Wood floor with high utilization rate, connection assembly and connection structures of wood floor and connection assembly

A technology of connecting components and utilization rate, which is applied in the direction of building structure, floor, building, etc., to achieve the effect of saving man-hours, saving the use of wood, and laying simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

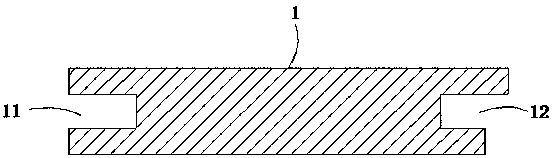

[0027] See figure 1 , the present invention provides a high-utility wooden floor, including a floor body 1, one side of the floor body 1 is provided with a first groove 11 along the horizontal direction, and the other side of the floor body 1 is provided with a second groove 12 along the horizontal direction , in this embodiment, the second groove 12 is provided with a notch, and the length of the upper side of the second groove 12 is greater than the length of the lower side.

[0028] In this embodiment, the cross sections of the first groove 11 and the second groove 12 are both rectangular.

[0029] The depth of the first groove 11 is greater than the depth of the second groove 12 .

Embodiment 2

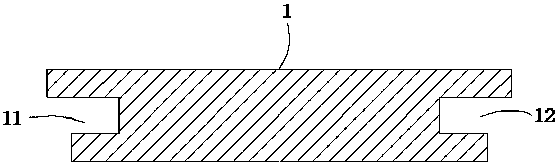

[0031] See figure 2 , the present invention provides a high-utility wooden floor, including a floor body 1, one side of the floor body 1 is provided with a first groove 11 along the horizontal direction, and the other side of the floor body 1 is provided with a second groove 12 along the horizontal direction , in this embodiment, the first groove 11 and the second groove 12 are provided with gaps, the length of the upper side of the first groove 11 is greater than the length of the lower side, and the length of the upper side of the second groove 12 is greater than The length of the lower side.

[0032] In this embodiment, the cross sections of the first groove 11 and the second groove 12 are both rectangular.

Embodiment 3

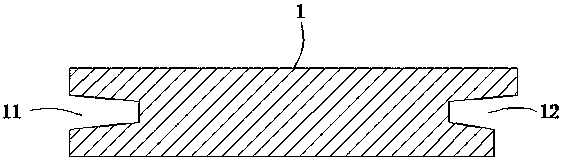

[0034] See image 3 , the present invention provides a high-utility wooden floor, including a floor body 1, one side of the floor body 1 is provided with a first groove 11 along the horizontal direction, and the other side of the floor body 1 is provided with a second groove 12 along the horizontal direction , in this embodiment, the second groove 12 is provided with a notch, and the length of the upper side of the second groove 12 is greater than the length of the lower side.

[0035] In this embodiment, the cross-sections of the first groove 11 and the second groove 12 gradually widen in width from the inside to the outside, for example, the cross-sections of the first groove 11 and the second groove 12 are trumpet-shaped.

[0036] The depth of the first groove 11 is greater than the depth of the second groove 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com