Detection system and method for fluid nonmetal particle concentration

A technology of non-metallic particles and metal particles, which is applied in particle suspension analysis, measuring device, suspension and porous material analysis, etc. It can solve problems such as difficult to achieve accurate detection, single fixed detection plane, and affecting the detection accuracy of particle concentration in fluids, etc. , to achieve the effect of improving accuracy and fully detecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] Embodiment 1 (a kind of detection system of non-metal particle concentration in fluid)

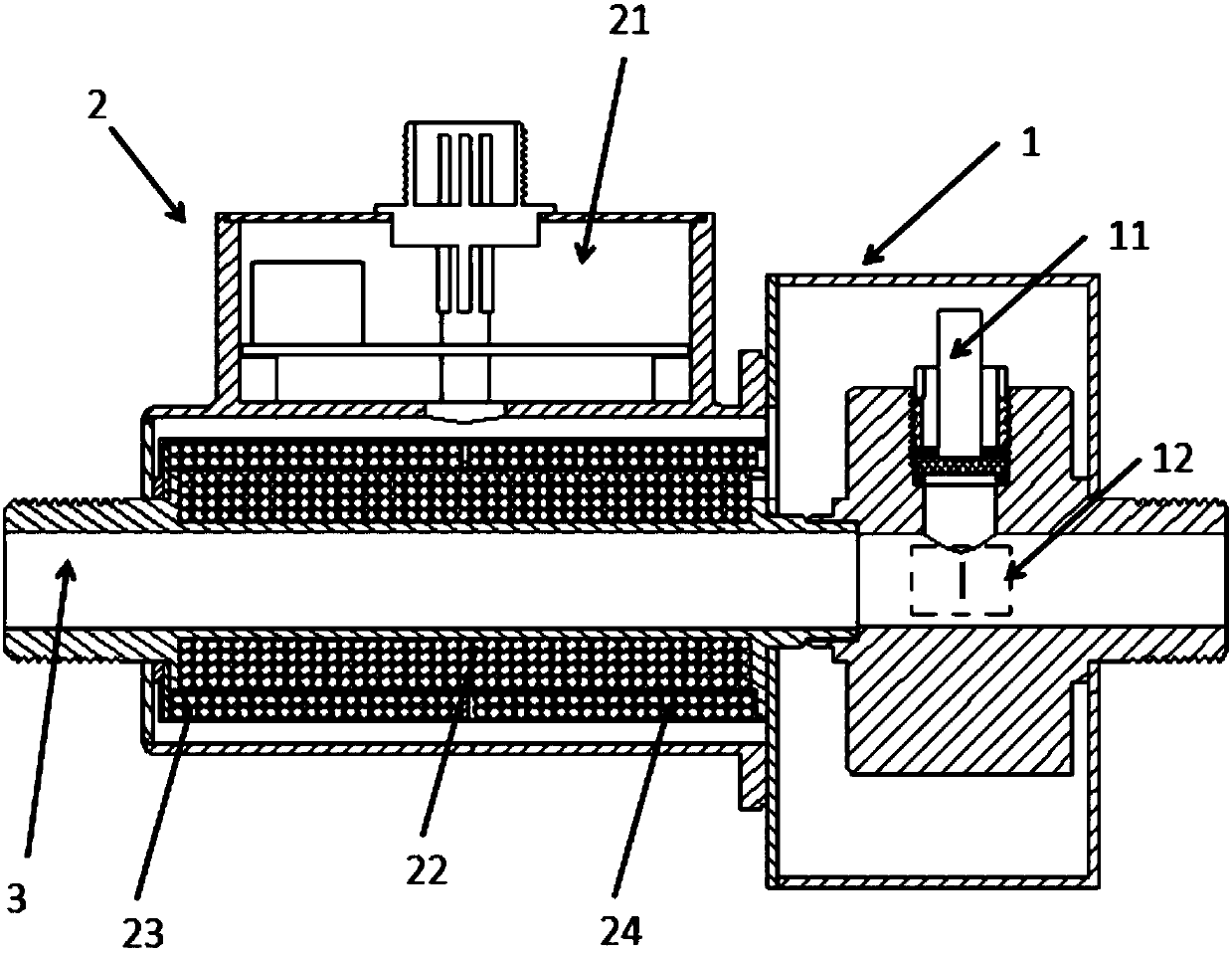

[0136] As shown in Figure 1 (a), it is a schematic structural view of a preferred embodiment of a detection system for non-metallic particles in a fluid of the present invention. The detection system includes a particle shape detection device 1 and a metal particle detection device 2 And the detection pipeline 3, the particle shape detection device and the metal particle detection device are connected to each other and wound on the detection pipeline;

[0137] As shown in Figure 1(a) and Figure 1(b), the particle shape detection device includes: a laser tube 11 for outputting an incident light beam; a scattering detector 12 for detecting a fluid outgoing light beam;

[0138] The metal particle detection device includes a signal detection system 21, an excitation coil 22, and two induction coils (respectively a first induction coil 23 and a second induction coil 24), and the excitati...

Embodiment 2

[0143] Embodiment 2 (a metal particle detection device in the detection system of the concentration of non-metallic particles in a fluid)

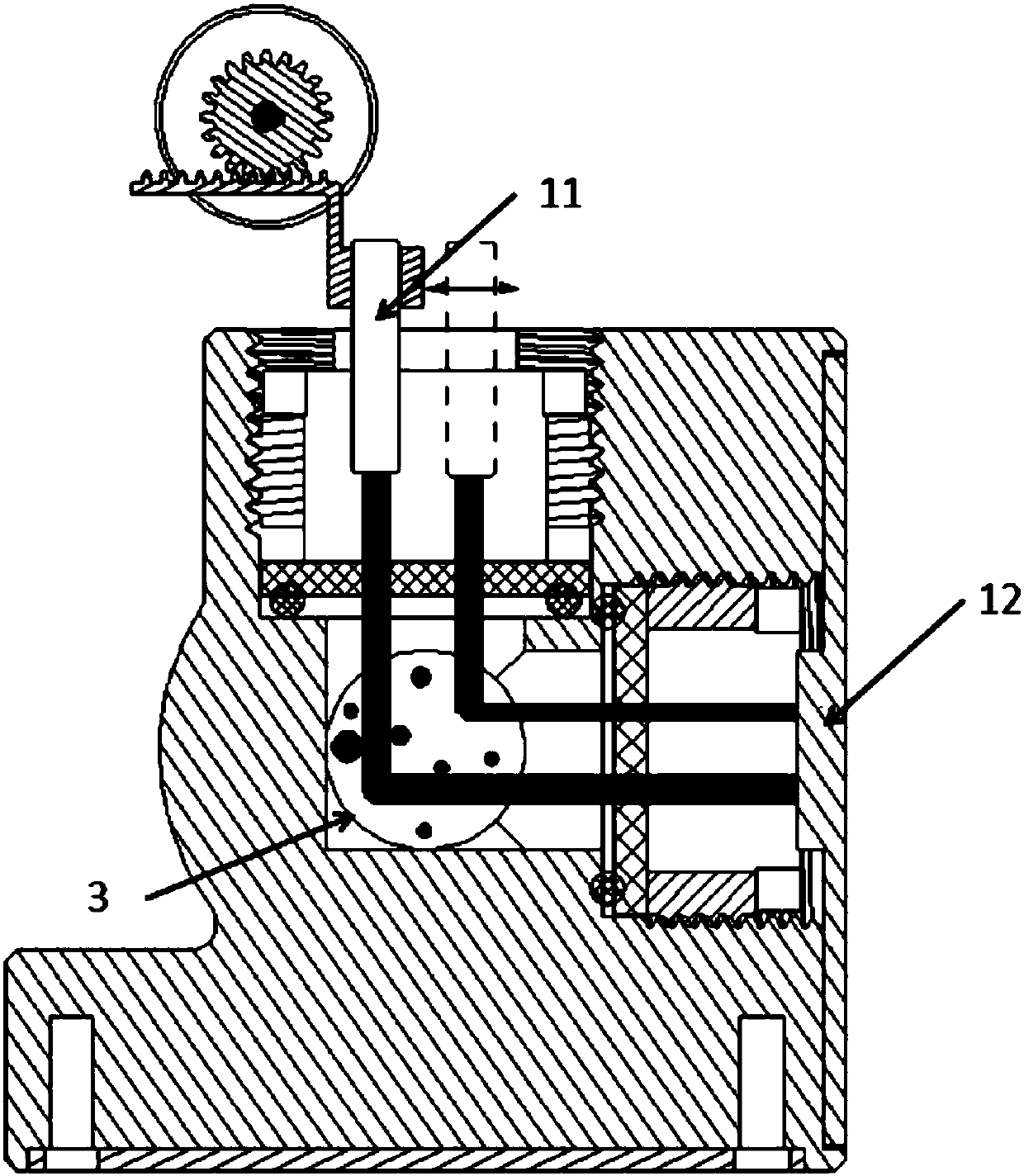

[0144] Such as figure 2 Shown is a schematic cross-sectional structure diagram of the first preferred embodiment of the metal particle detection device in the system of the present invention;

[0145] The detection device includes a signal detection system 21, an excitation coil 22, and two induction coils (respectively a first induction coil 23 and a second induction coil 24), the excitation coil is connected with the signal processing system and wound on On the detection pipeline 3; the induction coils are all connected to the signal processing system, and wound on the excitation coils sequentially and oppositely to each other.

[0146] The above is one of the preferred implementations of the technical solution. This basic implementation has the following beneficial effects:

[0147] (1) The setting method of the excitation coil and t...

Embodiment 3

[0154] Embodiment 3 (a metal particle detection device in the detection system of the concentration of non-metallic particles in a fluid)

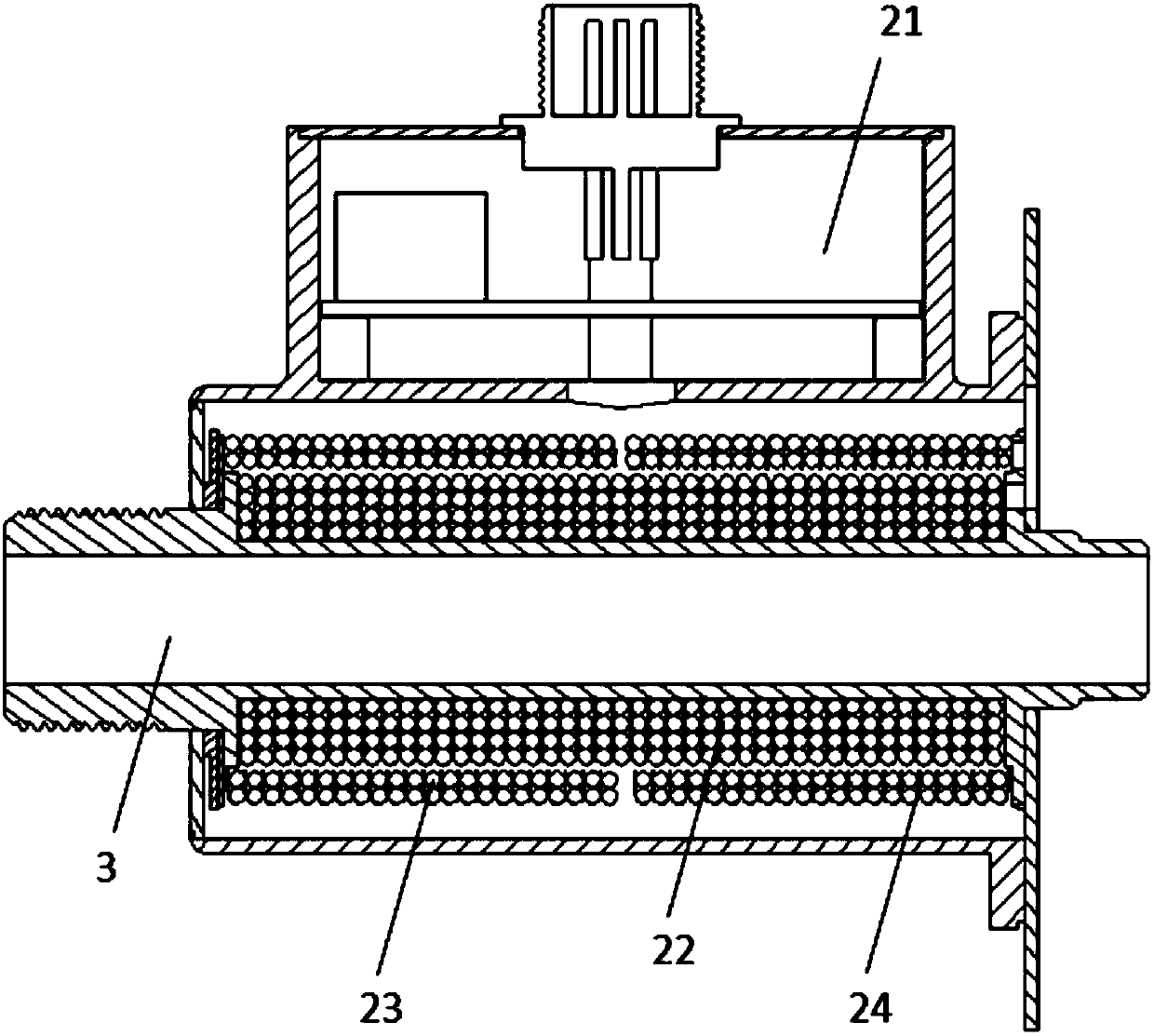

[0155] Such as image 3 Shown is a schematic cross-sectional structure diagram of the second preferred embodiment of the metal particle detection device in the detection system of the present invention; the difference between this embodiment and the above-mentioned embodiment 1 is that: Figure 4 As shown, a spacer sleeve 25 is also arranged between the excitation coil and the induction coil in the detection device, that is, the excitation coil is covered with a spacer sleeve, and the induction coil is wound on the on the spacer sleeve. And, a shielding ring 26 is provided outside the induction coil.

[0156] The above two technical solutions can be implemented together, or only one can be implemented, depending on the needs. In this embodiment, both solutions are implemented, that is, a spacer ring sleeve and a shielding ring are prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com