Automatic packaging production line for industrial explosives

A technology for automatic packaging and industrial explosives, which is applied in the field of explosive packaging production, and can solve problems such as potential safety hazards, the danger of explosives, and damage to explosives

Inactive Publication Date: 2018-05-18

HENAN ZHIJIN NETWORK TECH CO LTD

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When explosives explode, they can release a large amount of heat energy and generate high-temperature and high-pressure gas, which can damage, throw, and compress surrounding materials. Explosives often need to be packaged during the production process, and packaging is also a procedure that requires great attention. There are factors that cause the explosives to be unstable due to excessive pressure, such as the automatic packaging production line for industrial explosives with application number 201610934584.9, in which the explosives are removed by means of a push rod, and the process of pushing and falling the explosives will be very safe Hidden dangers may cause damage to explosives or even the danger of explosives. It is necessary to improve it. For this reason, we propose an automatic packaging production line for industrial explosives

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

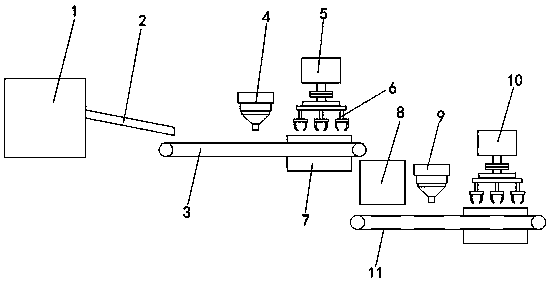

The invention discloses an automatic packaging production line for industrial explosives. The automatic packaging production line comprises a cartridge packaging mechanism located at the start part ofthe production line, wherein a discharge plate which is inclined downwards is arranged on one side of the cartridge packaging mechanism; a cartridge conveying mechanism is arranged below one side, away from the cartridge packaging mechanism, of the discharge plate; a first image information collector and a first drive motor are arranged on the upper side of the cartridge conveying mechanism in sequence; the first image information collector is located between the discharge plate and the first drive motor; an output shaft of the first drive motor is downward and is connected with a fixed platethrough a coupling; multiple manipulators are arranged on the lower surface of the fixed plate at equal intervals in a surrounding manner. According to the automatic packaging production line for theindustrial explosives, unqualified products are grabbed by the manipulators, grabbing strength can be controlled, the unqualified explosives can be placed very well, compared with a pushing manner inthe background art, the probability of danger occurrence is greatly reduced, and the production line has good popularization value.

Description

technical field [0001] The invention relates to the technical field of explosive packaging production, in particular to an automatic packaging production line for industrial explosives. Background technique [0002] Explosive material is a substance that can burn violently (that is, explode) in a very short period of time. It is a substance that explodes by its own energy under the action of a certain amount of external energy. Under normal circumstances, the chemical and physical properties of explosives are stable, but regardless of whether the environment is sealed or not, the amount of charge, or even in the case of zero oxygen supply from the outside world, as long as there is strong energy (provided by the detonator) to stimulate, the explosives will be released to the outside world. Carry out stable detonation type work. When explosives explode, they can release a large amount of heat energy and generate high-temperature and high-pressure gas, which can damage, throw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C06B21/00B65B35/24B65B65/00

CPCC06B21/00B65B35/24B65B65/003

Inventor 尹传喜

Owner HENAN ZHIJIN NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com