A kind of decorative fair-faced concrete electric pre-embedded box and its construction method

A technology of electrical pre-embedded boxes and fair-faced concrete, which is applied in the treatment of electrical components, building materials, construction, etc., can solve the problems of facing clear-faced concrete pollution and time-consuming, avoid repairs and chisels, simplify the construction process, The effect of optimizing the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

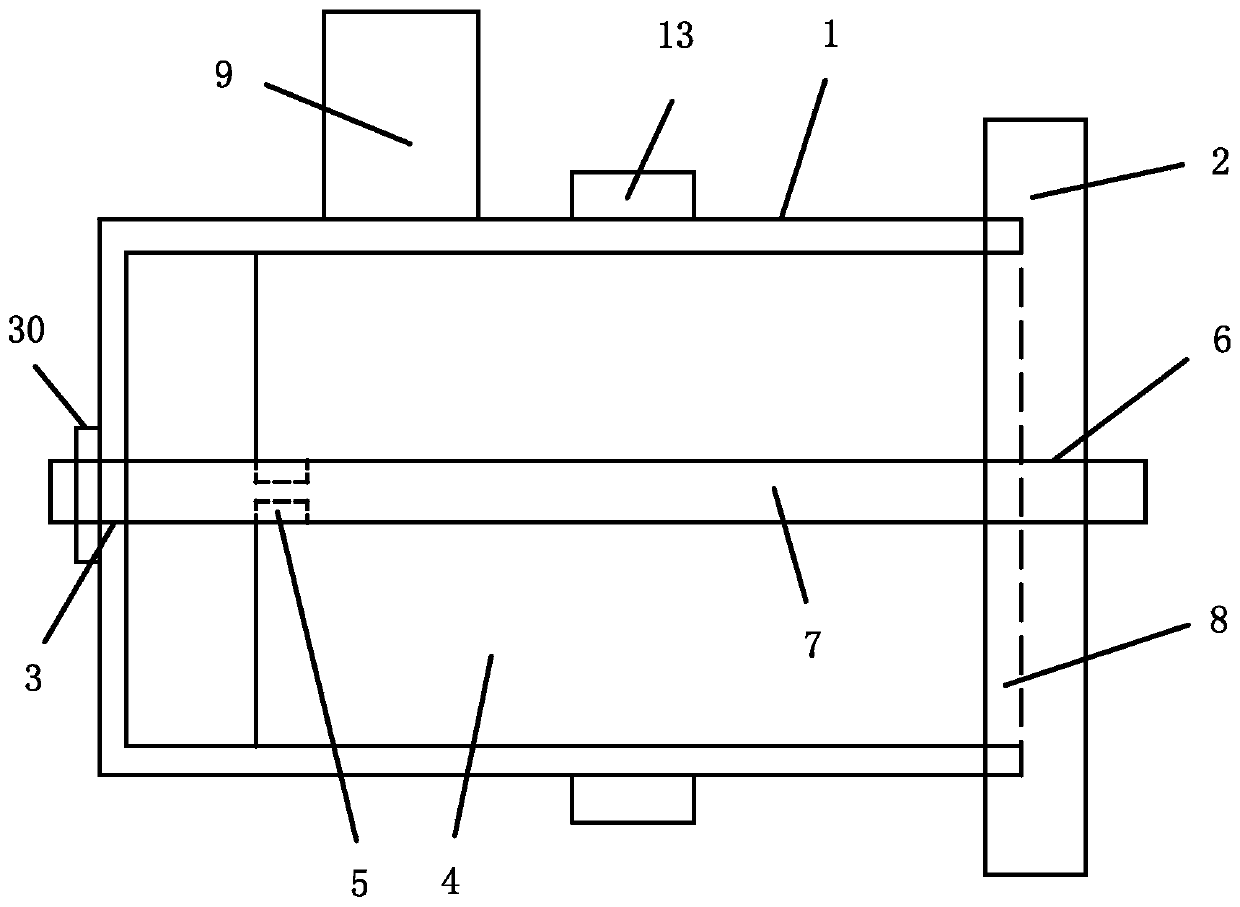

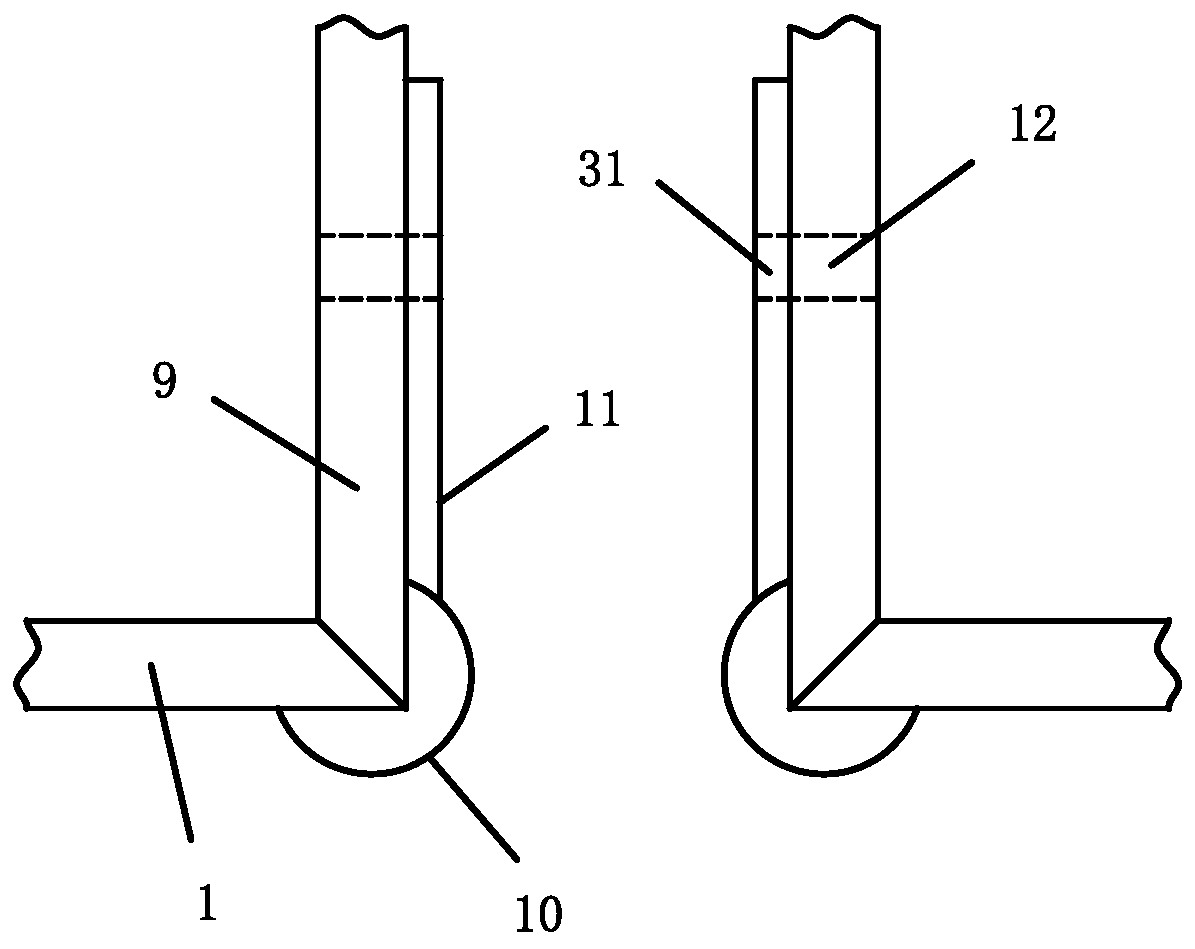

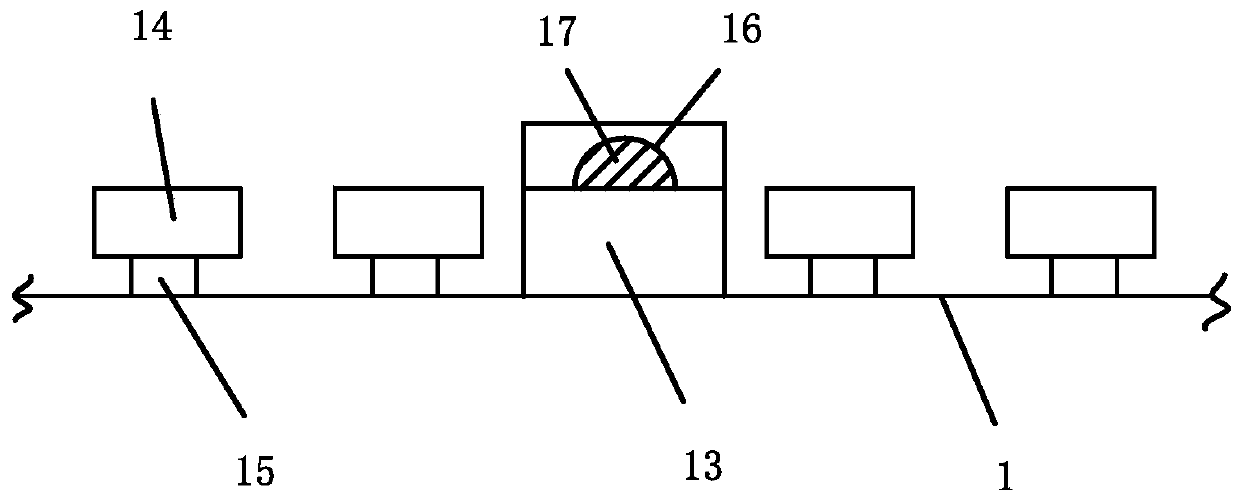

[0026] refer to Figure 1-5 A specific embodiment of the present invention includes a box body 1 and a template 2, the box body 1 is provided with a conduit connector 9, the bottom of the box body 1 is provided with a first through hole 3, and the bottom surface of the template 2 is symmetrically provided with two support plates 4. A notch 5 is provided at the bottom of the support plate 4, and a second through hole 6 is provided in the center of the template 2. The fixing bolt 7 passes through the second through hole 6 and the first through hole 3 and connects with the nut 30 to fix the template 2 in the box. On the body 1, the fixing bolt 7 is in interference fit with the notch 5. When the fixing bolt 7 is inserted into the box body 1, the fixing bolt 7 pushes the support plate 4 and the inner wall of the box body 1 to be pressed against each other; the edge of the bottom surface of the template 2 is provided with The groove 8, the top edge of the box body 1 and the groove 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com