Shaft seal structure

A technology of shaft sealing and sealing rings, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of large-scale production passiveness and fuel consumption increase, on-site environmental pollution, skeleton oil seal leakage, etc., and achieve self-adjustment recovery sealing, ensuring Does not leak outside and ensures the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

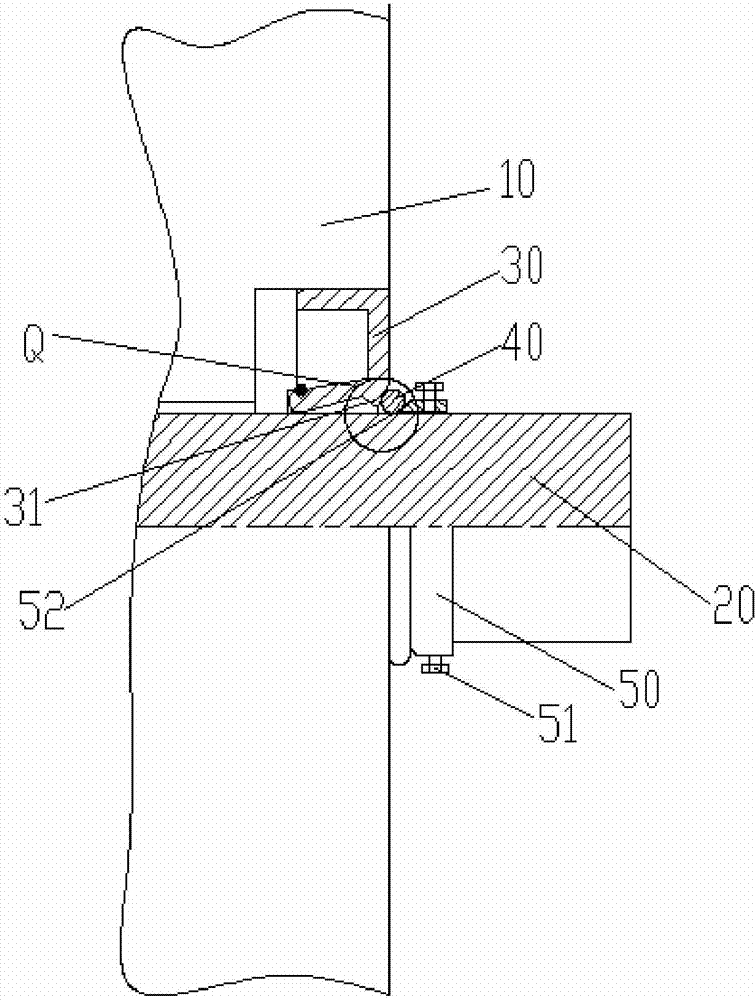

[0019] see figure 1 — Figure 4 , the shaft seal structure claimed in the present invention includes a casing 10, a rotating shaft 20 that is arranged in the casing 10 and protrudes outward relative to the casing 10, wherein the rotating shaft 20 and the casing 10 are sealed with a skeleton The ring 30 is sealed.

[0020] The skeleton sealing ring 30 is provided with a dust-proof ring 31 , and the dust-proof ring 31 is attached to the rotating shaft 20 to form an oil seal. That is to say, the skeleton sealing ring 30 of this embodiment has a dustproof ring 31 , and an oil seal is formed between the dustproof ring 31 and the rotating shaft 20 to achieve sealing.

[0021] It can be understood that the rotating shaft 20 rotates at a high speed relative to the dustproof ring 31 during operation, and the dustproof ring 31 is attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com