PET blister box raw material mixing machine for food production packing

A technology for packaging and blister boxes, which is applied in the field of PET blister box raw material mixers for food production and packaging, can solve the problems of not being able to save manpower, preventing dust, shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

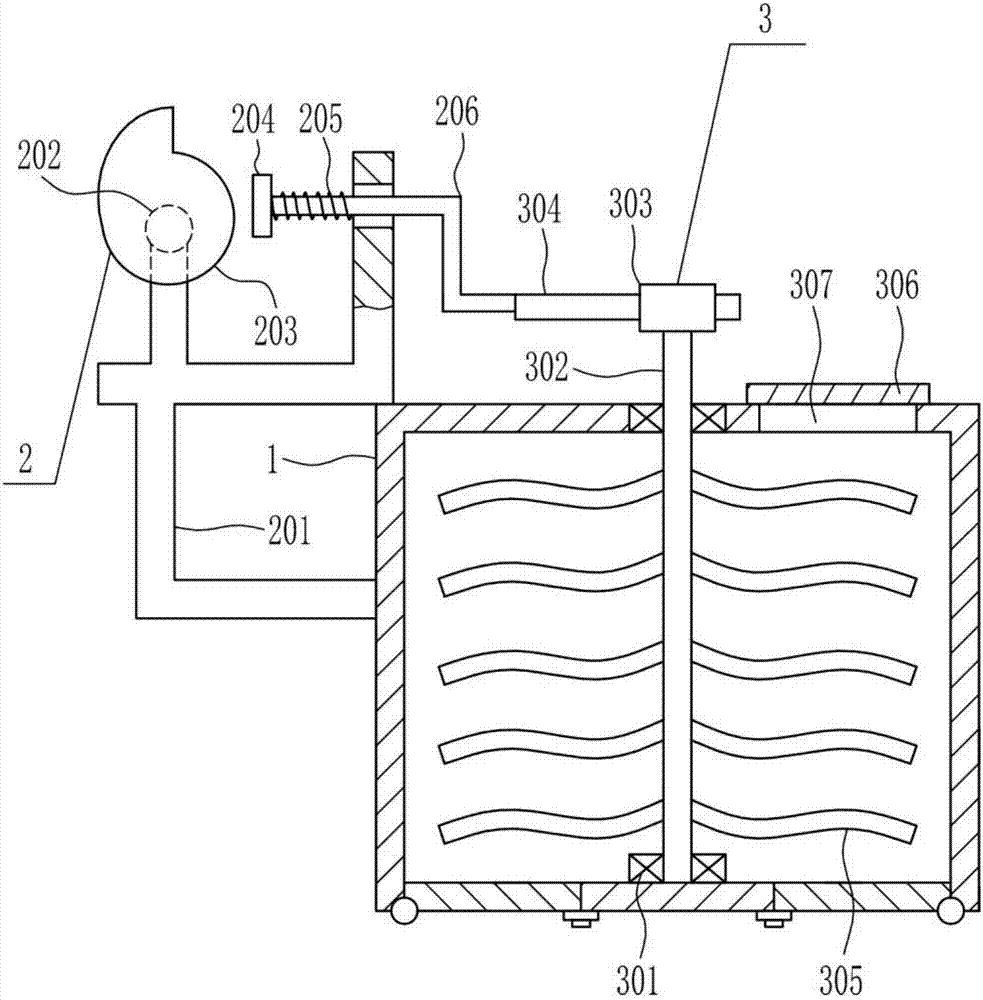

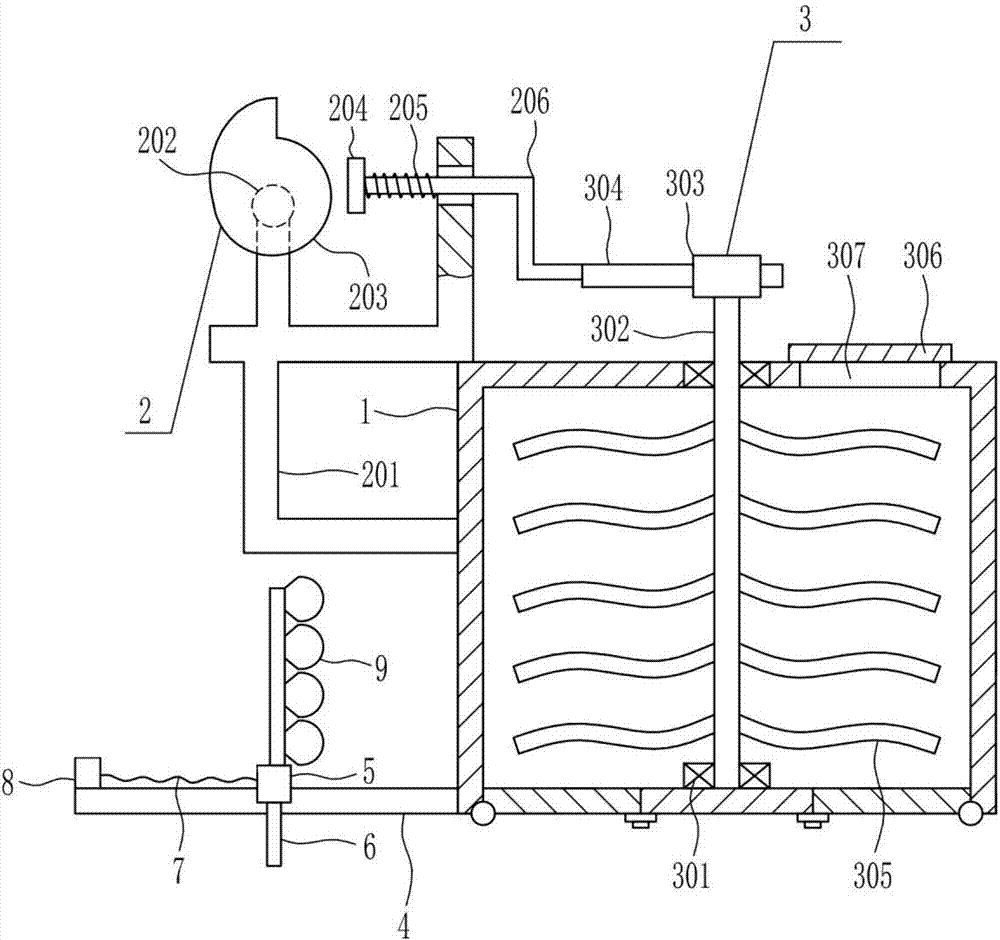

[0032] A PET blister box raw material mixer for food production and packaging, such as Figure 1-5 As shown, it includes a box body 1 , a driving mechanism 2 and a mixing mechanism 3 , the top left side of the box body 1 is connected to the driving mechanism 2 , and the box body 1 is connected to the mixing mechanism 3 .

Embodiment 2

[0034] A PET blister box raw material mixer for food production and packaging, such as Figure 1-5 As shown, it includes a box body 1 , a driving mechanism 2 and a mixing mechanism 3 , the top left side of the box body 1 is connected to the driving mechanism 2 , and the box body 1 is connected to the mixing mechanism 3 .

[0035] The driving mechanism 2 includes a mounting column 201, a servo motor 202, a cam 203, a contact block 204, a first spring 205 and a moving rod 206. The upper left side of the box body 1 is connected to the mounting column 201, and the top left side of the mounting column 201 is connected to a servo motor. Motor 202, the output shaft of servo motor 202 is connected with cam 203, the first spring 205 is connected with the upper left side of the right part of mounting column 201, and the end of first spring 205 is connected with contact block 204, and contact block 204 cooperates with cam 203, contacts A moving rod 206 is connected to the right side of t...

Embodiment 3

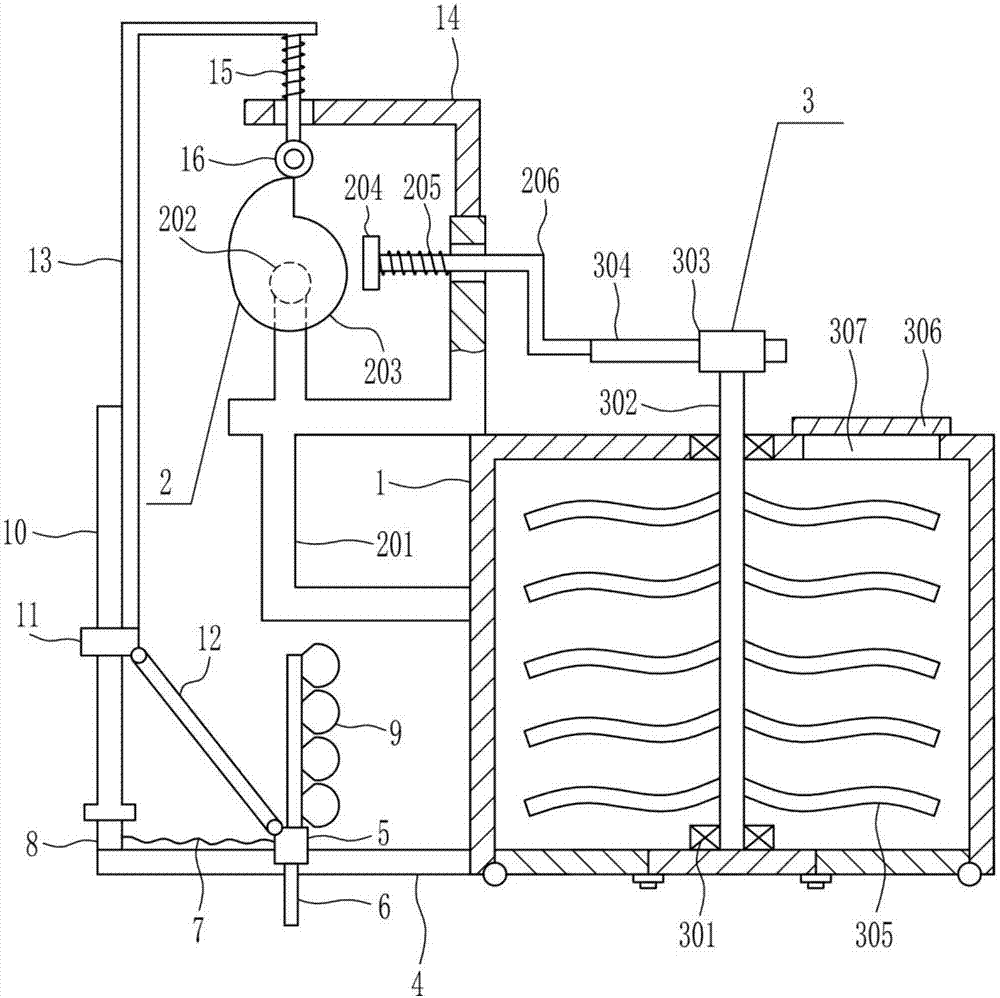

[0037] A PET blister box raw material mixer for food production and packaging, such as Figure 1-5 As shown, it includes a box body 1 , a driving mechanism 2 and a mixing mechanism 3 , the top left side of the box body 1 is connected to the driving mechanism 2 , and the box body 1 is connected to the mixing mechanism 3 .

[0038] The driving mechanism 2 includes a mounting column 201, a servo motor 202, a cam 203, a contact block 204, a first spring 205 and a moving rod 206. The upper left side of the box body 1 is connected to the mounting column 201, and the top left side of the mounting column 201 is connected to a servo motor. Motor 202, the output shaft of servo motor 202 is connected with cam 203, the first spring 205 is connected with the upper left side of the right part of mounting column 201, and the end of first spring 205 is connected with contact block 204, and contact block 204 cooperates with cam 203, contacts A moving rod 206 is connected to the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com