Method for measuring deviation between mechanical center of rectangular beam transmitting device and beam center

A technology of beam emission and rectangular shape, which is applied in the field of optical measurement, can solve the problems that it is not easy to adjust the mechanical center to adjust the outgoing beam, and the spatial position of the outgoing beam is difficult to determine, and achieve the effects of performance improvement, simple equipment structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

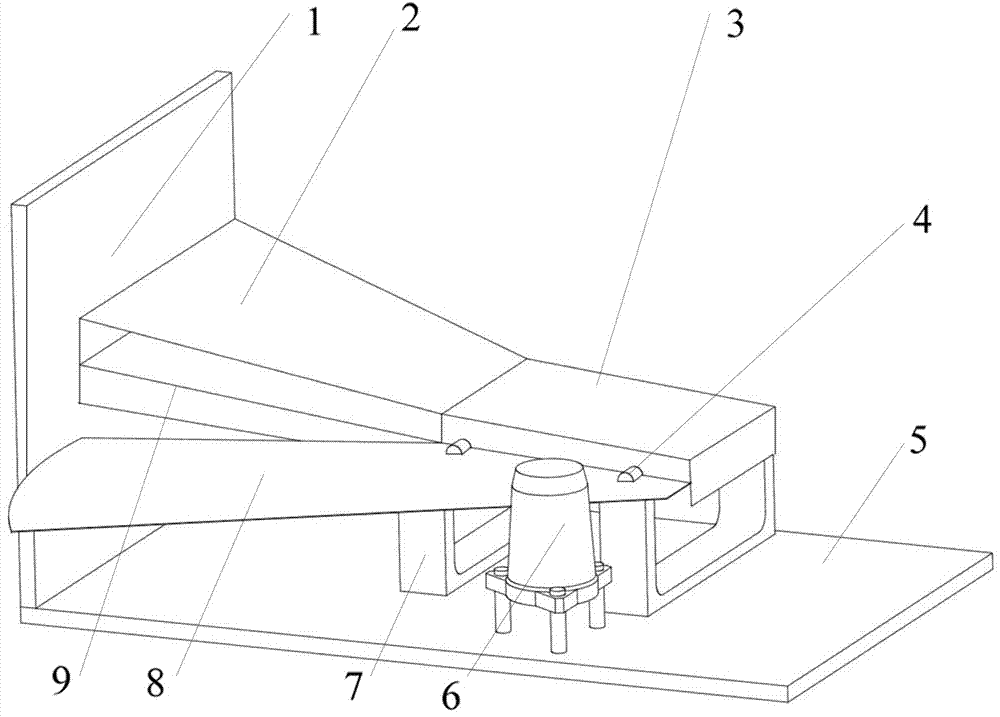

[0016] Provide the specific embodiment of the test device that uses the method of the present invention to build below in conjunction with accompanying drawing, as figure 1 Shown:

[0017] The invention discloses a method for measuring the deviation between the mechanical center and the beam center of a rectangular beam emitting device with a laser level, figure 1 Shown is a basic embodiment of the test device built using the method of the present invention, the test device comprises a rectangular beam emitting device 3, comprising a first support system 5 and a second support system 7 of the rectangular beam emitting device 3, comprising A laser level 6 for indicating the height of the front and rear axis 4 of the rectangular beam emitting device 3, which also provides a laser level 8 for the rectangular beam 2 for reference; includes a vertical plate 1 for receiving the rectangular beam 2 and the laser level 8.

[0018] Such as figure 1 As shown, the rectangular beam emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com