Compound corrugated tube heat exchanger

A technology of corrugated tubes and heat exchangers, applied in the direction of heat exchangers, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problems of inability to recycle various fluid media, and reduce equipment weight and reduce Equipment manufacturing cost, effect of reducing fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

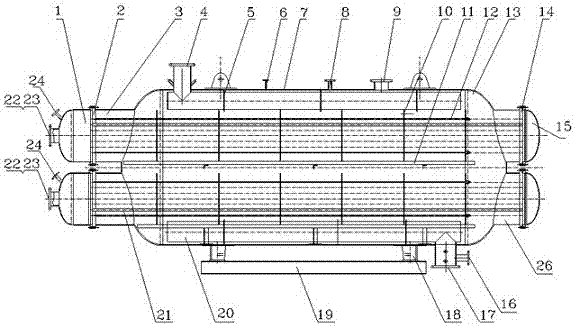

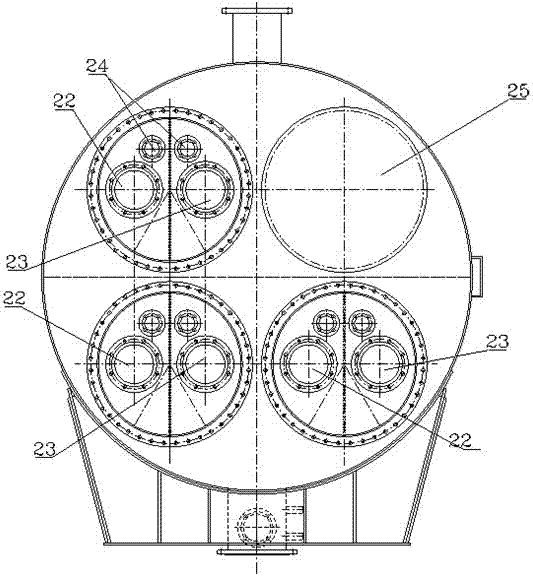

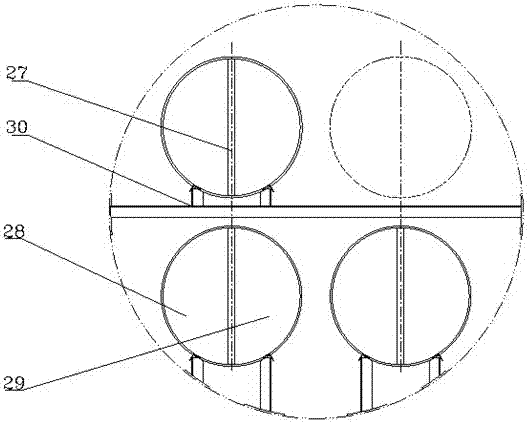

[0024] see figure 1 , figure 2 , a compound corrugated tube heat exchanger, including a shell-side part 13 and 4 tube-side parts, wherein one tube-side part is reserved, and no heat exchange tube is installed temporarily; each of the tube-side parts includes Tube side inlet tube 22, tube side outlet tube 23, multiple corrugated heat exchange tubes 21, the shell side part 13 includes a shell side cylinder body 7, a shell side inlet tube 17, and a shell side outlet tube 4; The left end of the shell-side cylinder 7 is provided with four left guide tubes 3 communicating with the inner cavity of the shell-side cylinder 7, and the outer ends of the three left guide tubes 3 are provided with a left tube plate 2 with several tube holes. The right end of the shell side cylinder body 7 is provided with 4 and communicates with the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com