Tin welding machine

A technology of soldering machine and soldering head, applied in welding positions, tin feeding devices, welding equipment, etc., can solve the problems of low production efficiency and unstable welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

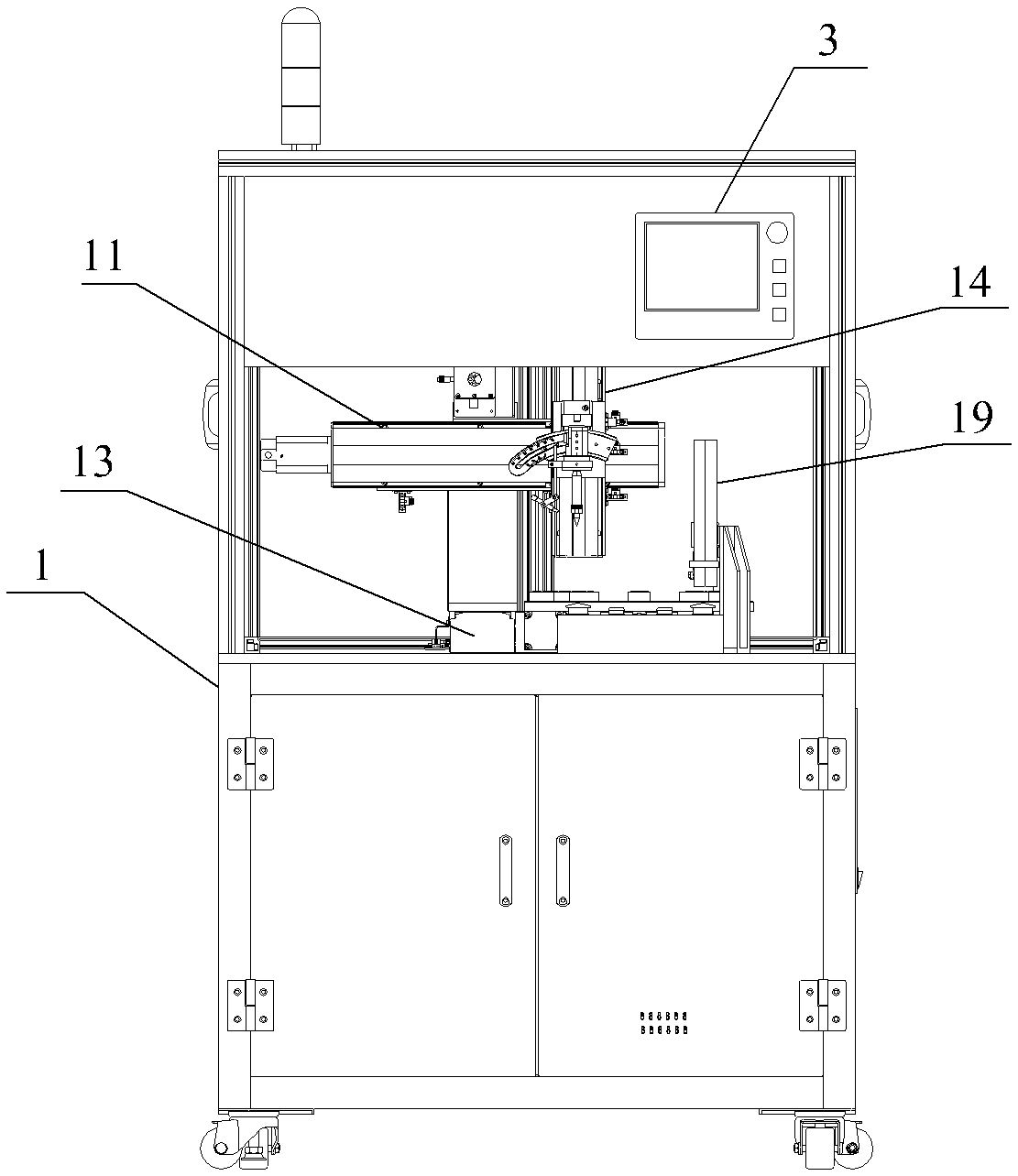

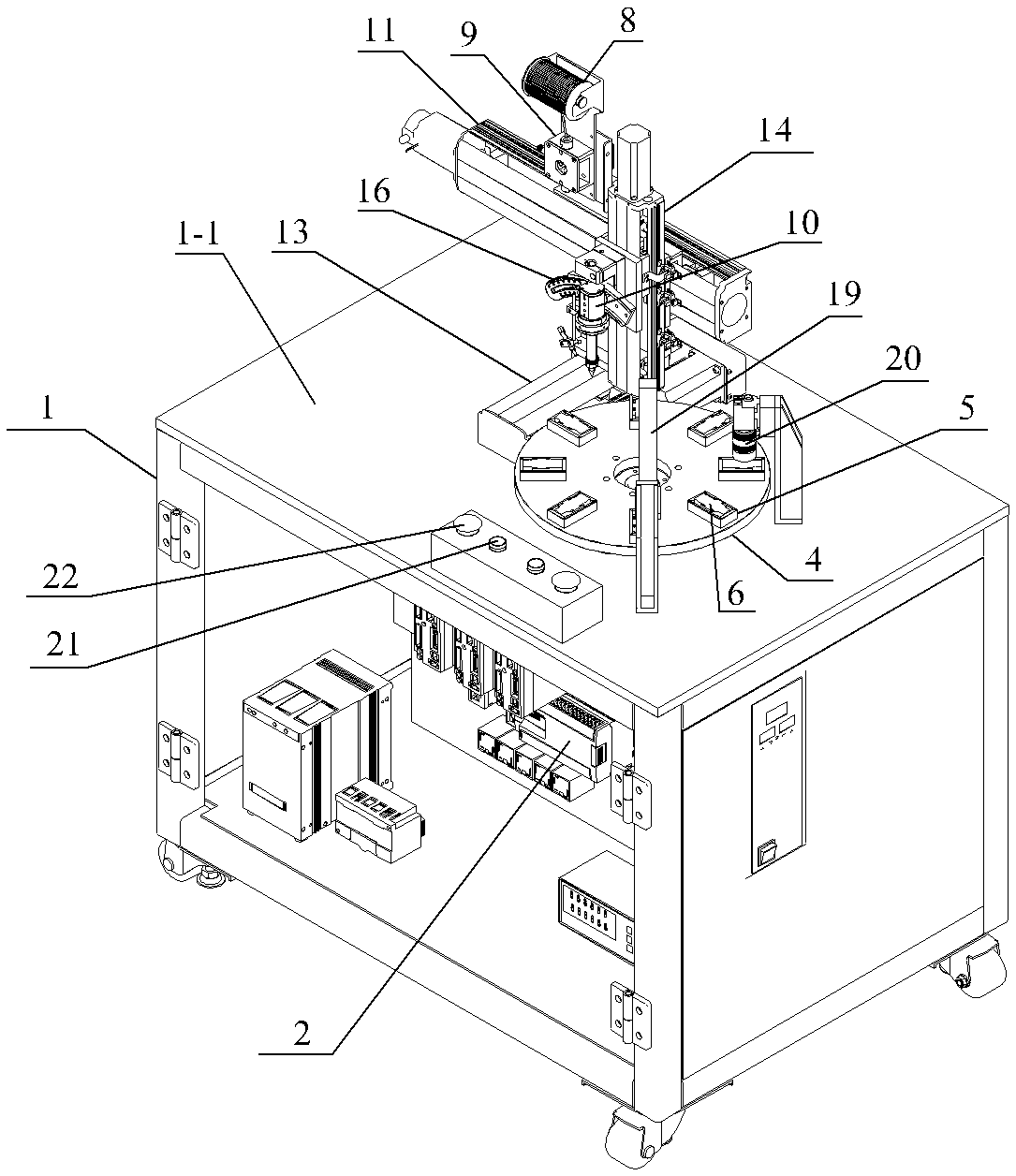

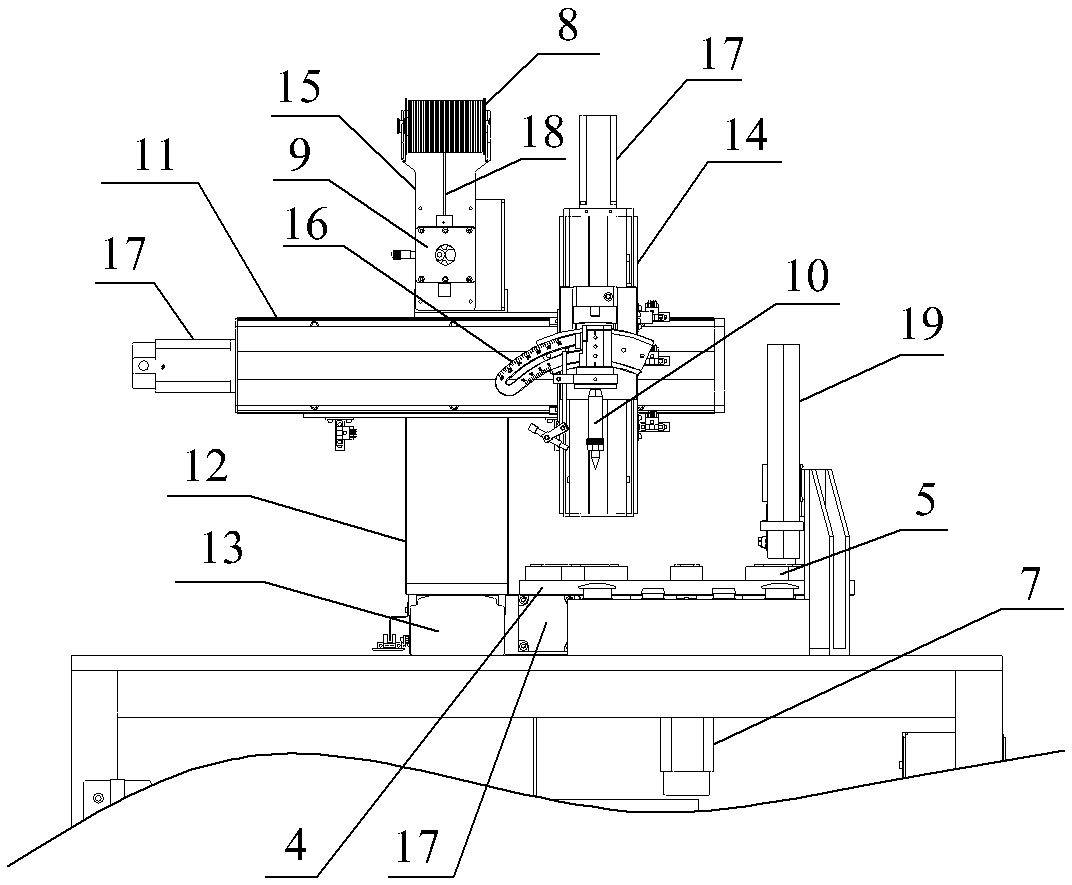

[0020] See Figure 1 to Figure 3 , a kind of soldering machine of the present invention, it comprises frame 1 and is installed in the PLC controller 2 in frame 1, touch screen 3 is installed on frame 1, touch screen 3 is electrically connected with PLC controller 2; There is a horizontal workbench 1-1, on which a solder head support, a turntable 4, an image recognition detection device and a marking device are respectively installed; eight product carriers 5 are evenly distributed along the circumference of the turntable 4, The product carrier 5 is provided with a workpiece groove for positioning the workpiece 6 to be welded. The turntable 4 is driven by the hollow divider to perform index rotation in the horizontal direction. The servo motor 7 of the hollow divider is electrically connected to the PLC controller 2 . The tin wire reel 8, the wire feeder 9 and the solder head 10 are respectively installed on the solder head support. The solder head support includes an X-axis mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com