Production method of light-emitting suspended ceiling formwork and light-emitting suspended ceiling formwork

A technology of ceiling panels and templates, which is applied to semiconductor devices, ceilings, and optics of light-emitting elements, and can solve problems such as unfavorable space, melting of line insulation layers, and loss of adhesion, and achieve space-saving, uniform light efficiency, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

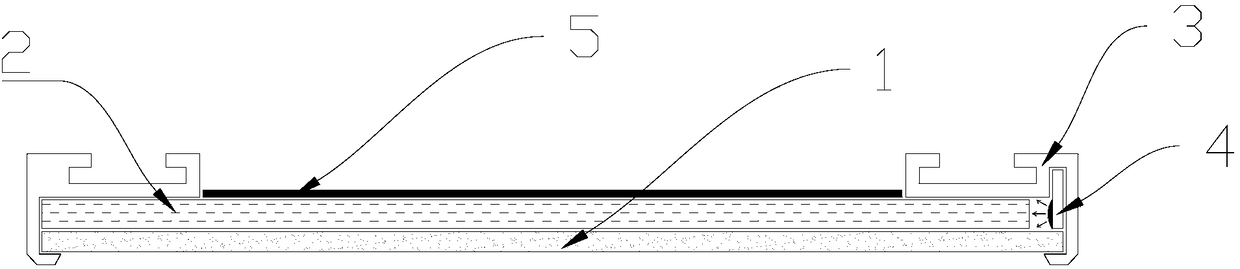

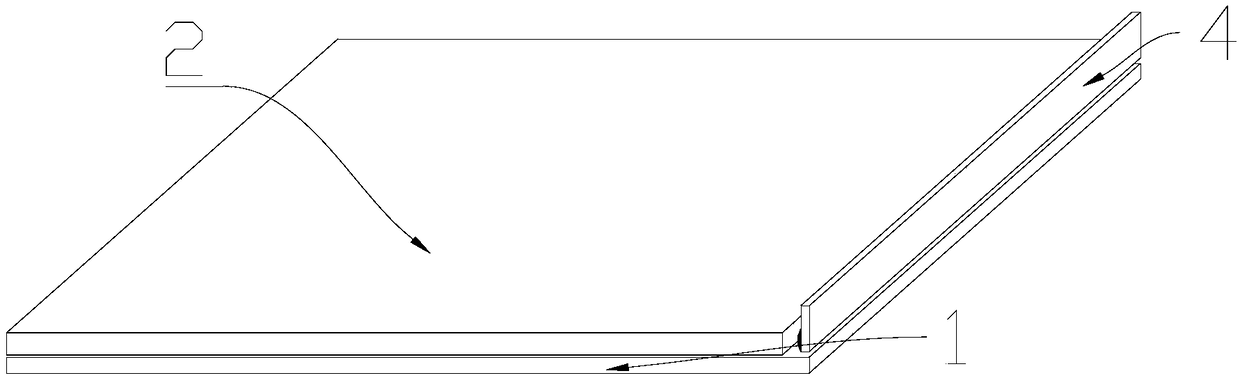

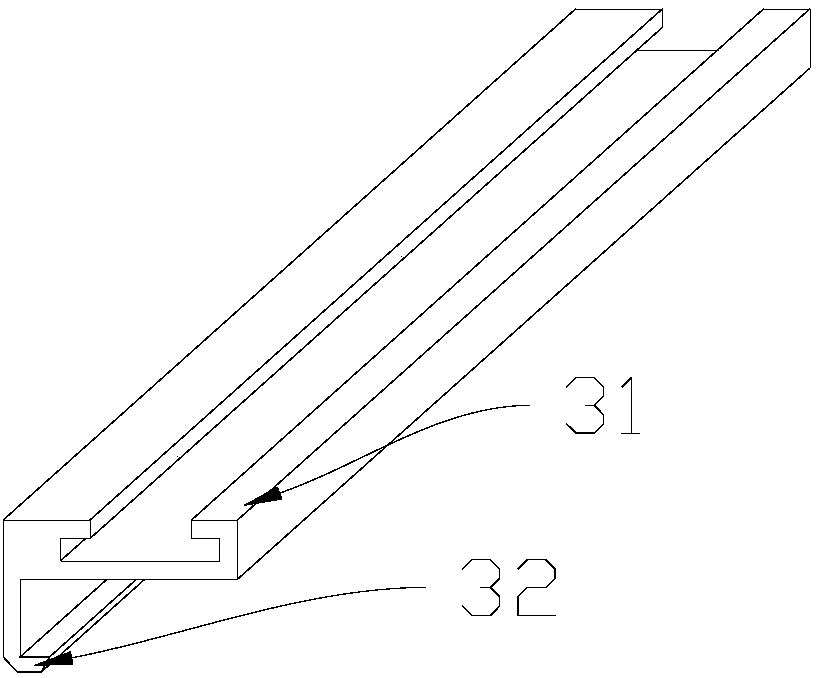

[0031] see Figure 1-Figure 3 , the invention provides a method for preparing a luminous ceiling template, comprising the following steps:

[0032] Step S1: cutting the decorative panel layer to obtain a rectangular decorative panel layer finished product 1;

[0033] Step S2: cutting the PMMA light guide plate to obtain a rectangular light guide plate finished product 2, and the length of the finished light guide plate finished product 2 is equal to the length of the decorative panel layer finished product 1, and the width of the light guide plate finished product 2 is smaller than the width of the decorative panel layer finished product 1 by 2 -5mm;

[0034] Step S3: using a laser to burn the upper surface of the finished light guide plate 2 to form burning spots, and in the width direction of the finished light guide plate 2, the density of the burning spots decreases from left to right;

[0035] Step S4: bonding the upper surface of the finished product 1 of the decorativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com