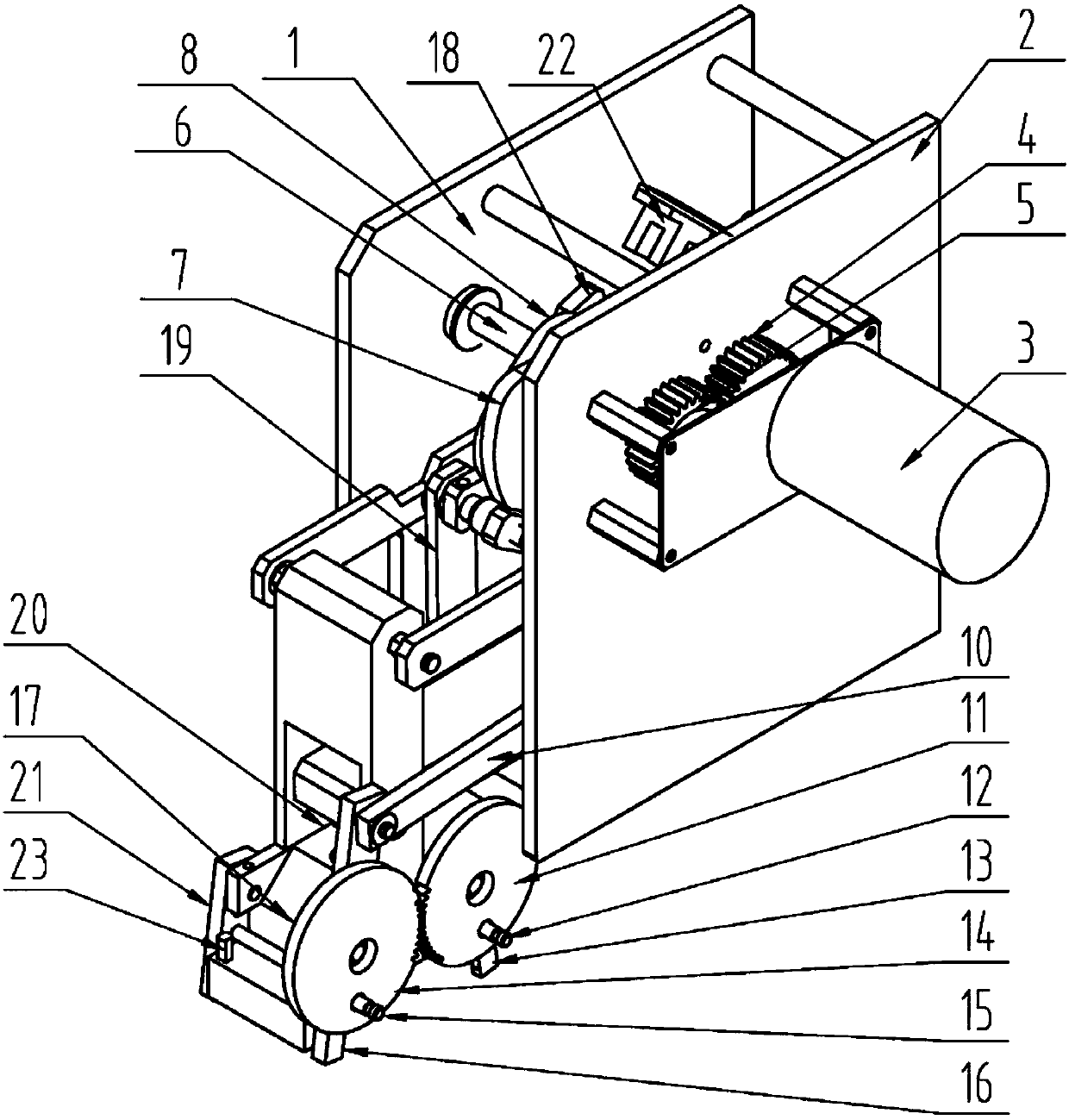

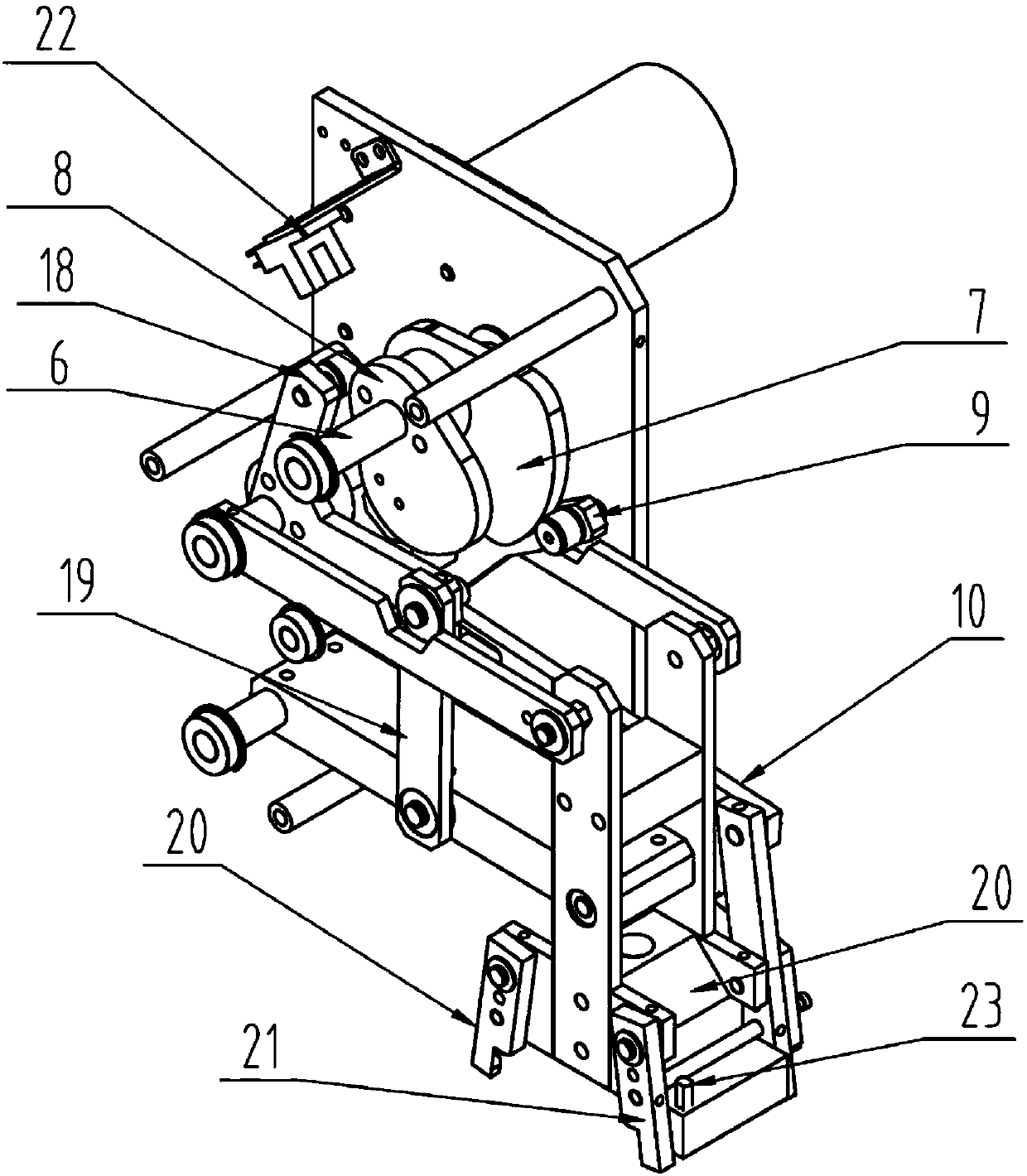

Single motor driving lifting high-precision grabbing and releasing mechanical hand and control method thereof

A manipulator, high-precision technology, applied in the field of machinery, can solve the problem of a single power-driven high-precision pick-and-place manipulator, etc., and achieve the effects of high-precision positioning, high fault tolerance, and precise pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0067] The invention has been successfully applied in a composite type X-ray fluorescence spectrometer. The instrument can detect the element content in the sample and is widely used in metallurgy, geology, building materials, environment and other fields. The invention can complete automatic sampling and unloading under the condition of unattended, which saves the physical labor of staff and greatly improves the working efficiency of the instrument.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com