A thermal protection material anti-heat insulation test system, test method and heat treatment method

A heat protection material and test system technology, applied in the field of heat protection material heat insulation test system, can solve problems such as inability to quickly obtain multiple parameters, deviation of simulated assessment conditions, and inability to perform multiple environmental assessments, and achieve comprehensive performance evaluation and insulation resistance. The effect of realistic thermal performance and low requirements for power distribution conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: (three-chamber furnace air environment test)

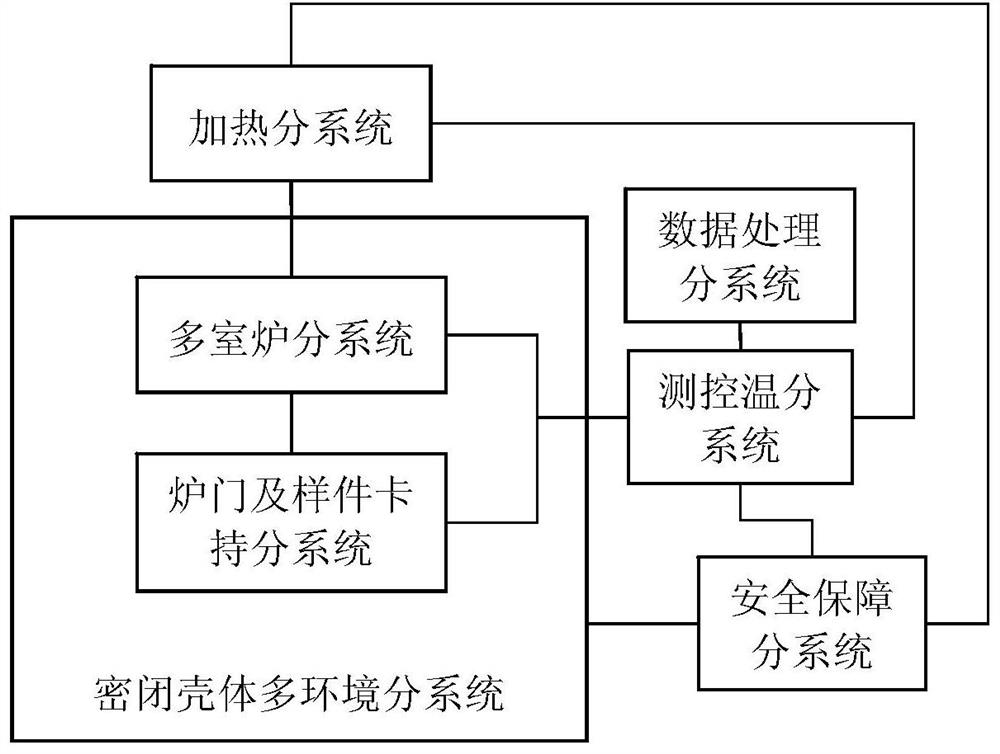

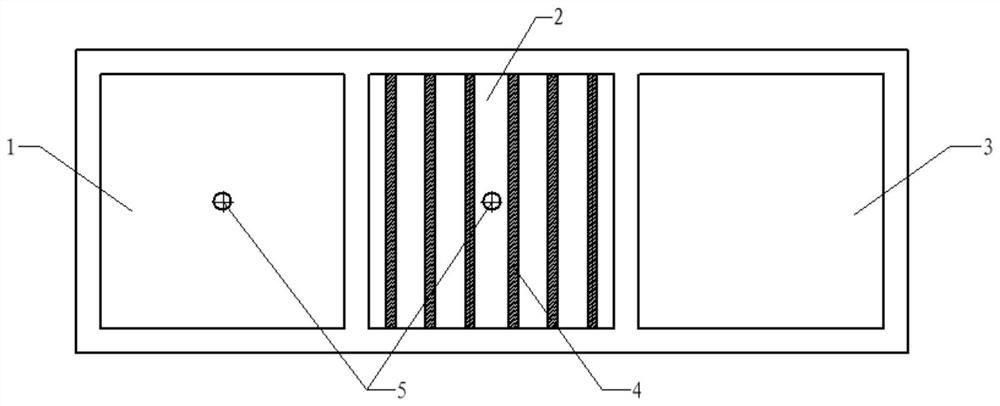

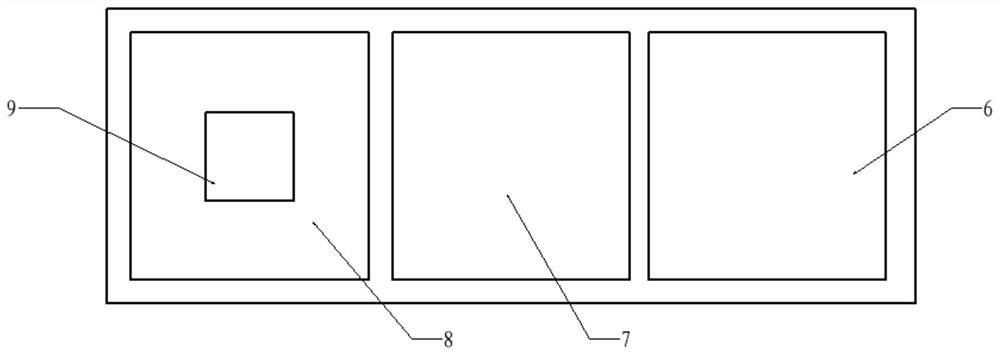

[0046] For multi-chamber furnace subsystem (three-chamber furnace subsystem see figure 2 ), furnace door and sample holder subsystem (for the furnace door and sample holder subsystem corresponding to the three-chamber furnace, see image 3 ), the heating subsystem, the measurement and control temperature subsystem and the data processing subsystem constitute the thermal protection material heat insulation test system to test the thermal insulation performance of the thermal protection material. The process is as follows:

[0047] (1) Inlaid sample: inlay the sample of the heat protection material to be tested on the furnace door corresponding to the cooling chamber, the surface to be heated faces the direction of the main heating chamber, and is flush with the surrounding furnace materials. Filling with thermal material, attach the high-temperature resistant ceramic plate with the thermocouple fixed on the b...

Embodiment 2

[0053] Embodiment 2: (controllable gas environment, four-chamber furnace test)

[0054] It is used for multi-environment subsystems and multi-chamber furnace subsystems in closed shells (for four-chamber furnace subsystems, see Figure 4 ), furnace door and sample holder subsystem (for the furnace door and sample holder subsystem corresponding to the four-chamber furnace, see Figure 5 ), the heating subsystem, the temperature measurement and control subsystem, the safety assurance subsystem and the data processing subsystem constitute the thermal protection material insulation test system to test the thermal insulation performance of the thermal protection material.

[0055] (1) Inlaid sample: inlay the sample of the heat protection material to be tested on the furnace door corresponding to the cooling chamber, the surface to be heated faces the direction of the main heating chamber, and is flush with the surrounding furnace materials. Filling with thermal material, attach t...

Embodiment 3

[0062] Embodiment 3: (controllable gas environment, three-chamber furnace sample heat treatment)

[0063] It is used for multi-environment subsystems and multi-chamber furnace subsystems in closed shells (for three-chamber furnace subsystems, see figure 2 ), furnace door and sample holder subsystem (for the furnace door and sample holder subsystem corresponding to the three-chamber furnace, see image 3 ), the heating subsystem, the measurement and control temperature subsystem, the safety assurance subsystem and the data processing subsystem. The thermal protection material heat insulation test system performs heat treatment on the thermal protection material during the preparation process. The process is as follows:

[0064] (1) Inlaid sample: Inlay the sample of heat treatment protection material to be tested on the furnace door corresponding to the cooling chamber, the surface to be heated faces the direction of the main heating chamber, and is flush with the surrounding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com