Construction method of prefabricated pressure relief cone of rebar concrete silo structure

A technology of reinforced concrete and construction method, applied in building types, buildings, large-capacity bulk material storage, etc., can solve the problems of high construction quality requirements, difficult construction of silo structures, large volume and height, etc., to save project costs , The effect of reducing on-site scaffolding and formwork support work and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

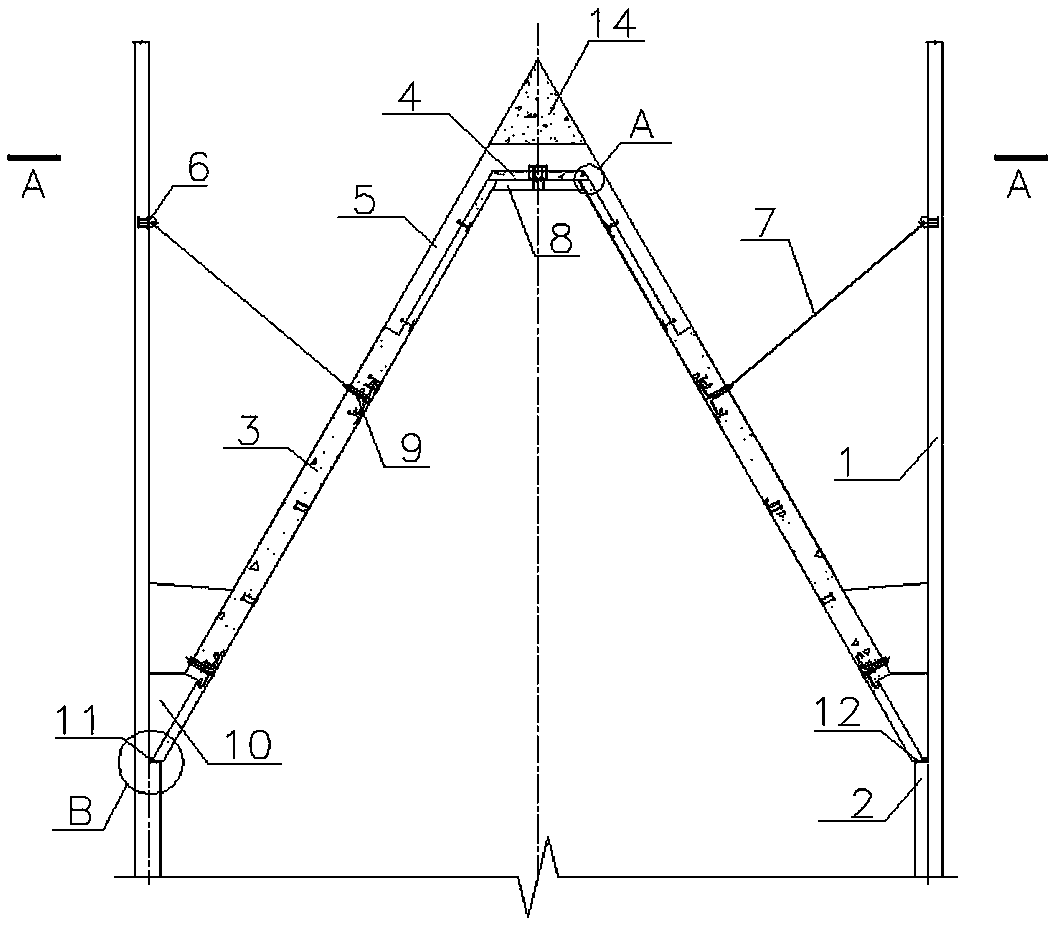

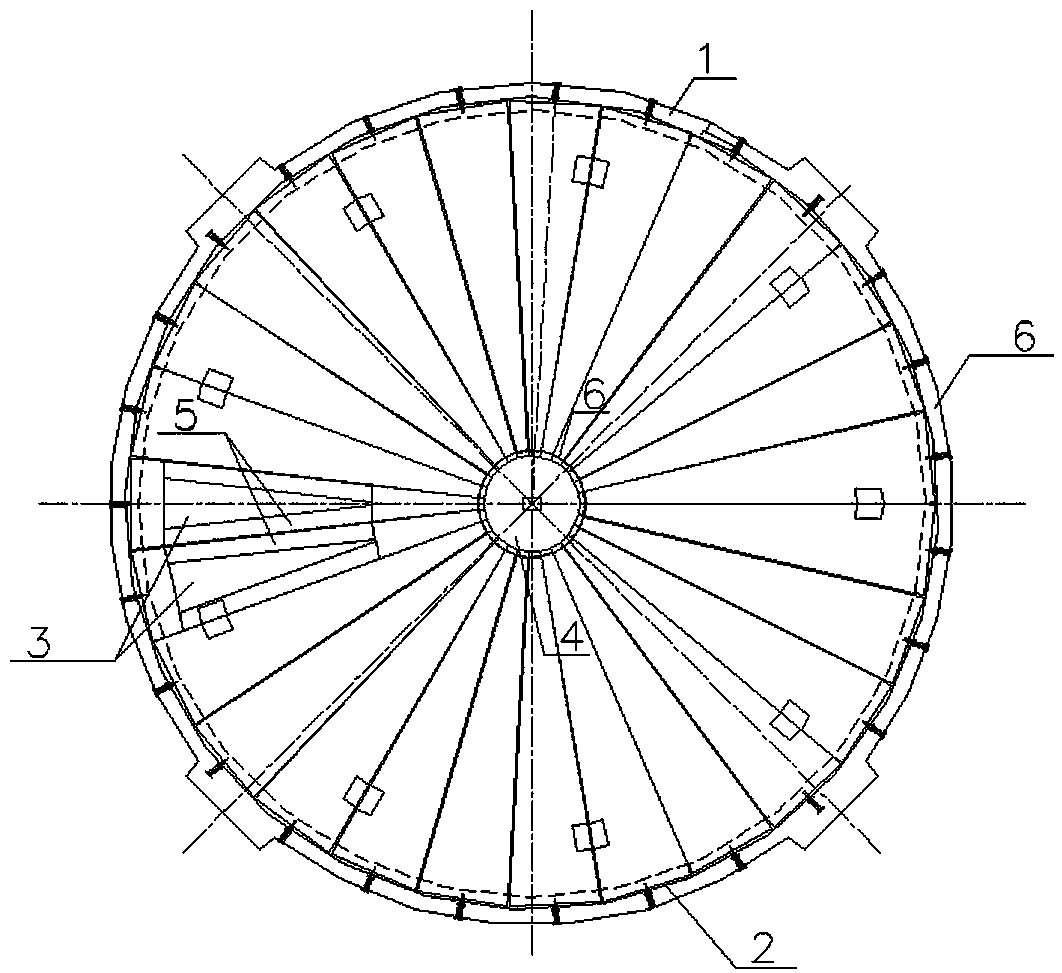

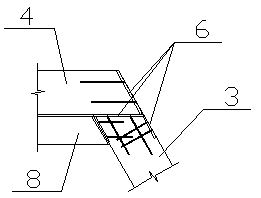

[0050] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10, a construction method of prefabricated decompression cone in reinforced concrete silo structure, according to the different diameters of the silo, the decompression cone is divided into 12-36 prefabricated panels and a top cover 4, and the decompression cone prefabricated panel 3 adopts variable The section and the bottom slab are prefabricated with concrete, and the concrete is poured after the partial post-installation. In this embodiment, the raw material warehouse with a diameter of 22m is taken as an example. The cone is divided into 27 decompression cone prefabricated panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com