A high-efficiency machine tool for logistics operations

A high-efficiency and logistics technology, applied in the field of machinery, can solve the problems of occupying external space, lengthening the overall length of the carriage, inconvenient operation, etc., and achieve the effect of increasing the length of the carriage, reasonable structural design and diversified movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0020] For convenience of description, figure 1 The left side is the front, and the right side is the back.

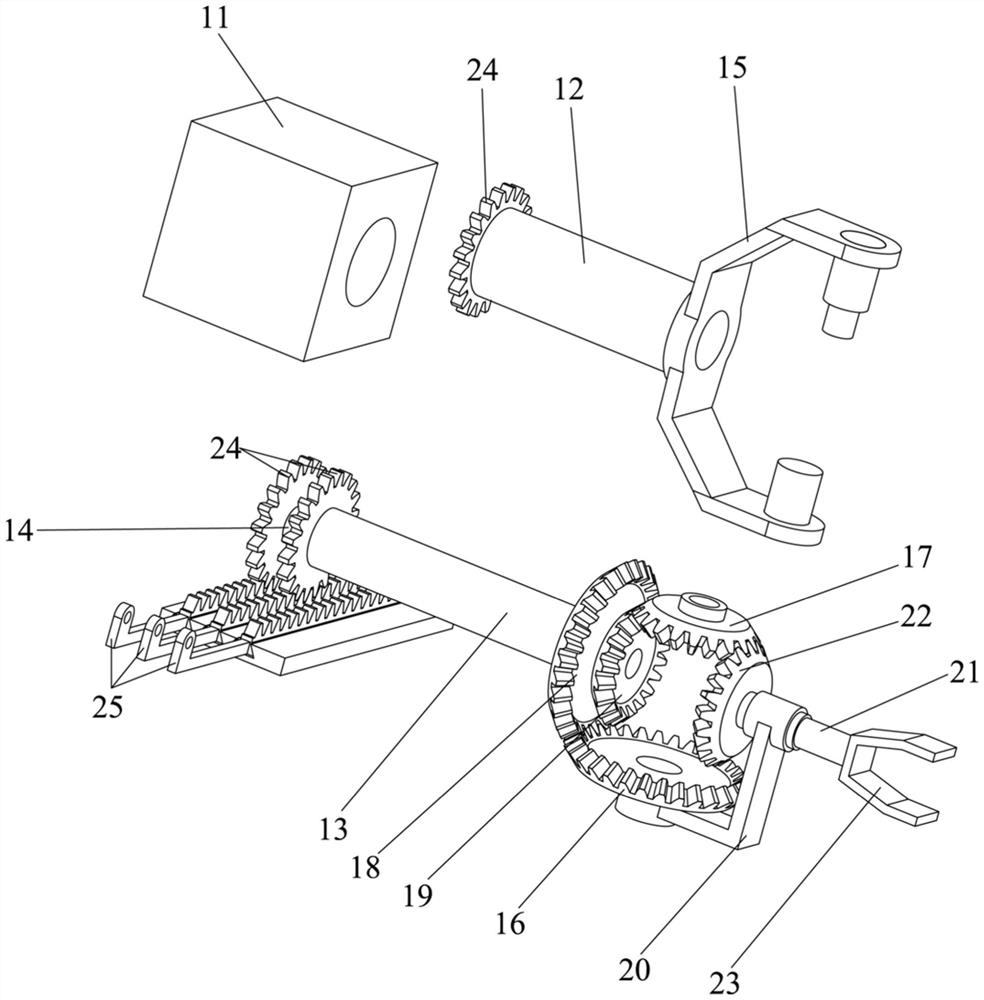

[0021] like Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a high-efficiency machine tool for logistics operations, including a carriage 100, the carriage 100 is provided with a manipulator device 10, and the manipulator device 10 includes a rotating shaft mounting seat 11 fixed on the carriage 100. The first rotating shaft 12, the second rotating shaft 13, and the third rotating shaft 14 are sequentially rotated and socketed on the rotating shaft mounting base 11 from the outside to the inside, that is, the first rotating shaft 12, the second rotating shaft 13, and the third rotating shaft 14 are arranged coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com