Fork of forklift for textile goods

A forklift and fork technology, which is applied in the field of forklift forks for textile products, can solve the problems of extrusion deformation, damage, and inability to guarantee product quality of silk fabrics, and achieve the effects of avoiding extrusion deformation, alleviating bumps, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

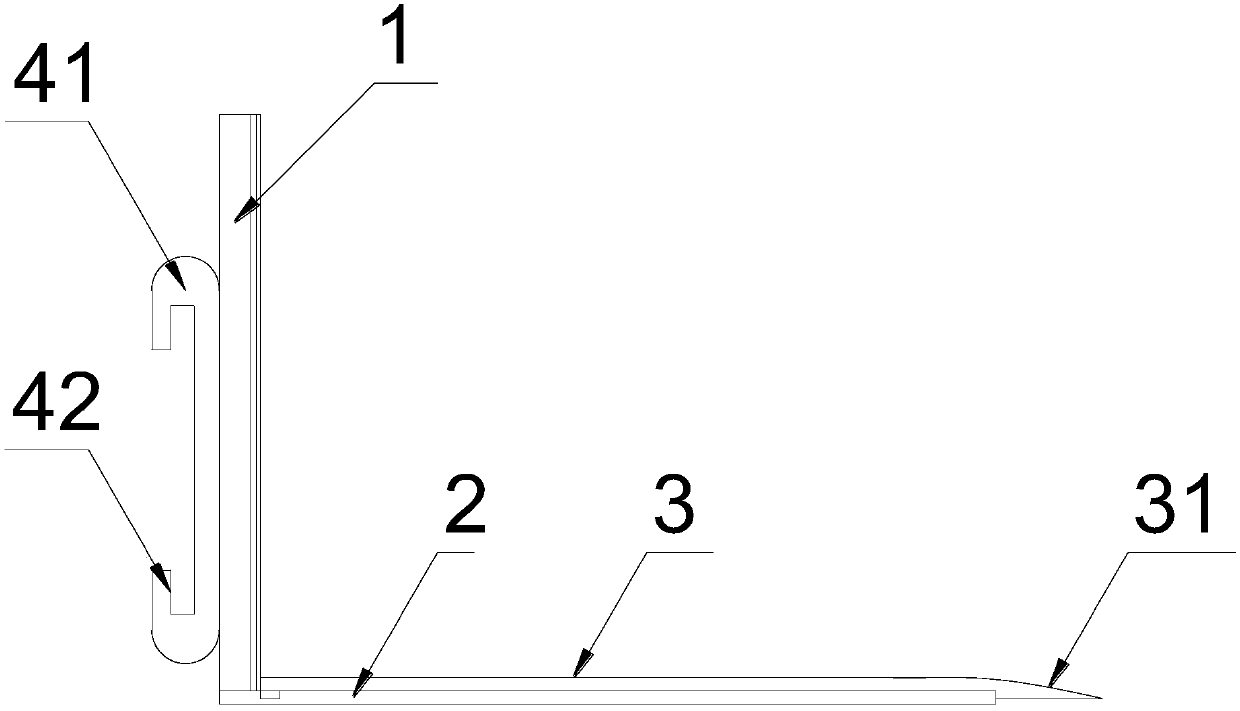

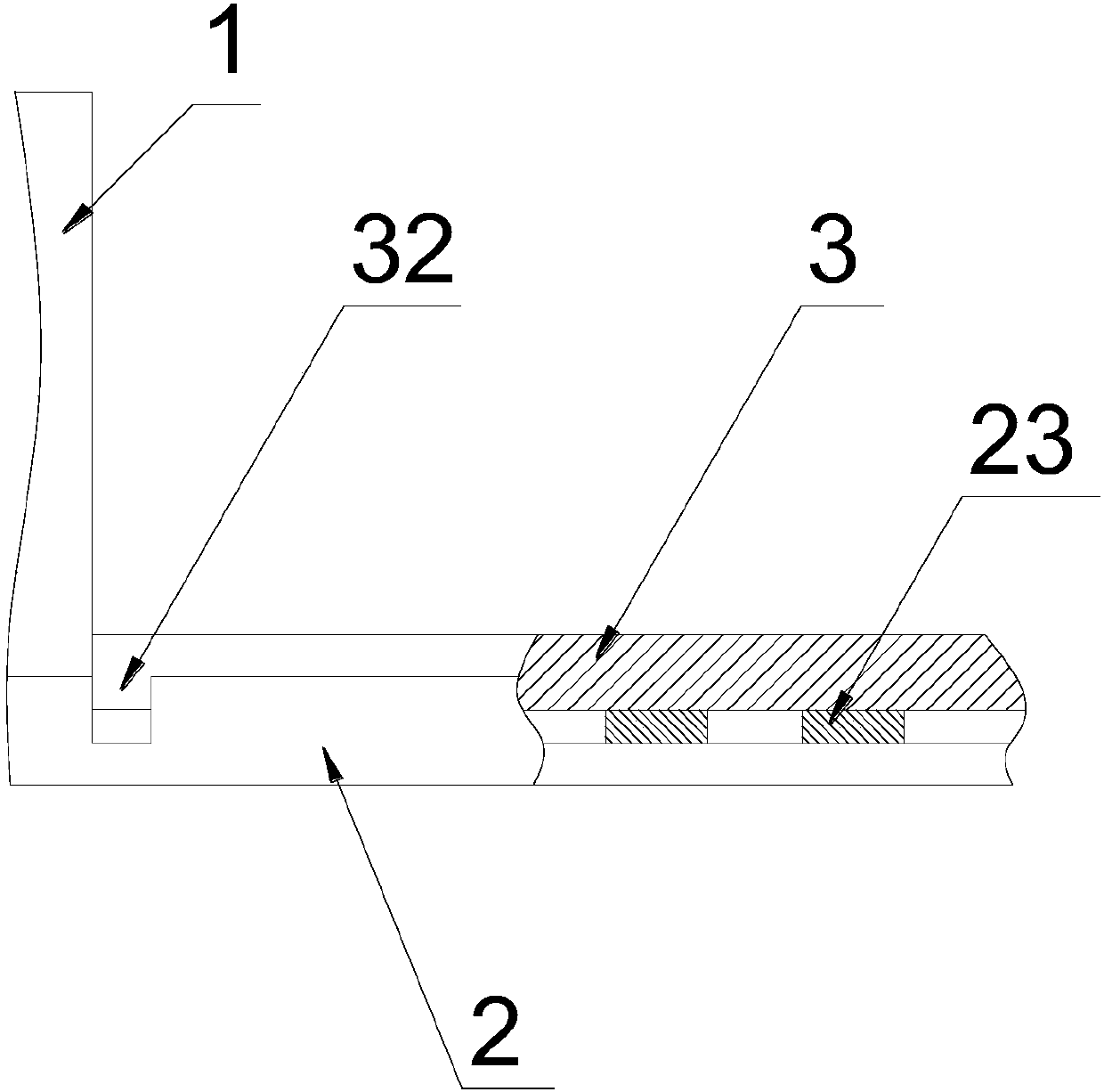

[0020] Such as Figure 1-6 as shown, figure 1 It is a structural schematic diagram of a forklift fork for textile articles proposed by the present invention, figure 2 It is a structural schematic diagram of the vertical plate in the forklift fork for textile articles proposed by the present invention, image 3 It is a schematic diagram of the connection between the horizontal plate and the load-bearing plate of the forklift fork for textiles proposed by the present invention, Figure 4 It is a cross-sectional view of the transverse plate in the forklift fork for textile articles proposed by the present invention, Figure 5 It is a structural schematic diagram of the horizontal plate in the forklift fork for textile articles proposed by the present invention, Figure 6 It is a structural schematic diagram of the part of the load-bearing plate in the fork of the forklift for textile articles proposed by the present invention.

[0021] refer to Figure 1-6 , a forklift fork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com