Explosion center positioning device

A technology of positioning device and measuring device, applied in the direction of measuring device, using mechanical device, mechanical measuring device, etc., can solve the problems of high maintenance cost, limited range of measurable angles, affecting the normal test of explosion parameters, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

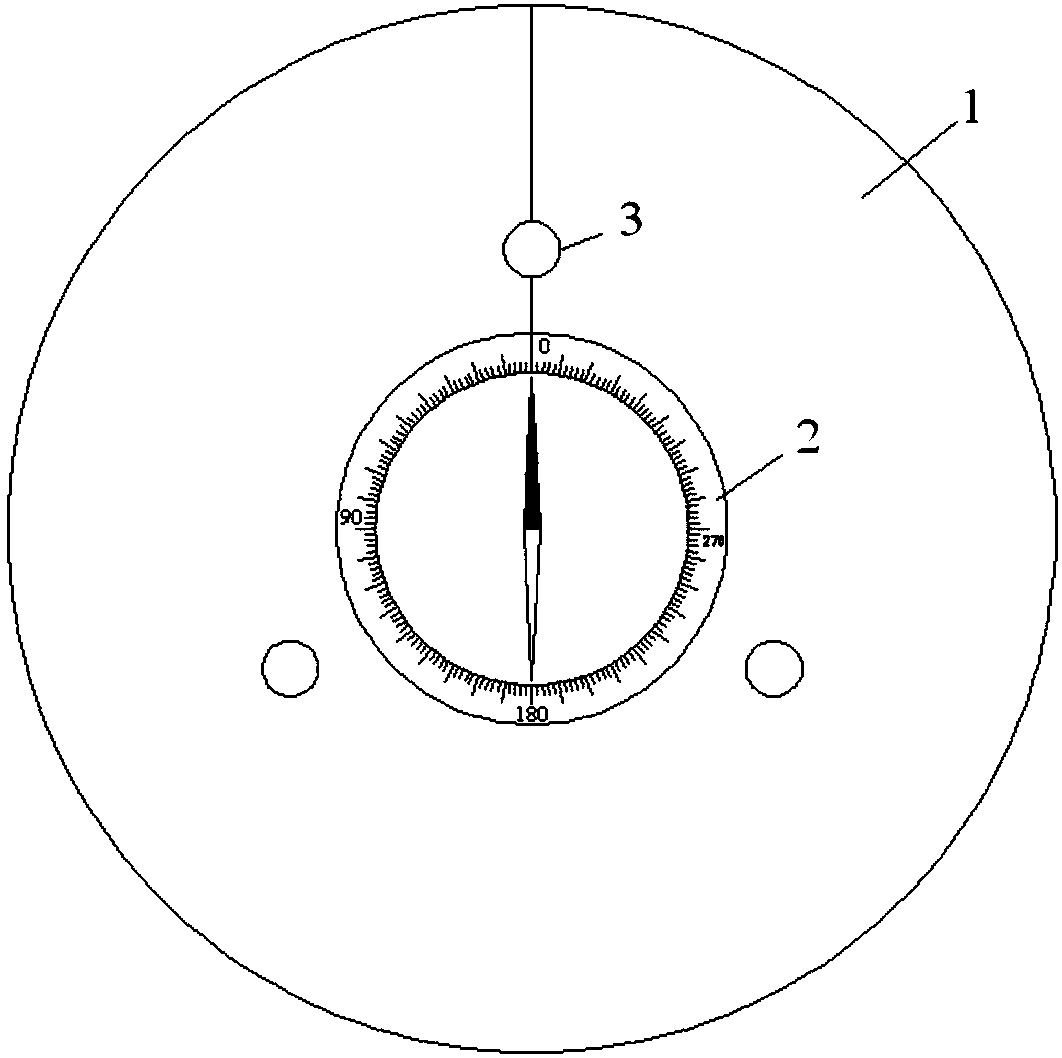

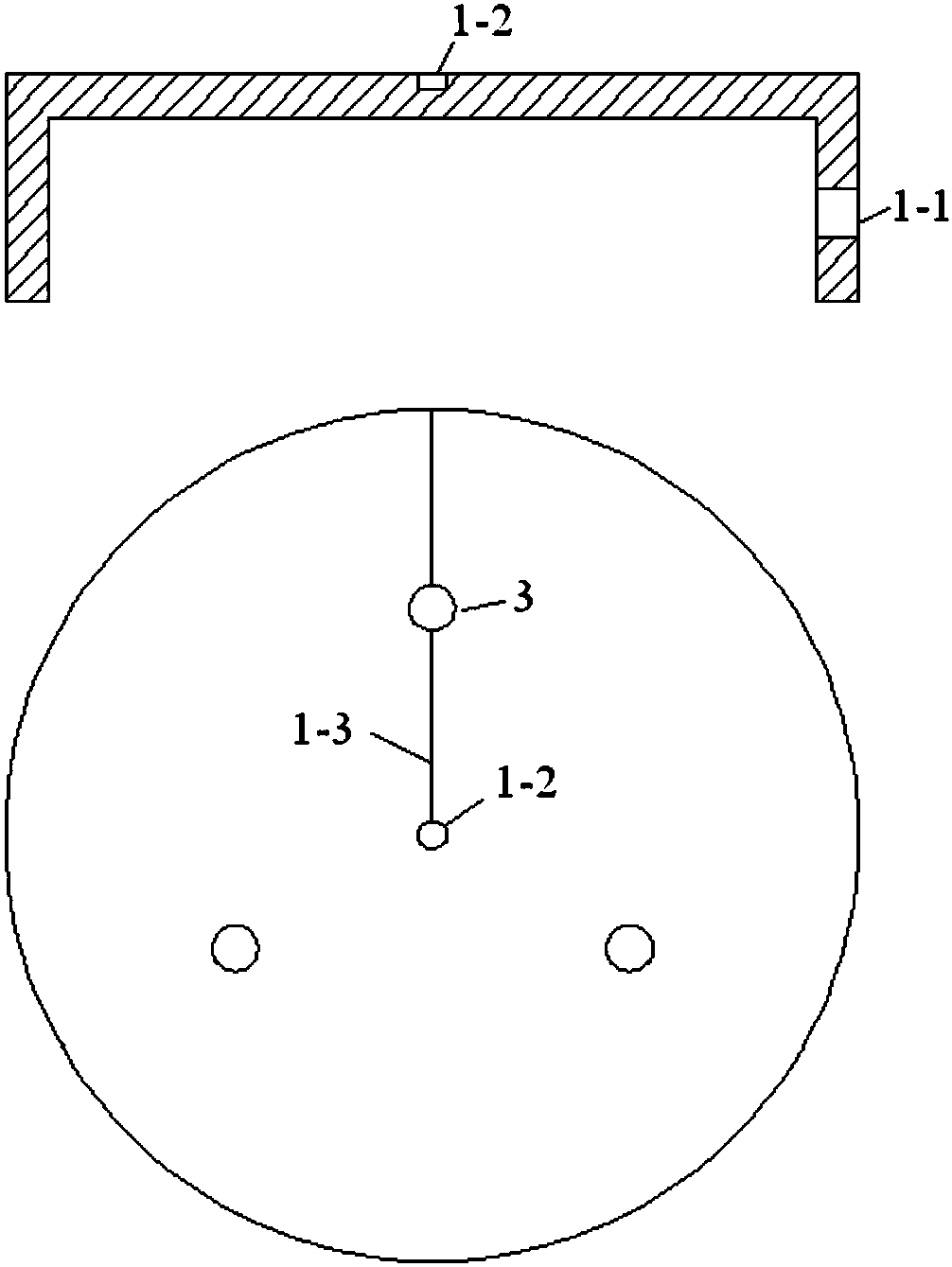

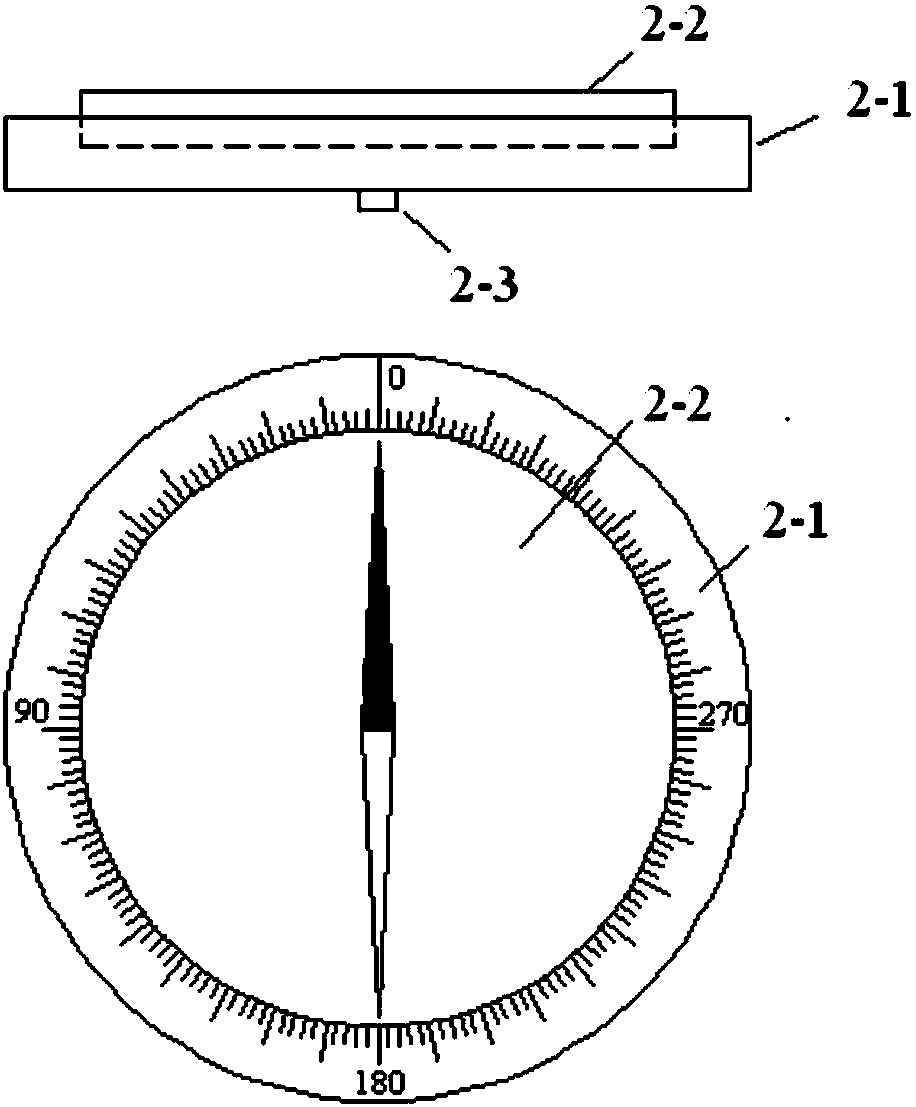

Embodiment 1

[0012] The present invention sees figure 1 , figure 2 and image 3 , including test base 1 and direction adjuster 2. The test base 1 is a cylindrical shell structure with an open lower end, which should be made of metal materials or other high-strength non-metallic materials, and a circular cable hole 1-1 is provided on the side wall for leading out signal cables; the test base Three pressure-sensitive elements 3 are installed on the upper end surface of 1; the three pressure-sensitive elements 3 are evenly distributed on a concentric circle on the upper end surface, that is, the three pressure-sensitive elements 3 are distributed in an equilateral triangle; the center of the upper end surface of the test base 1 There is a positioning groove 1-2 for installing the direction adjuster 2; the upper end surface of the test base 1 is provided with a positioning marking line 1-3, which connects the center of the upper end surface and a pressure sensitive element 3 and extends to ...

Embodiment 2

[0015] The overall composition and specific structure are the same as in Example 1. The test base 1 is made of 45# steel, with a height of 150 mm, a diameter of 300 mm, and a wall thickness of 15 mm on the side wall and the upper end surface; the pressure sensitive element 3 uses a shock wave pressure sensor. Thread the mounting holes on the test base 1, and install the shock wave pressure sensors evenly on the concentric circles with a radius of 100mm on the upper end surface of the test base 1; before the test, connect the shock wave pressure sensors on the test base 1 to the signal line, and connect the signal The wire is led out from the cable hole 1-1 and connected to the remote data acquisition instrument; the test base 1 is buried in the test site and the upper end surface is guaranteed to be horizontal; 2 Installed in the center of the test base 1, so that the 0° scale line is aligned with the positioning line 1-3 on the test base 1; adjust the angle of the device of th...

Embodiment 3

[0026] The overall composition and specific structure are the same as those in Embodiment 1-2. When using the detonation center positioning device of the present invention for testing, if the test site layout does not arrange the test device along the standard east, south, west and north directions, it can be tested according to the specific conditions of the test. The coordinate system is set in the field, when the detonation center positioning device of the present invention is installed, the positioning marking line 1-3 can be aligned with the indication direction of a coordinate axis in the coordinate system, and the detonation center azimuth angle measured by the detonation center positioning device of the present invention is the coordinate The relative azimuth under the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com