A kind of preparation method and application of metal organic framework that catalyzes carbon dioxide to epoxy carbonate

A technology of epoxy carbonate and organic framework, which is applied in chemical instruments and methods, organic chemistry, physical/chemical process catalysts, etc., and can solve problems such as high cost, immature technology, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

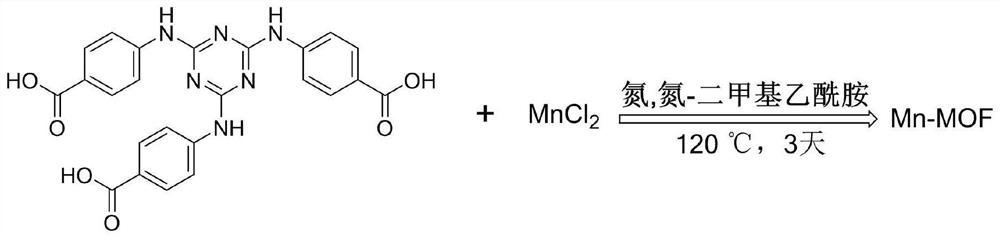

[0024] A kind of preparation method of manganese metal organic framework material, synthetic route is as follows figure 1 shown.

[0025] Take 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine, dissolve manganese chloride in N,N-dimethylacetamide, add distilled water, place in poly The reaction was carried out at 120°C for 72 hours in a tetrafluoroethylene-lined reactor, and the temperature was slowly lowered to room temperature at 5°C / h to obtain a colorless rod-shaped crystal "Mn-MOF" with a yield of 83%. The ratio of raw materials 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine, manganese chloride, nitrogen, nitrogen-dimethylacetamide and distilled water is 73.0mg:12.6mg :3mL:0.75mL, the volume of the polytetrafluoroethylene lining is 25mL.

[0026] The invention relates to a heterogeneous catalyst system. The preparation of the catalyst is an important index for evaluating the catalyst. The preparation method of the catalyst is simple, low in cost and easy for industri...

Embodiment 2

[0032] An application of the Mn-MOF prepared in Example 1 in catalyzing carbon dioxide as epoxy carbonate, the steps are as follows:

[0033] 1) In the glove box, weigh the Mn-MOF catalyst prepared in Example 1 and the cocatalyst tetrabutylammonium bromide in a Schlenk bottle. The dosage ratio of Mn-MOF and tetrabutylammonium bromide is 100mg:3.6mmol.

[0034] 2) Take the Schlenk bottle out of the glove box, connect the branch pipe of the Schlenk bottle to a vacuum line and degas it, and then connect a 1 atm carbon dioxide balloon to the branch pipe to fill the Schlenk bottle with carbon dioxide gas.

[0035] 3) Inject 5.0 mmol each of styrene oxide, 2-(chloromethyl)oxirane, 3-phenoxy-1,2-propylene oxide, 3-(1-naphthyloxy)-1 , 2-propylene oxide and benzyl glycidyl ether into the Schlenk bottle, put the Schlenk bottle in an oil bath at 60°C, and react for 24h.

[0036] 3) After the reaction is completed, the crude epoxy carbonate is obtained, and then the silica gel column is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com