Control method and control device for grass mower, and grass mower using same

A technology of a control device and a control method, which is applied to agricultural machinery and implements, applications, harvesters, etc., can solve problems such as low mowing efficiency and uneven speed of mowing reels, so as to improve mowing efficiency and service life , the effect of uniform speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

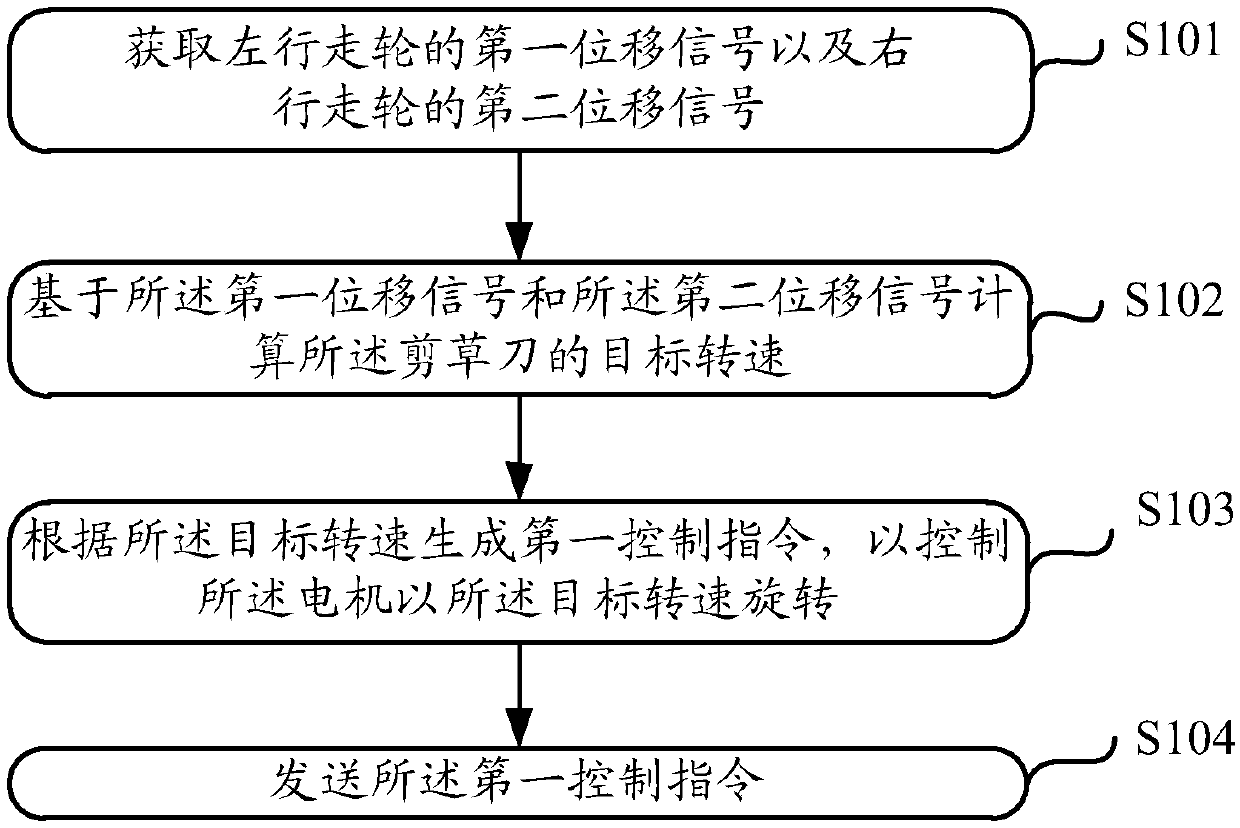

[0076] figure 1 The control method of a lawnmower provided in the embodiment of this specification is as follows. The execution body of the control method of the lawnmower may be a microprocessor, such as an MCU provided on the electronic mainboard of the lawnmower. The lawnmower includes a left traveling wheel, a right traveling wheel, a lawnmower, and a motor that drives the lawnmower to rotate. In this embodiment, the left walking wheel and the right walking wheel are two walking wheels arranged symmetrically.

[0077] Step S101: Obtain a first displacement signal of the left travel wheel and a second displacement signal of the right travel wheel;

[0078] It should be noted that the first displacement signal and the second displacement signal may be angular displacement signals or linear displacement signals.

[0079] For example: the microprocessor receives the first displacement signal and the second displacement signal sent by the displacement signal acquisition device insta...

Embodiment 2

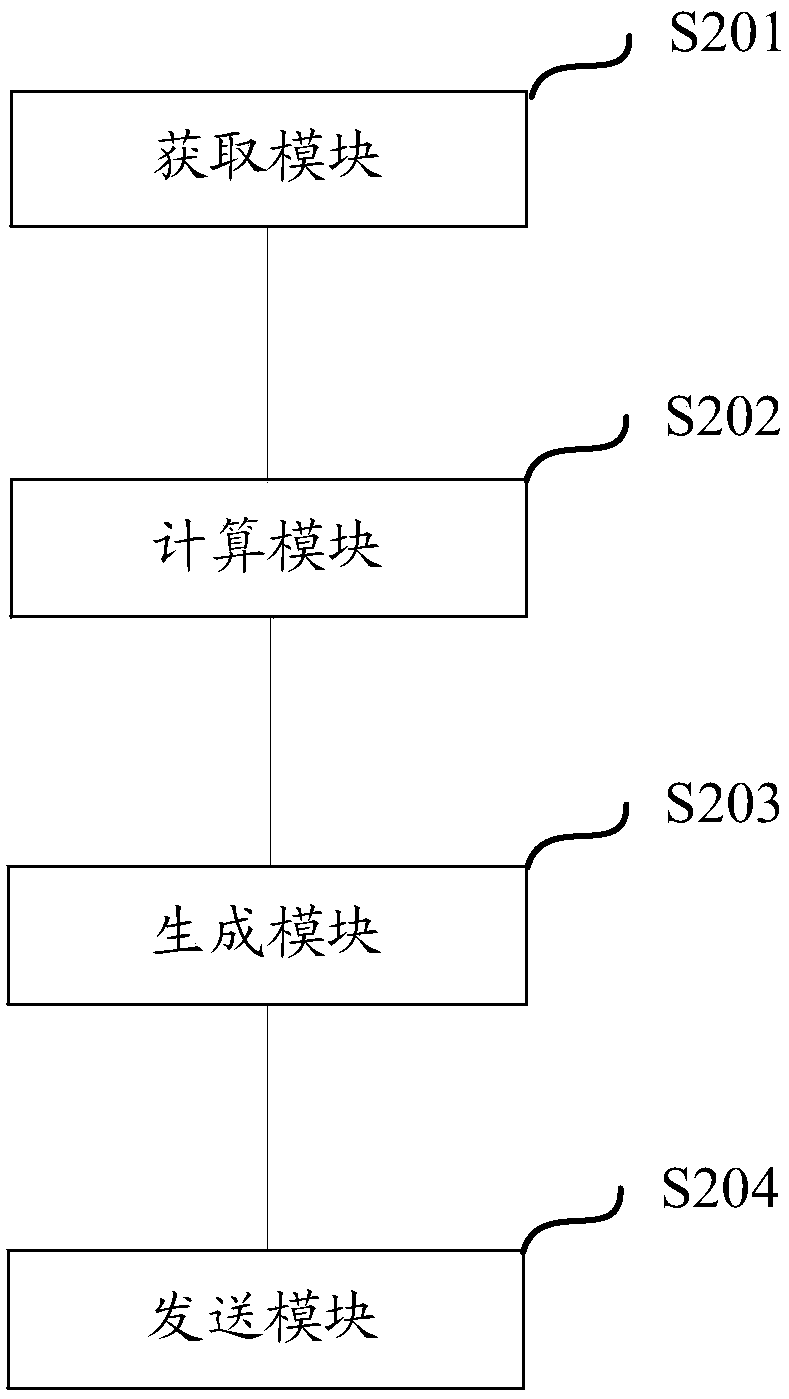

[0115] figure 2 A control device for a lawnmower provided by an embodiment of this specification, wherein the lawnmower includes a left traveling wheel, a right traveling wheel, a lawnmower, and a motor that drives the lawnmower to rotate; the control device As follows. include:

[0116] The acquiring module S201 is used to acquire the first displacement signal of the left travel wheel and the second displacement signal of the right travel wheel;

[0117] The calculation module S202 is configured to calculate the target rotational speed of the lawn mower based on the first displacement signal and the second displacement signal;

[0118] A generating module S203 is configured to generate a first control instruction based on the target speed to control the motor to rotate at the target speed;

[0119] The sending module S204 is configured to send the first control instruction.

[0120] In the embodiment of the present specification, the calculation module S202 calculating the target ro...

Embodiment 3

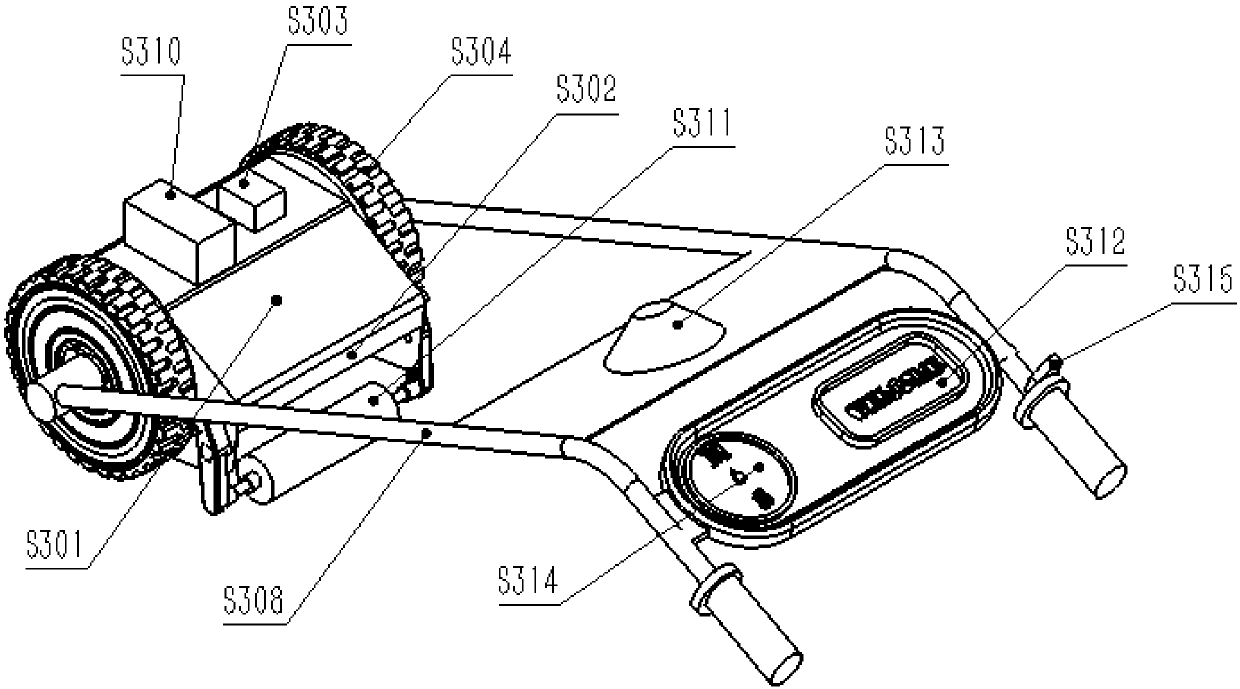

[0139] Figure 3 to Figure 4 A lawnmower provided in an embodiment of this specification is as follows. include:

[0140] Frame S301;

[0141] Grass cutting knife S302: The grass cutting knife can be a grass cutting hob.

[0142] Control device S303; The control device S303 has a structure as described in the second embodiment;

[0143] The traveling mechanism S304 is supported by the frame S301, and the traveling mechanism S304 includes at least: a left traveling wheel S305 and a right traveling wheel S306 that are symmetrically arranged;

[0144] The signal collection device S307 is installed in the walking mechanism S304 and coupled to the control device S303; the signal collection device S307 is configured to collect the displacement signals of the left travel wheel S305 and the right travel wheel S306, and Transmitting the displacement signal to the control device S303;

[0145] Handle S308, which can be installed on the walking mechanism S304 and configured to push or pull the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com