Intelligent temperature-control high-temperature-resistant fluorine-lined magnetic pump

A fluorine-lined magnetic force and intelligent temperature control technology, which is applied in the direction of pumps, pump control, pump devices, etc., can solve the problems of excessive cooling water, increased operating costs, and high energy consumption, so as to ensure safe transportation, reduce maintenance costs, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

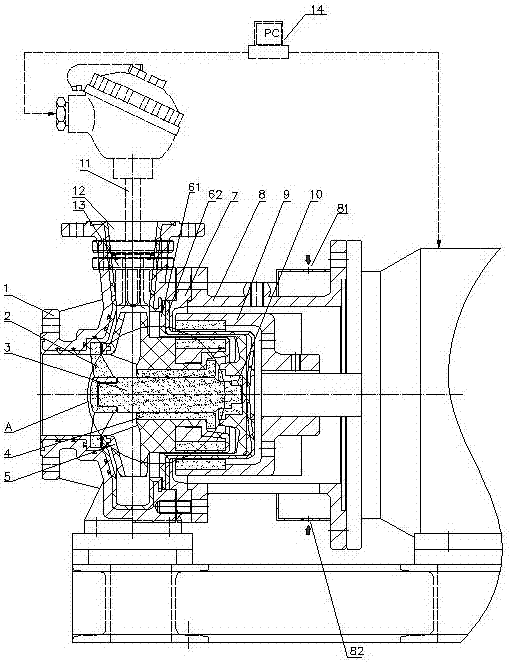

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

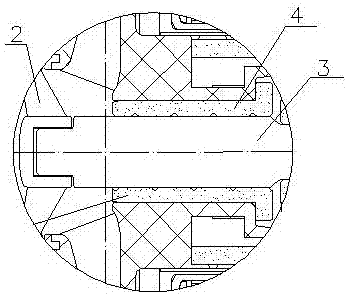

[0021] Such as Figure 1-3 As shown in , an intelligent temperature-controlled high-temperature-resistant fluorine-lined magnetic pump includes pump body 1, pump body static ring 2, impeller 5, pump shaft 3, shaft sleeve 4, spacer sleeve assembly, thrust bearing 10, and pressure plate 7 , bracket 8, external magnet 9, temperature sensor 11, the static ring 2 of the pump body, the thrust bearing 10 and the spacer sleeve assembly are assembled to form a support assembly, and the support assembly reduces the bearing moment and displacement in the form of span support , so that the magnetic pump can operate continuously and stably under high temperature and high pressure conditions without breaking the pump shaft 3, and improve the continuous service life of the pump shaft 3 and the magnetic pump;

[0022] The back of the outer magnet 9 is provided with blades, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com