Novel lightweight environment-friendly pedal of scaffold for building, and production process thereof

A technology of scaffolding and stepping on pedals, which is applied to the accessories of scaffolding, buildings, building structures, etc., which can solve the problems of short replacement cycle, increased production cost, and short service life, so as to reduce material costs, high degree of automation, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments. The illustrative embodiments and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

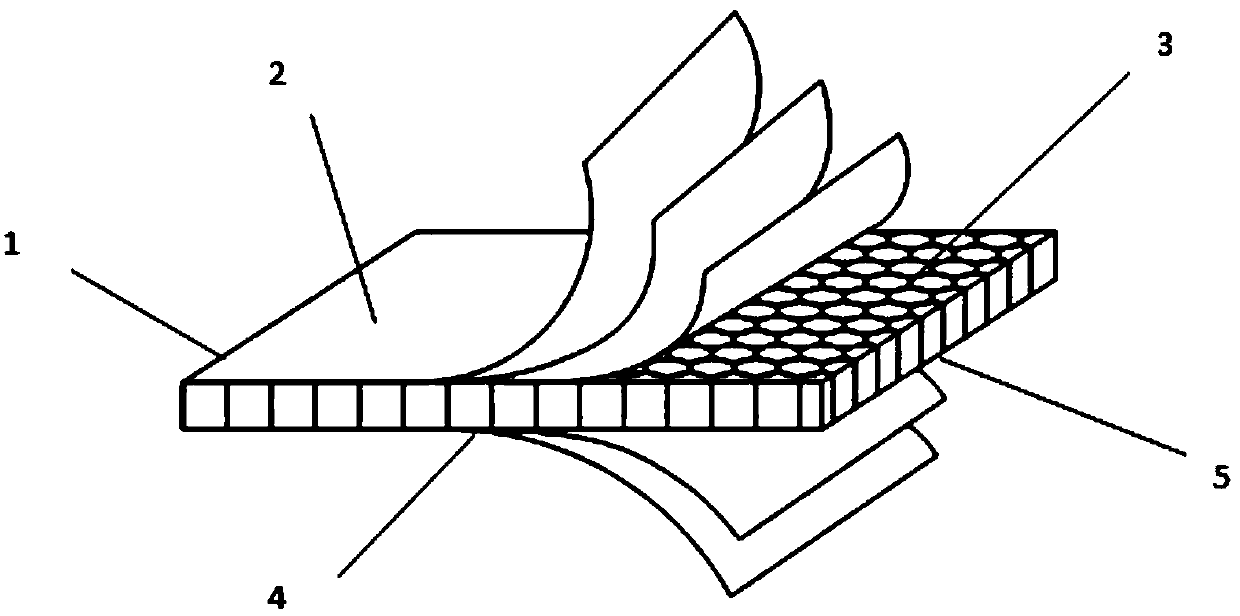

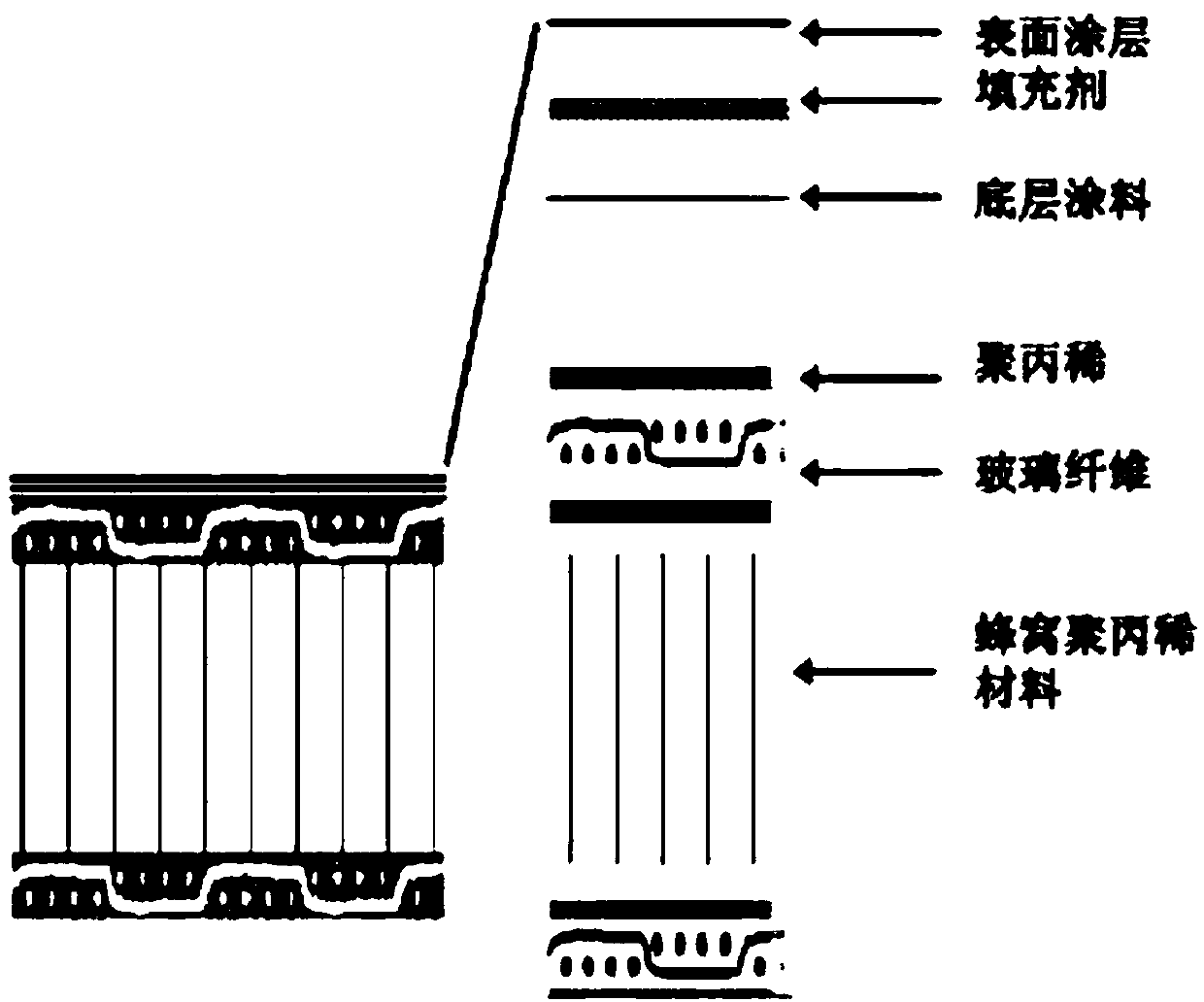

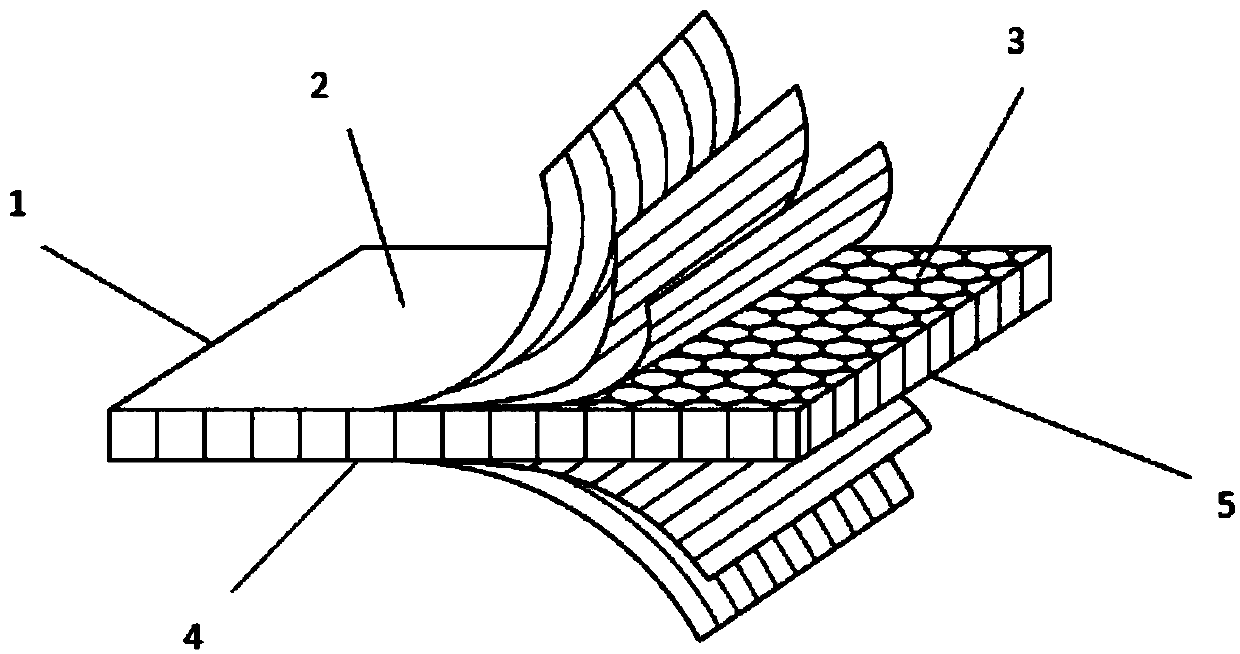

[0037] Such as Figure 1-6 As shown, a new type of lightweight environmental protection building scaffolding pedal and production process, the structure includes: plate 1, top skin 2, polypropylene honeycomb core 3, bottom skin 4, finished plate 5; plate 1 is divided into three-layer sandwich structure , The upper skin 2 and the lower skin 4 are both composited by a multi-layer continuous glass fiber polypropylene reinforced unidirectional prepreg tape, the middle is a pure polypropylene honeycomb core 3, of which the continuous glass fiber polypropylene reinforced unidirectional prepreg tape is used Polypropylene and continuous glass fiber are composited as raw materials. The finished sheet 5 is hot-melt bonded w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com