Fluff removal mechanism for artificial fur knitting machine

A technology of artificial fur and knitting machine, which is applied in the directions of knitting, mechanical cleaning, textile and paper making, etc., can solve the problems of improvement, complicated de-fluffing process, unfavorable production efficiency, etc., and achieve the effect of ensuring the air suction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

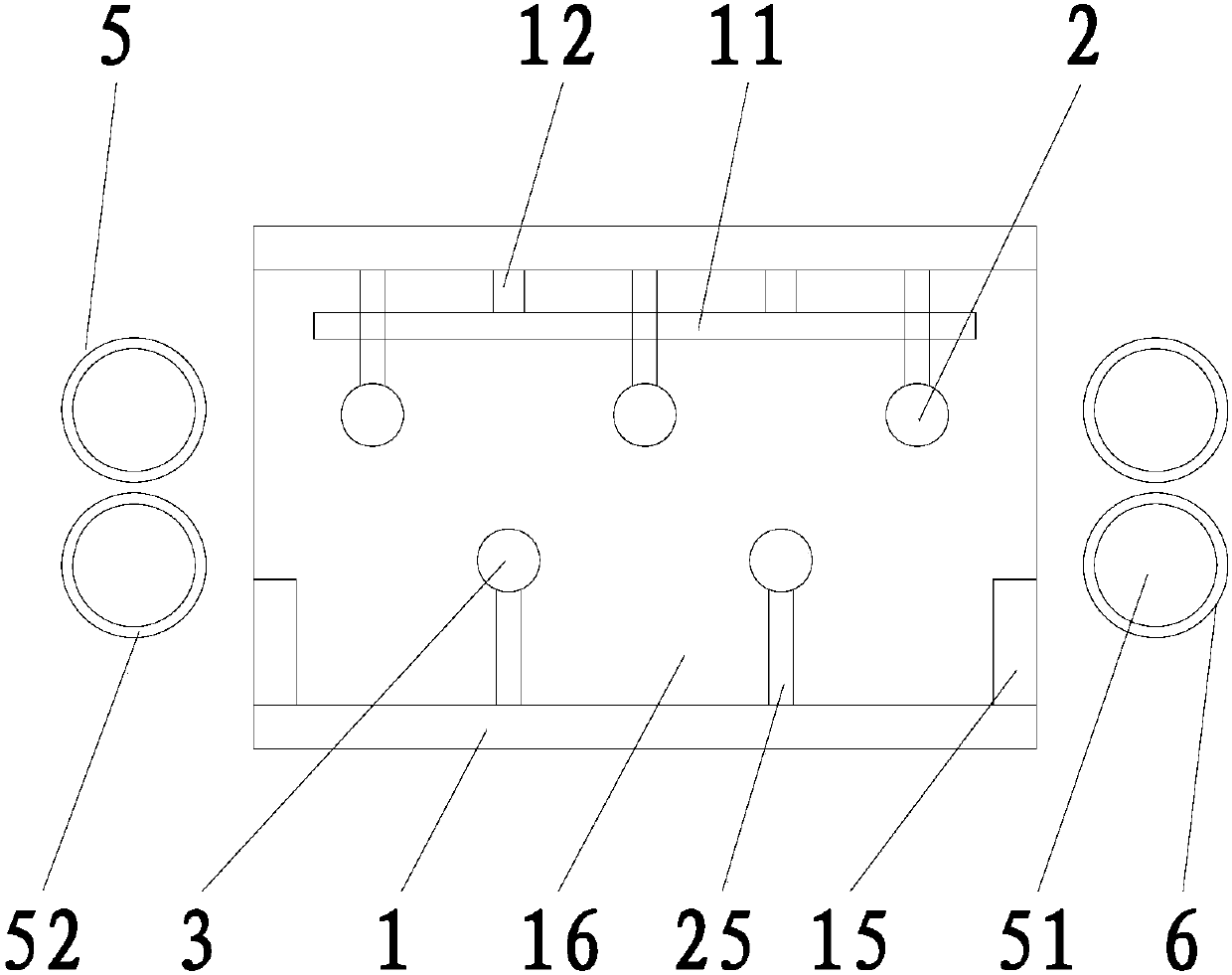

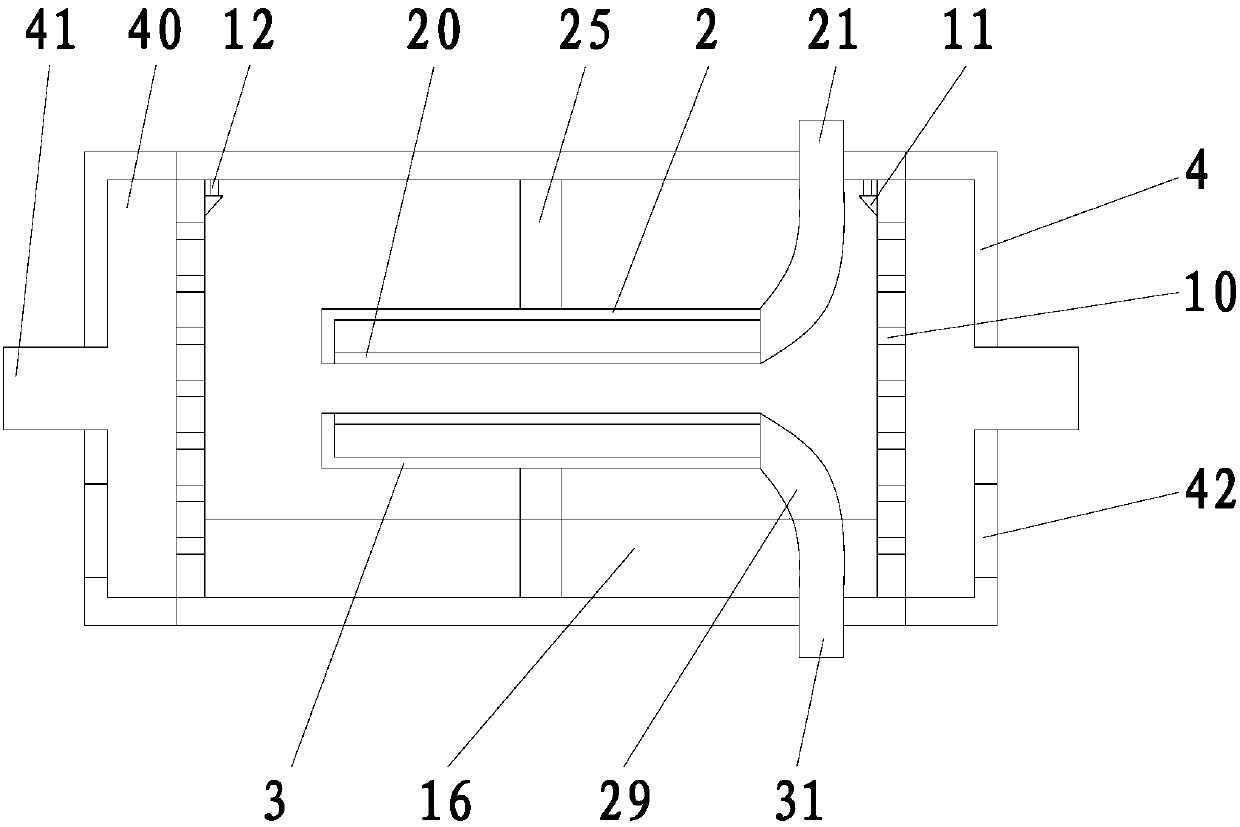

[0016] refer to figure 1 and figure 2 , a kind of fluff removal mechanism of artificial fur knitting machine of the present invention, comprises feed stick group 5, discharge stick group 6, fluff removal box 1, upper flapping stick 2, lower flapping stick 3, suction duct 41, described fluff removal Box 1 is a cuboid box body with openings at both ends of the left and right sides. The feeding stick group 5 is located on the left side of the fluff-removing box 1 body, and the discharge stick group 6 is positioned on the right side of the fluff-removing box 1 body. The fluff box 1 is provided with some upper beating sticks 2 and lower beating sticks 3. The upper beating sticks 2 are connected to the top wall of the fluff-removing box 1 through the push-pull device 25, and the lower beating sticks 3 are connected to the bottom of the fluff-removing box 1 through the push-pull device 25. The sidewalls on both sides of the front and rear sides of the fuzz removal box 1 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com