High-efficiency cleaning equipment for ships

A cleaning equipment and marine technology, which is applied in the direction of ship cleaning devices, auxiliary equipment, hulls, etc., can solve the problems of inapplicable cleaning devices, shortage of fresh water resources, limited storage space, etc., to prevent damage to human health, facilitate cycle cleaning, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

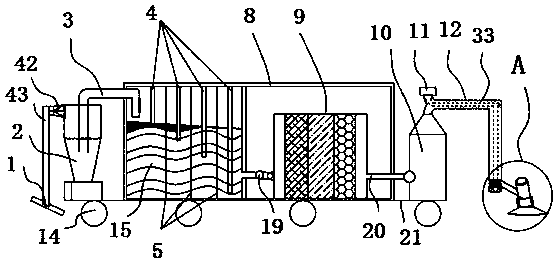

[0025] Such as Figure 1-2 As shown, the marine cleaning equipment includes a base 21, a decontamination device, and a suction device. The base 21 is provided with a suction device, and the suction device is connected to the oil-water separation and purification device 15 in the casing 8 through the sewage pipe 3, and the oil-water separation The lower right end of the purification device 15 communicates with the sewage purification device 9 in the casing 8 through the connecting pipe 19, the sewage purification device 9 communicates with the clean water pool 10 outside the casing 8 through the water inlet pipe 20, and the upper end of the clean water pool 10 is connected with the fan 11 through the water pipe 12 , the water outlet end of the water pipe 12 is connected to the decontamination device, the water pipe 12 has a built-in coaxial air outlet pipe 33, the air inlet end of the air outlet pipe 33 is connected to the air outlet end of the fan 11, and the lower end of the b...

Embodiment 2

[0029] Such as Figure 3-4 As shown, the optimization scheme of this embodiment on the basis of embodiment 1 is:

[0030] The suction device includes a decontamination suction plate 1, the decontamination suction plate 1 is connected to one end of the suction pipe 43, the other end of the suction pipe 43 is connected to the suction machine 42, and the outlet end of the suction machine 42 is connected to the sewage pool 2 , the decontamination suction flow plate 1 can rotate around the suction flow pipe 43, and the contact surface between the decontamination suction flow plate 1 and the ground is evenly distributed with square rubber bumps 36, and the surface of the square rubber bump 36 is provided with a suction flow hole 37, and the suction flow hole 37 communicates with the suction pipe 43, and square rubber bumps are evenly distributed on the contact surface between the suction plate and the ground, so that the square rubber bumps can rub against difficult-to-clean stains ...

Embodiment 3

[0032] Such as Figure 5-8 As shown, the optimization scheme of this embodiment on the basis of embodiment 1 is:

[0033] The decontamination device includes a water pipe 12, a swivel 26, and a motor 28. The bottom surface of the water pipe 12 is provided with a groove 6. The surface of the groove 6 is evenly distributed with water outlet holes 25 and air outlet grooves 27. The surface of the groove 6 is nested with a swivel 26. , the swivel 26 is connected to the outer sleeve 32 through the second water pipe 30, the second water pipe 30 has a built-in air outlet pipe 33 in communication with the air outlet groove 27, the water inlet of the second water pipe 30 is in communication with the water outlet hole 25, and the outer sleeve 32 is built in the coaxial inner The sleeve 34, the outer sleeve 32, and the inner sleeve 34 are hollow structures with a built-in second motor 31, the outer sleeve 32 and the inner sleeve 34 are connected through the bottom surface 7, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com