Control system and method of sedimentation tank of waste gas treatment equipment

A waste gas treatment equipment and control system technology, applied in the direction of separation methods, chemical instruments and methods, feeding/discharging devices of sedimentation tanks, etc., can solve problems such as difficulty in cleaning and supplementing sedimentation tanks, judgments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

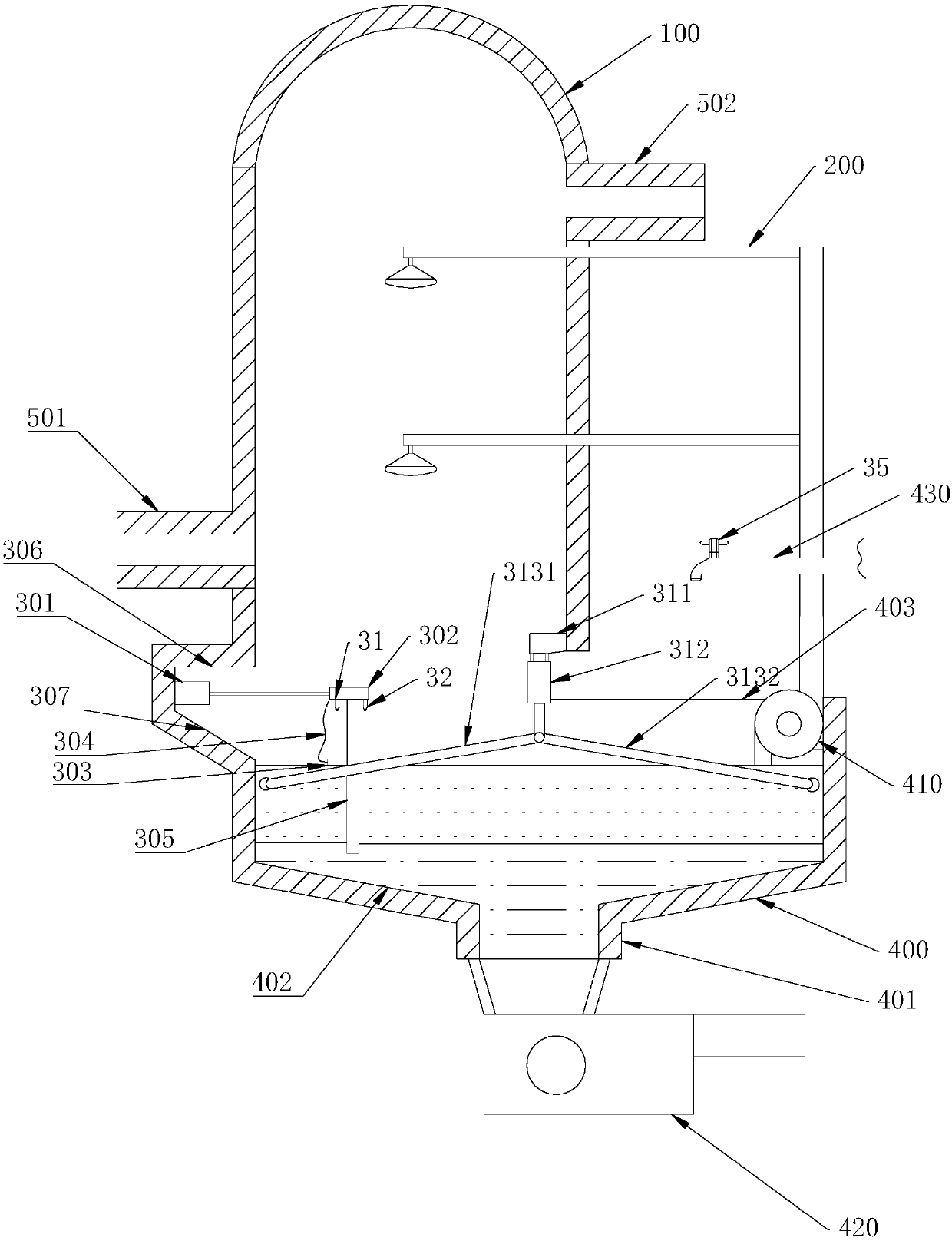

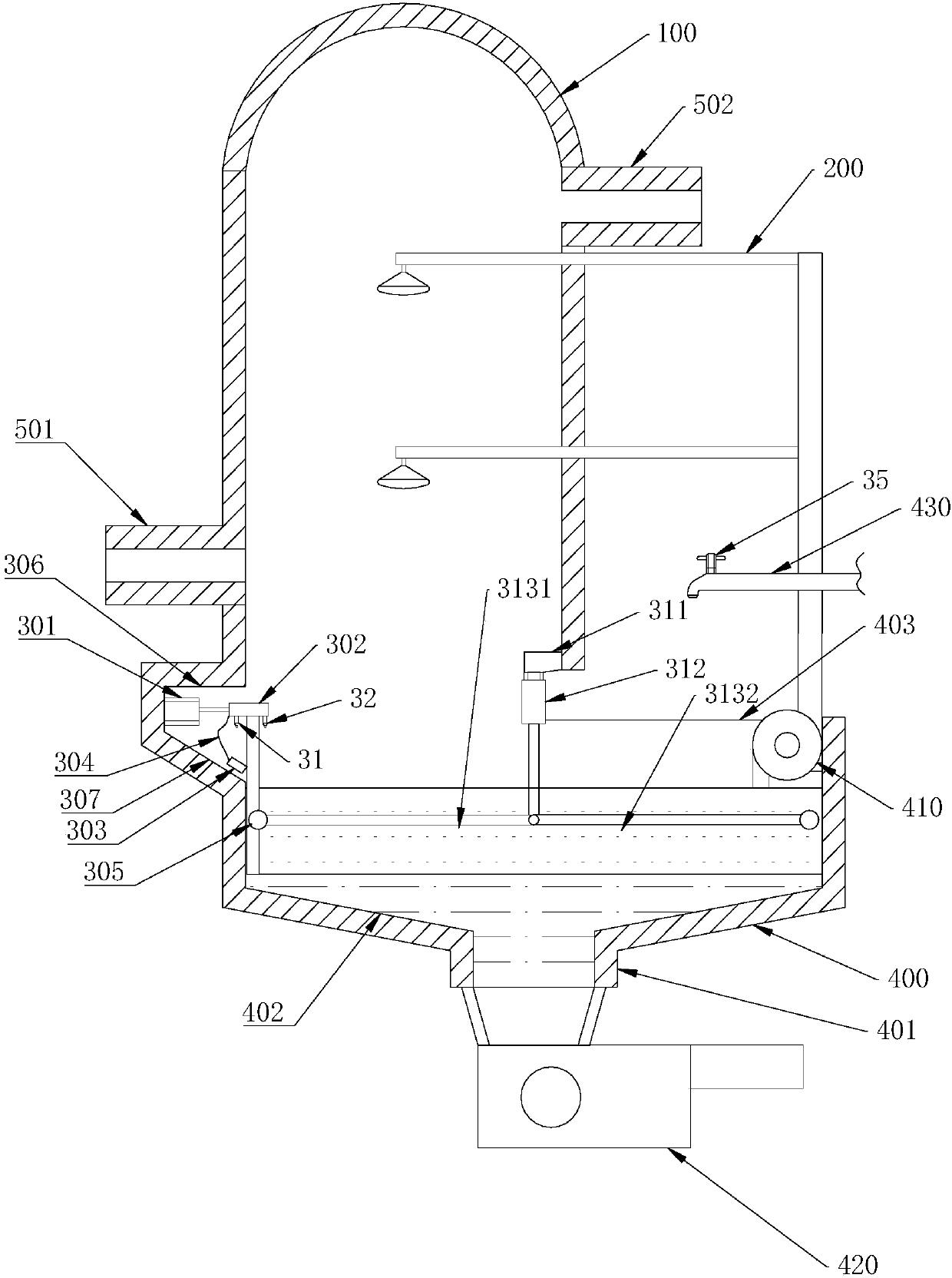

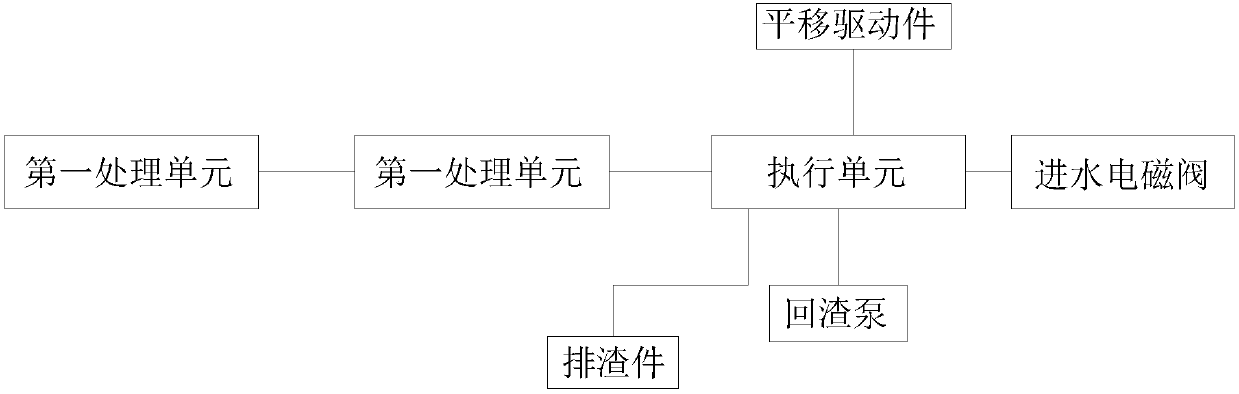

[0046] Embodiment 2, a control method for a settling tank 400 of waste gas treatment equipment, provides a control system for a settling tank 400 of waste gas treatment equipment, including an absorption tower 100, a settling tank 400, a spraying device 200, an air inlet pipe 501 and an air outlet pipe 502, The inlet pipe 501 and the outlet pipe 502 are both arranged on the absorption tower 100, the spray equipment 200 is arranged inside the absorption tower 100, and the settling tank 400 is provided with a liquid level detection structure and a slag discharge structure 34. The liquid level detection structure includes a detection bracket, a first infrared sensor 31, a second infrared sensor 32 and a floating structure, and both the first infrared sensor 31 and the second infrared sensor 32 are fixed to the sedimentation tank 400 through the detection bracket , and the first infrared sensor 31 and the second infrared sensor 32 are set downwards, the floating structure includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com