Spraying device of dishwasher

A technology for spraying devices and dishwashers, which is applied to household cleaning devices, tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, etc. Water and other problems, to achieve the effect of high cleaning efficiency and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

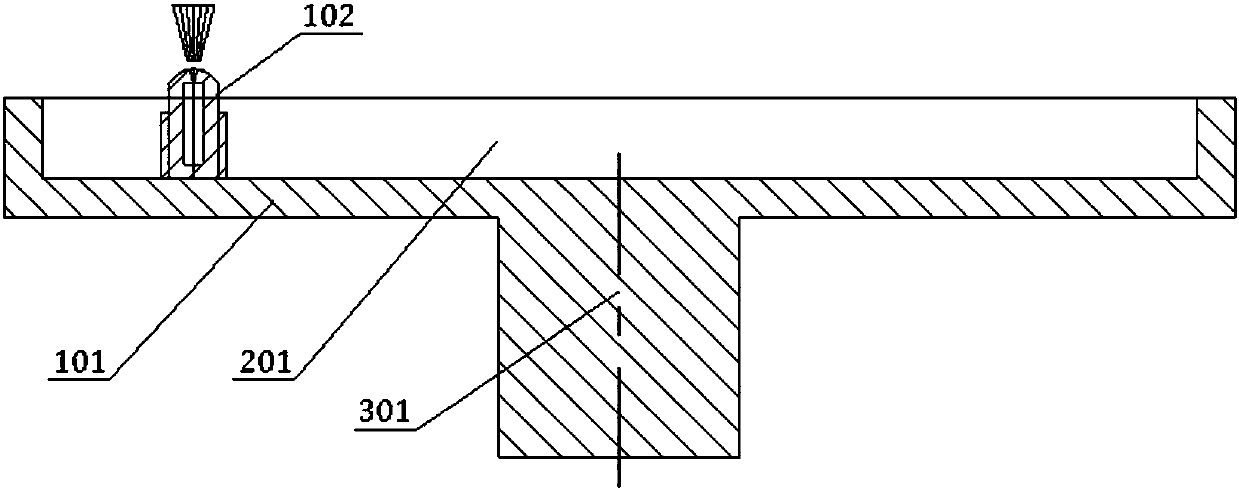

[0017] Such as figure 1 As shown, this embodiment includes a nozzle holder 101 and a high-pressure nozzle 102, wherein the nozzle holder 101 can be rotated around its own rotation axis 301, the nozzle holder 101 is provided with a linear displacement mechanism, and the high-pressure nozzle 102 is arranged on the linear displacement mechanism to reciprocate and translate.

[0018] Preferably, the linear displacement mechanism adopts a linear guide rail 201 .

[0019] Preferably, the number of the high-pressure spray head 102 is one.

[0020] The high-pressure spray head 102 is installed obliquely or vertically on the head seat 101; the high-pressure spray head 102 can be replaced, and different shapes and sizes can be selected according to needs.

[0021] In this embodiment, the high-pressure nozzle 102 reciprocates on the linear guide rail 201 at a speed V, and the high-pressure water ejected by the high-pressure nozzle 102 will form a long water column with a certain width; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com