Reinforced-type wooden structure anti-bending heat insulation wall plate

A technology for thermal insulation wall panels and wood structures, applied in building components, building structures, climate change adaptation, etc., can solve problems such as swallowing up fertile fields and land, reduce earthquake response, absorb less seismic force, and reduce resource and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

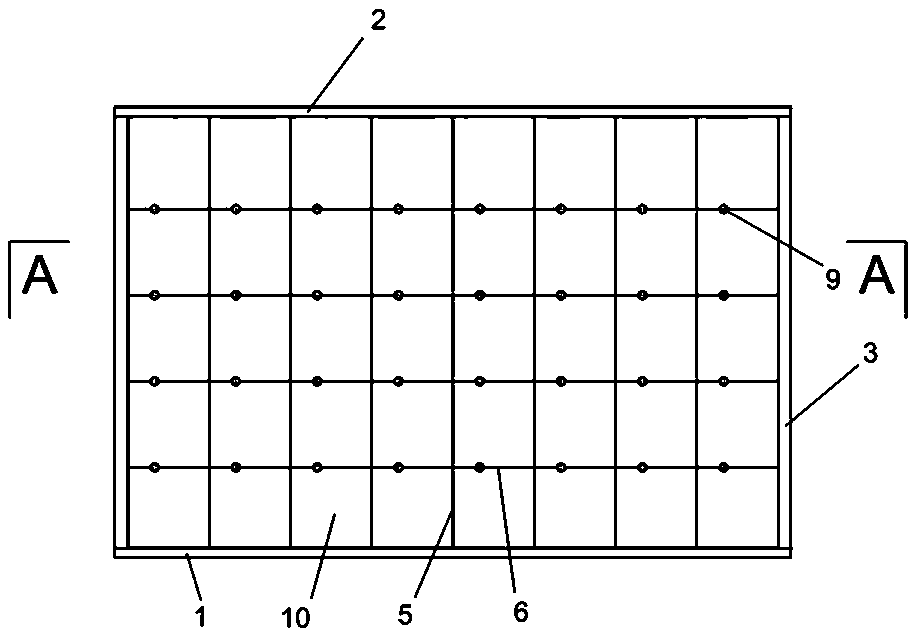

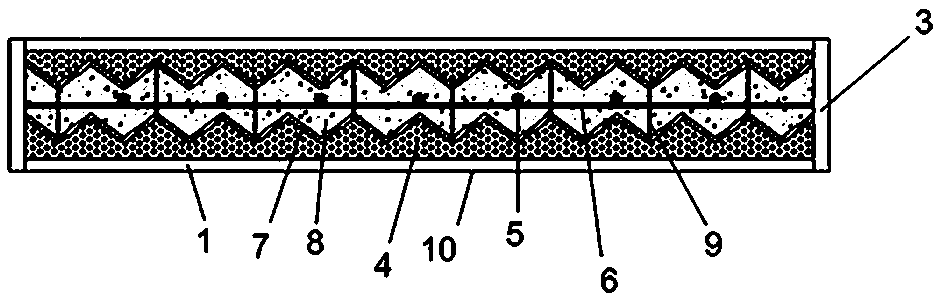

[0020] like Figure 1~Figure 2 As shown, a reinforced wood structure anti-folding thermal insulation wall panel comprises a wooden bottom plate (1), a wooden top plate (2), a wooden side plate (3), a thermal insulation filling material (4), and an inner vertical reinforcing rib (5) , inner transverse reinforcement (6), toothed anti-bending energy-dissipating steel plate (7), filled fiber concrete (8) and wall panel layer (10); The wooden top board (2) and the wooden bottom board (1), the two side ends between the wooden top board (2) and the wooden bottom board (1) are respectively wooden side boards (3), wooden bottom board (1), wooden top board ( 2) The wooden side board (3) and the wall panel layer (10) are surrounded by a wooden outer frame, and the left and right ends of the wooden bottom board (1) and the wooden top board (2) extend to the outer edge of the wooden side board (3); Inside the wooden frame, a double-layer tooth-shaped energy-dissipation resistance steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com