Food material method

A material and material sorting technology, which is applied in the field of material material, can solve the problems of slow material sorting speed and poor material material accumulation ability, and achieve the effect of improving packaging efficiency, increasing the arrangement and accumulation capacity, and improving the efficiency of material arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

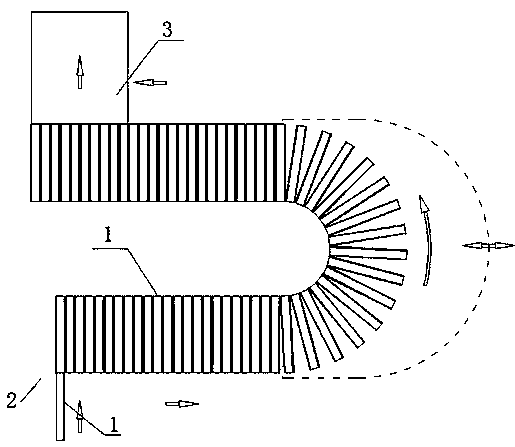

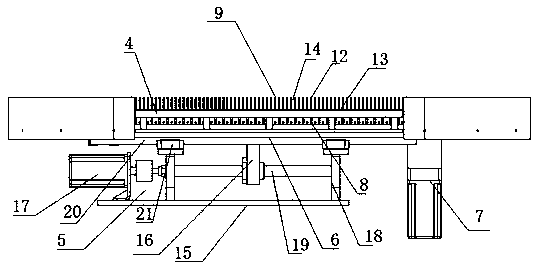

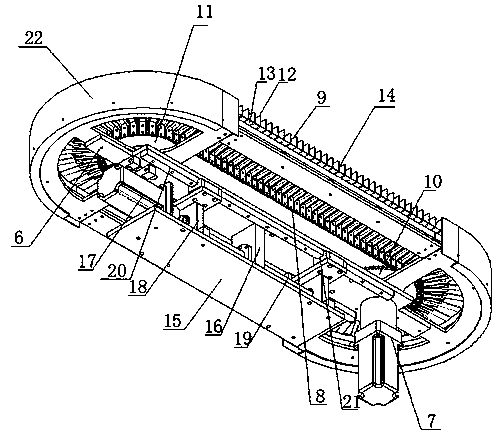

[0029] As a preferred embodiment of the present invention, with reference to the attached figure 1 , the invention discloses:

[0030] A material preparation method, comprising the steps of:

[0031]Material conveying step: the materials are conveyed to the material arrangement step one by one; the material arrangement step: the conveyed materials are arranged side by side, and continue to be conveyed to the turning step perpendicular to the conveying direction of the material conveying step; turning step: the materials conveyed by the material arrangement step are along the The arc trajectory continues to be conveyed to the reverse arrangement step; the reverse arrangement step: the materials conveyed by the turning step are arranged side by side and conveyed along the direction opposite to the conveying direction of the material arrangement step; the materials of arranging a set amount form a group of materials, and the group of materials is formed by The discharge end is o...

Embodiment 2

[0033] As another preferred embodiment of the present invention, with reference to the attached figure 1 , the invention discloses:

[0034] A material preparation method, comprising the steps of:

[0035] Material conveying step: the materials are conveyed to the material arrangement step one by one; the material arrangement step: the conveyed materials are arranged side by side, and continue to be conveyed to the turning step perpendicular to the conveying direction of the material conveying step; turning step: the materials conveyed by the material arrangement step are along the The arc trajectory continues to be conveyed to the reverse arrangement step; the reverse arrangement step: the materials conveyed by the turning step are arranged side by side and conveyed along the direction opposite to the conveying direction of the material arrangement step; the materials of arranging a set amount form a group of materials, and the group of materials is formed by The discharge e...

Embodiment 3

[0038] As another preferred embodiment of the present invention, with reference to the attached figure 1 , the invention discloses:

[0039] A material preparation method, comprising the steps of:

[0040] Material conveying step: the materials are conveyed to the material arrangement step one by one; the material arrangement step: the conveyed materials are arranged side by side, and continue to be conveyed to the turning step perpendicular to the conveying direction of the material conveying step; turning step: the materials conveyed by the material arrangement step are along the The arc trajectory continues to be conveyed to the reverse arrangement step; the reverse arrangement step: the materials conveyed by the turning step are arranged side by side and conveyed along the direction opposite to the conveying direction of the material arrangement step; the materials of arranging a set amount form a group of materials, and the group of materials is formed by The discharge e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com