Method and device for three-dimensional curved surface nano imprinting, and die preparation method

A three-dimensional curved surface and nanoscale technology, which is applied in the field of nanoscale imprinting, can solve the problems of inability to imprint curved surface substrates, etc., and achieve the effects of simple use, cost reduction, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

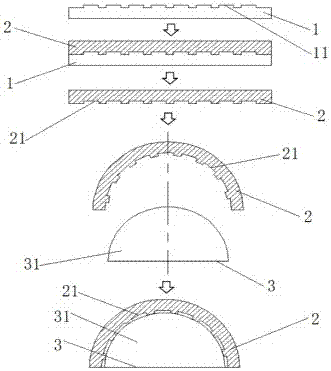

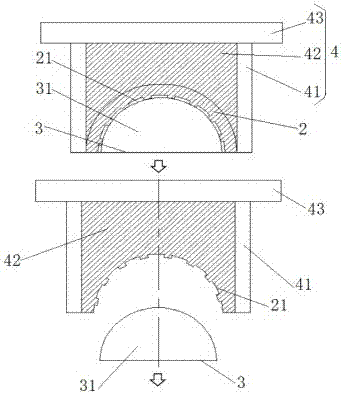

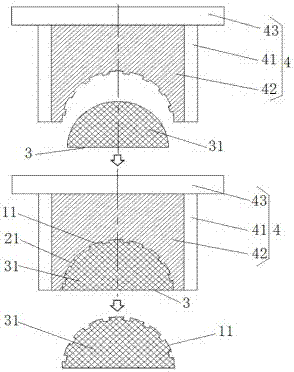

[0079] see Figure 1 to Figure 5 , the present application provides a nanoscale imprinting device for three-dimensional curved surfaces, including:

[0080] A master template 1, the top of which is formed with a predetermined concave-convex shape 11;

[0081] A base 3, the top of which is formed with an embossed three-dimensional curved surface 31;

[0082] PDMS adhesive layer 2, the bottom surface and the top of the master template 1 are cured and covered on the embossed three-dimensional curved surface 31;

[0083] The holding mechanism 4, by docking and curing the PDMS adhesive layer 2 covering the imprinted three-dimensional curved surface 31, forms the bottom surface of the PDMS adhesive layer 2 into an imprinting mold that embosses the set concave-convex shape 11 on the imprinted three-dimensional curved surface 31 .

[0084] By transferring the set concave-convex shape 11 on the master template 1 to the bottom surface of the PDMS adhesive layer 2, and then covering t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com