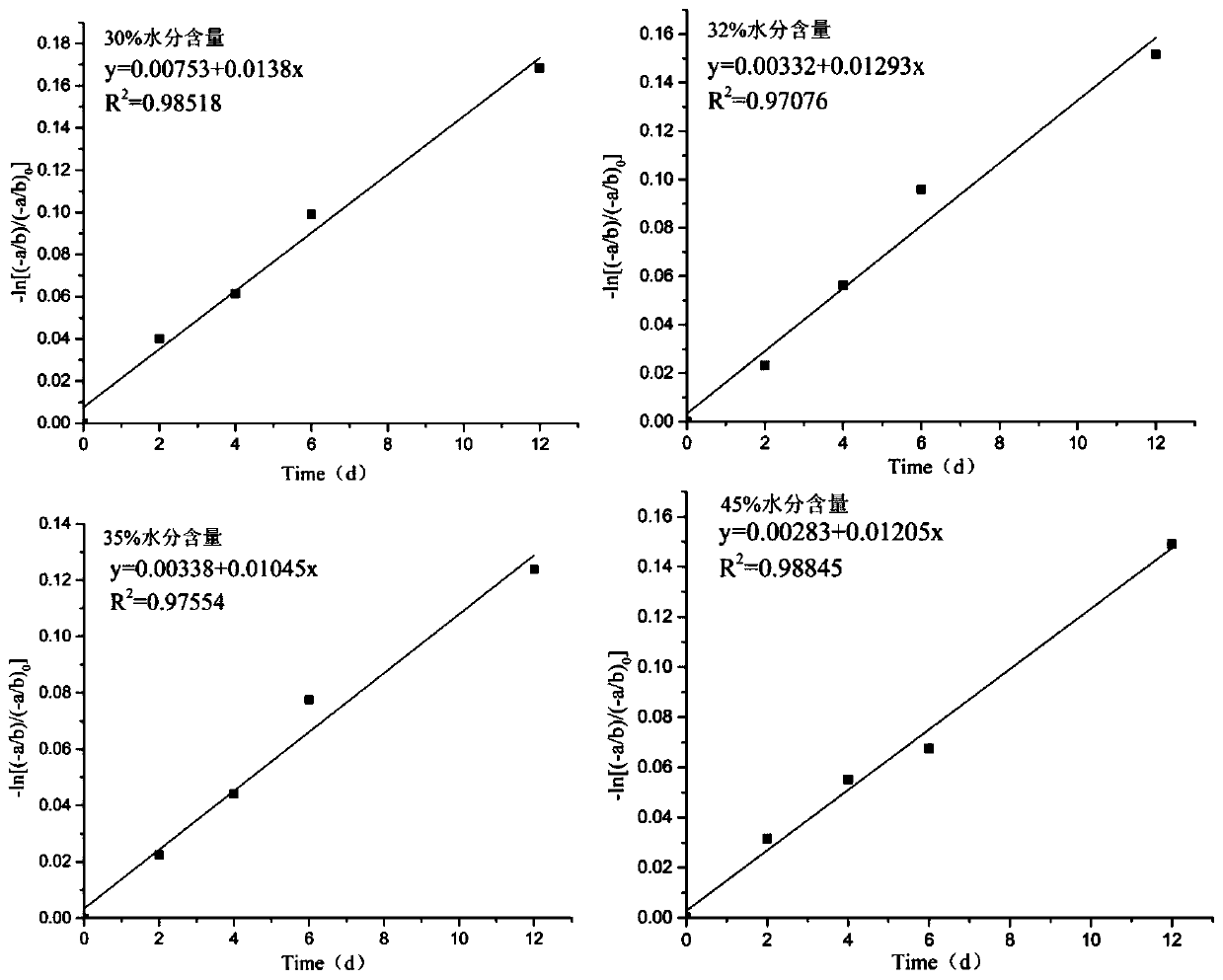

Method used

Image

Examples

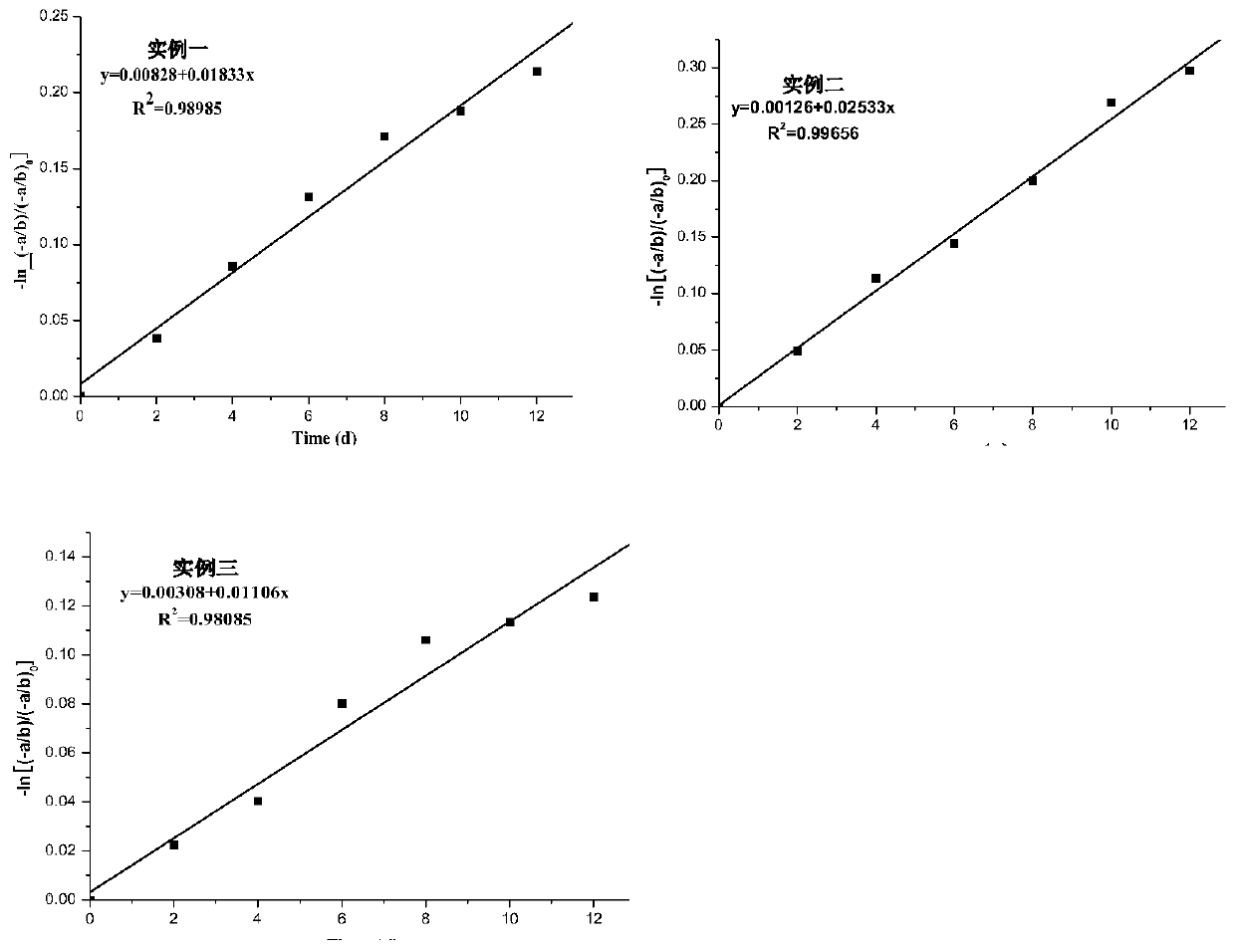

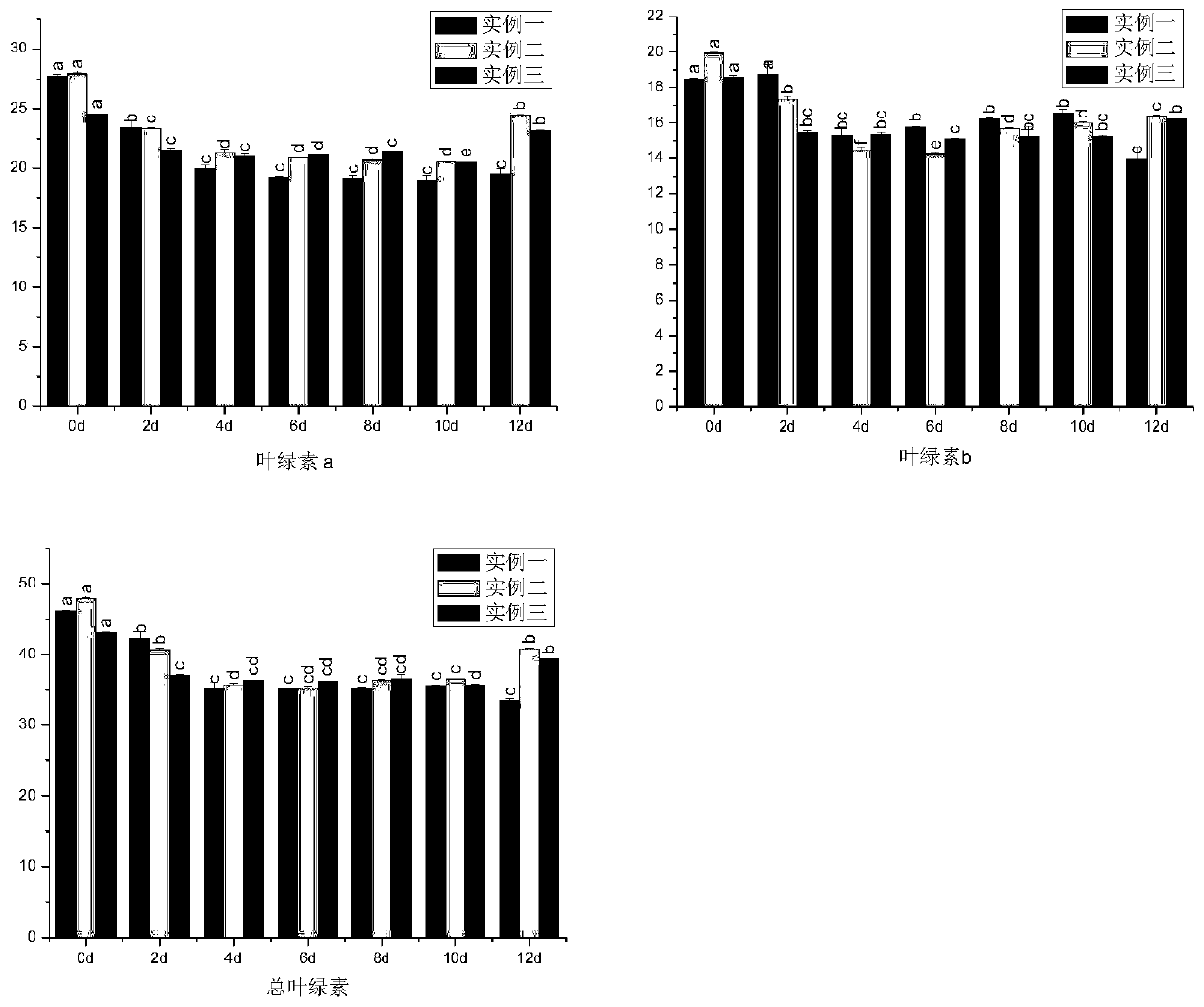

Embodiment 1

[0032] After mixing 4g of superfine green tea powder with 200g of wheat flour for 1min, add 70g of water, and after forming a dough, roll according to the method in Example 2, cut into shreds, and dry to make green tea noodles. The calendering steps are: 8 times of 2 mm pressing, 5 times of 1.5 mm pressing, and 1 mm pressing twice. The drying steps are as follows: 36°C for 30min, humidity 80%; 40°C for 40min, humidity 70%; 45°C for 180min, humidity 60%; 40°C for 30min, humidity 60%; 30°C for 30min , with a humidity of 60%.

Embodiment 2

[0034] Add 40 g of deoxygenated water to 4 g of tea powder, mix and vortex for 10 min and then centrifuge at 3500 r / min for 15 min. Obtain about 30g of tea powder water-soluble matter and about 14g of tea dregs; Add 30g deoxygenated water in the obtained 30g tea powder water-soluble matter, the tea powder water-soluble matter is mixed with 200g wheat flour and form dough; The dough obtained is mixed with 14g of Tea dregs are mixed and formed into dough; calendered, shredded, and dried; the drying steps are as follows: 36°C for 30 minutes, humidity 80%; 40°C for 40 minutes, humidity 70%; 45°C for 180 minutes, humidity 60% %; 40°C for 30 minutes, the humidity is 60%; 30°C for 30 minutes, the humidity is 60%. The calendering steps are: 8 times of 2 mm pressing, 5 times of 1.5 mm pressing, and 1 mm pressing twice.

Embodiment 3

[0036] Add 40 g of deoxygenated water to 4 g of tea powder, mix and vortex for 10 min and then centrifuge at 3500 r / min for 15 min. Obtain about 30g of tea powder water-soluble matter and tea grounds about 14g; Add 30g water in the obtained 30g tea powder water-soluble matter, mix with 200g wheat flour and form dough after adding 35% water into the tea powder water-soluble matter, Put the dough in a water bath at 80°C and heat it for 15 minutes; take out the heated dough, mix 14g of tea dregs into it and form a dough, then roll, shred, and dry to make green tea noodles; the drying steps are as follows: : 36°C for 30min, humidity 80%; 40°C for 40min, humidity 70%; 45°C for 180min, humidity 60%; 40°C for 30min, humidity 60%; 30°C for 30min, humidity 60% . The calendering steps are: 8 times of 2 mm pressing, 5 times of 1.5 mm pressing, and 1 mm pressing twice.

[0037] Table 1 Texture properties of green tea noodles prepared by different methods

[0038]

[0039] It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com