A steering wheel automatic control device and its installation method

An automatic control device and steering wheel technology, applied in the field of construction machinery, can solve the problems of laborious manual operation of the steering wheel, difficult to turn the steering wheel, time-consuming and laborious, etc., and achieve the effect of flexible switching, rapid increase of automatic control functions, and flexible switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

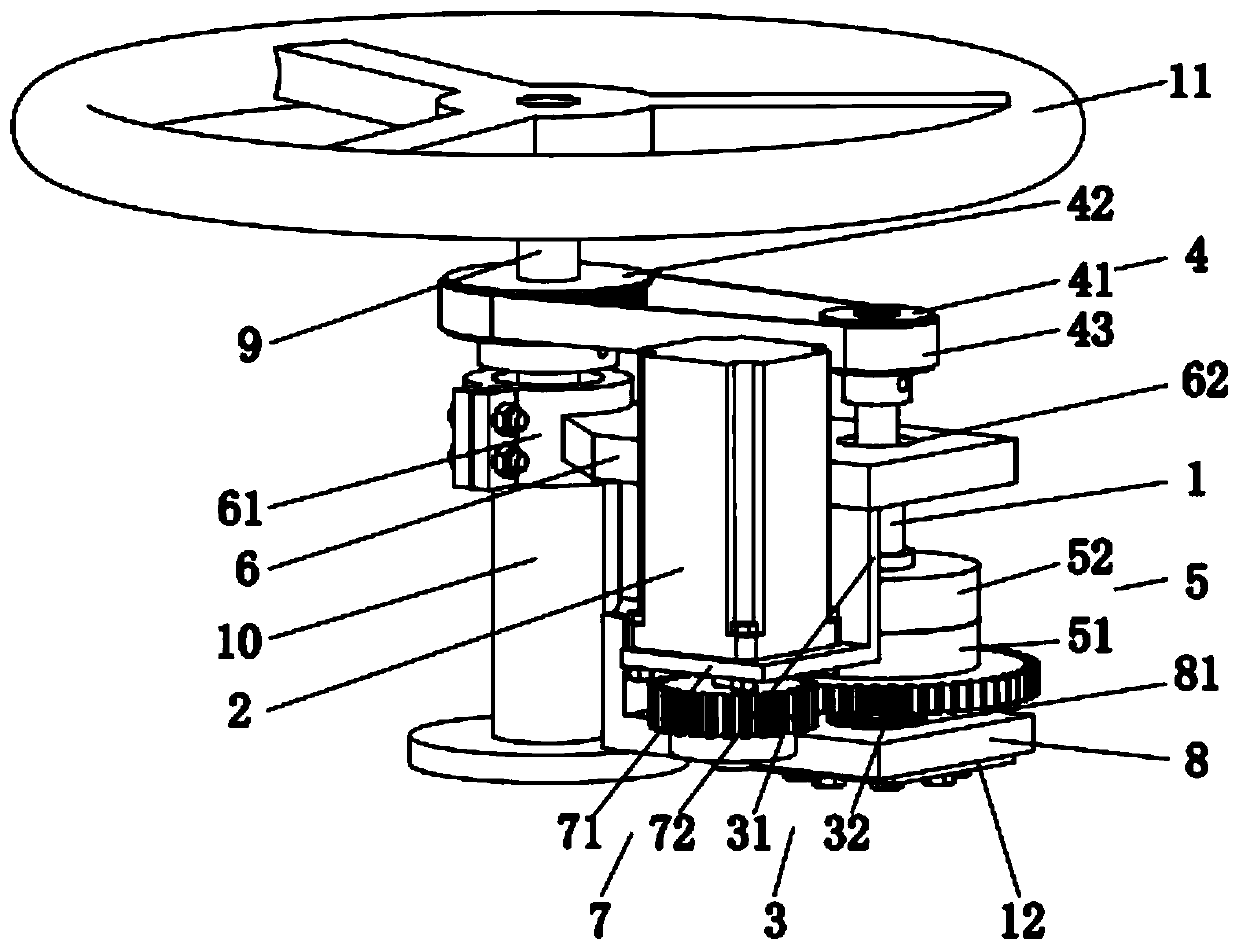

[0044] figure 1 It is a structural schematic diagram of an automatic steering wheel control device provided in Embodiment 1 of the present invention.

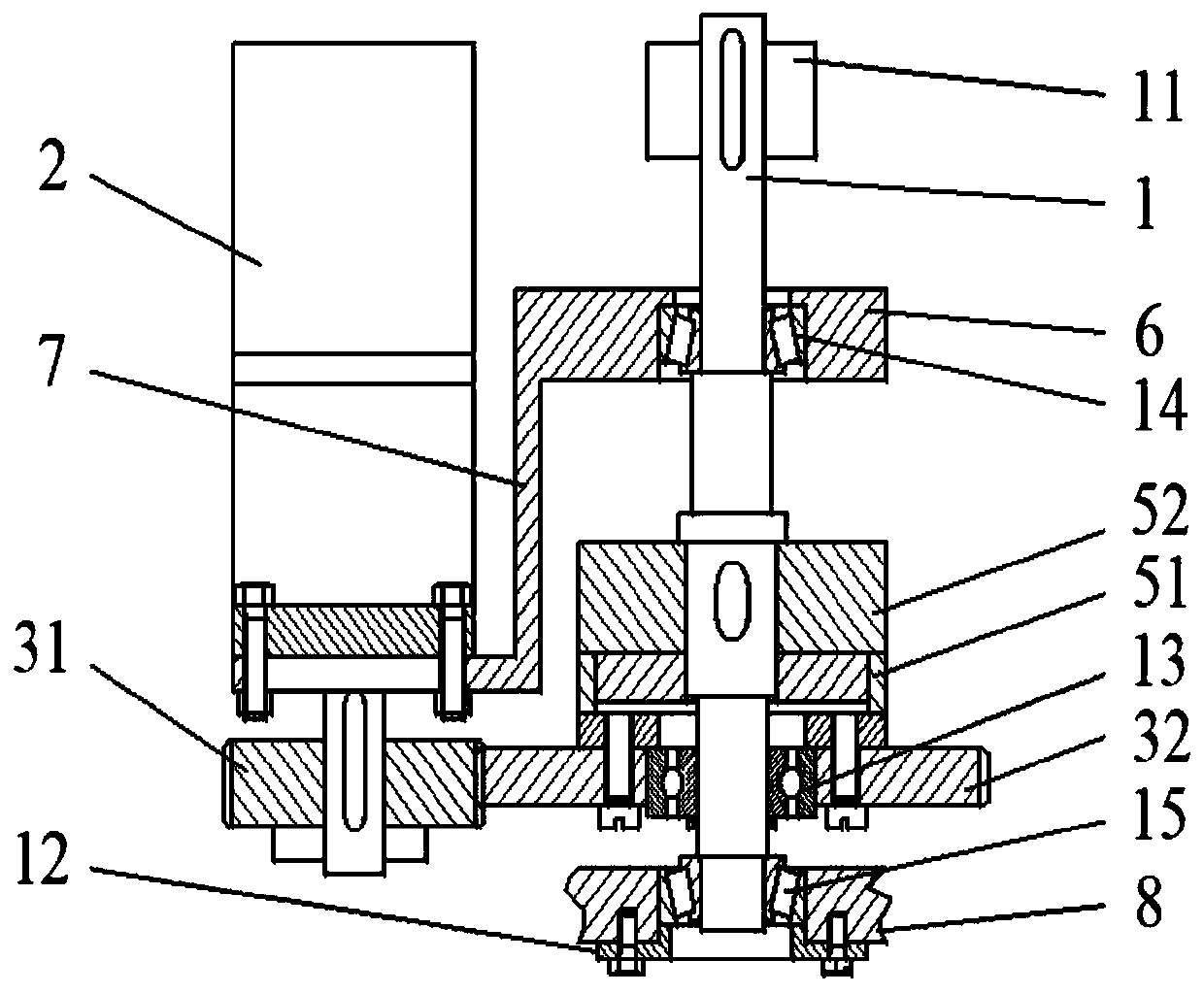

[0045] figure 2 It is a schematic cross-sectional view of an automatic steering wheel control device provided in Embodiment 1 of the present invention.

[0046] Please refer to figure 1 , figure 2, The present invention provides an automatic steering wheel control device, including: an intermediate shaft 1, a motor 2, a first transmission mechanism 3, a second transmission mechanism 4, and an electromagnetic clutch 5.

[0047] The intermediate shaft 1 is arranged on one side of the steering wheel axis 9 and is parallel to the steering wheel axis 9 .

[0048] The motor 2 is arranged on one side of the intermediate shaft 1 and is parallel to the intermediate shaft 1 .

[0049] Optionally, the motor 2 is a stepping motor, but the present invention is not limited thereto, and the motor 2 can also be other types of motors.

...

Embodiment 2

[0088] Figure 6 It is a flow chart of an installation method of an automatic steering wheel control device provided in Embodiment 2 of the present invention.

[0089] Please refer to Figure 6 , the invention provides a method for installing an automatic steering wheel control device, comprising the following steps:

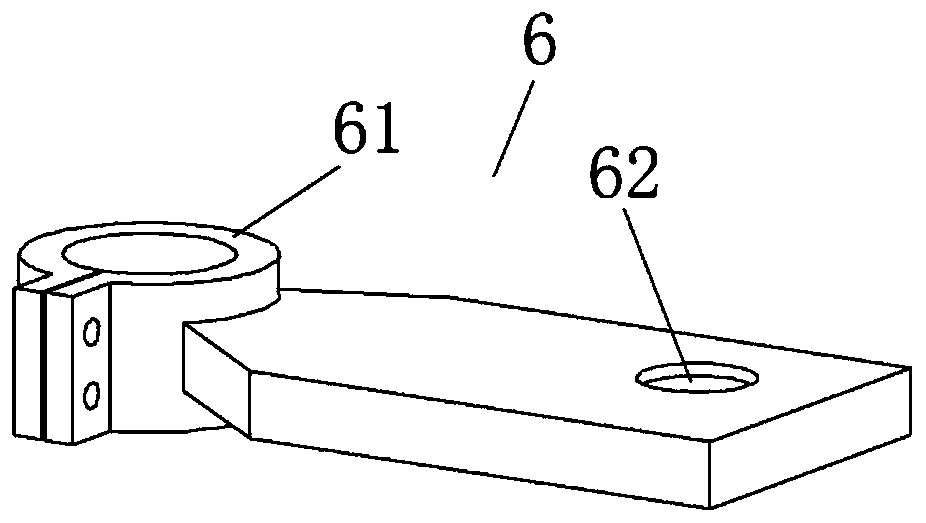

[0090]S1, remove the steering wheel 11 from the steering wheel shaft 9, and saw off the steering wheel sleeve 10 with a preset length. Wherein, the preset length is the calculated length of the steering wheel sleeve 10 that should be cut off according to the installation requirements of the clamping portion 61 of the first fixing frame 6 .

[0091] S2, using the clamping portion 61 of the first fixing bracket 6 to fix the first fixing bracket 6 on the steering wheel sleeve 10 . Specifically, bolts and nuts are used to fix the clamping portion 61 on the steering wheel sleeve 10 .

[0092] S3, fix the motor 2 on the motor fixing plate 71 of the second fixing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com