Welding wire for ultralow-temperature steel

An ultra-low temperature, welding wire technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as affecting welding quality, reducing welding arc stability, and lack of fusion. Excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

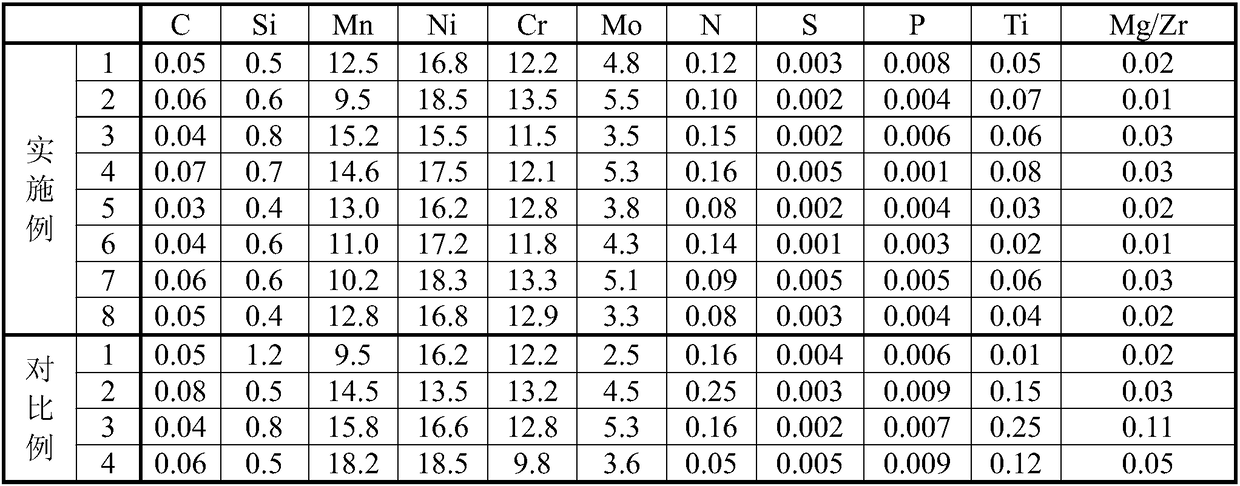

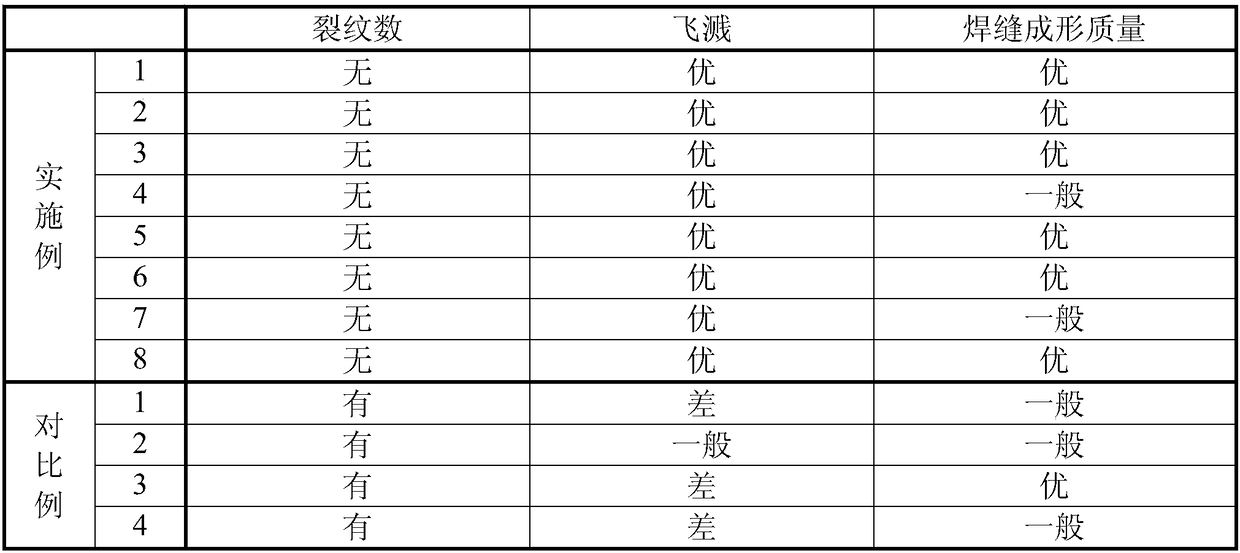

[0037] Carry out the welding test, start from the root for 1 pass welding, welding current 230-250A, welding voltage 11-13V, welding speed 7-9cm / min, and then conduct quality inspection on the welding part.

[0038] The results are shown in Table 2.

Embodiment 3-4

[0040] Carry out the welding test, start from the root for 5 times of welding, welding current 230-250A, welding voltage 11-13V, welding speed 7-9cm / min, and then conduct quality inspection on the welding part.

[0041] The results are shown in Table 2.

Embodiment 5-8

[0043] Carry out the welding test, starting from the root until it is fully welded, the welding current is 190-210A, the welding voltage is 11-13V, the welding speed is 6-9cm / min, and then the quality inspection of the welding part is carried out.

[0044] The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com