Gluing equipment for electronic component production

A technology for electronic components and gluing, applied in coating, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of uneven gluing, complicated operation, labor-intensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

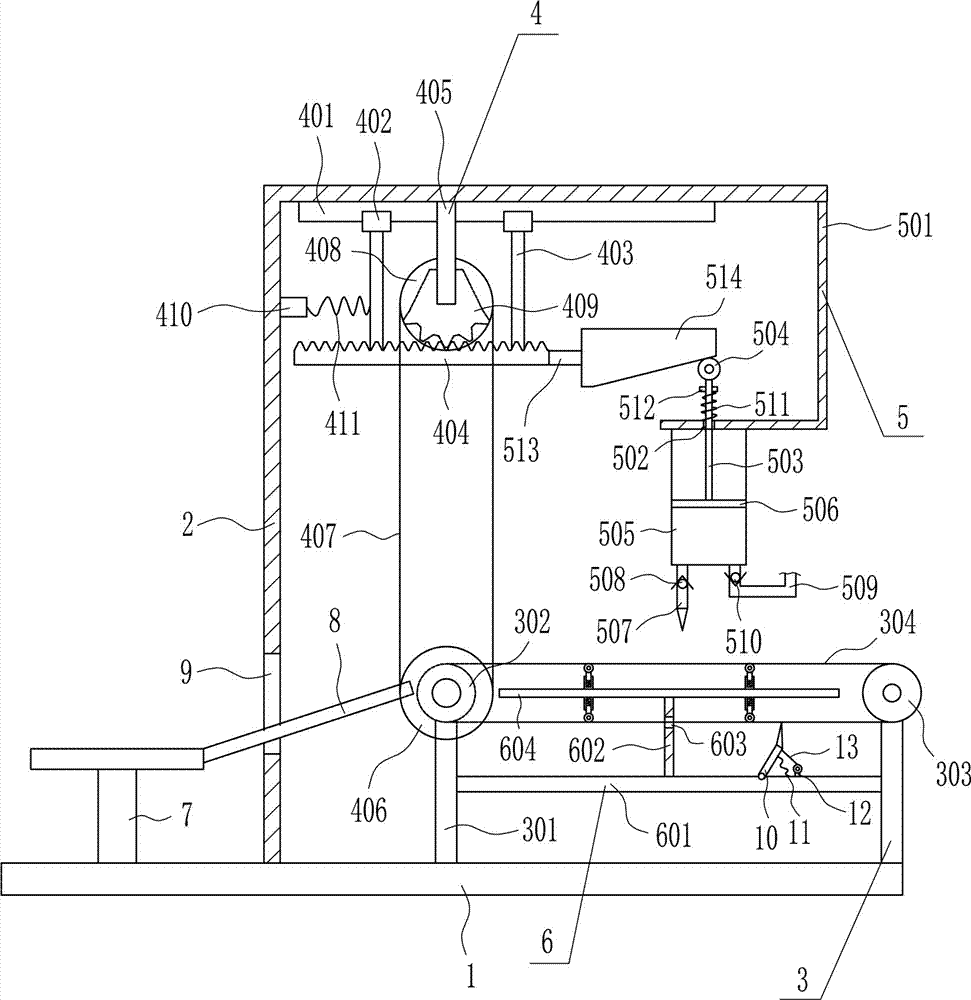

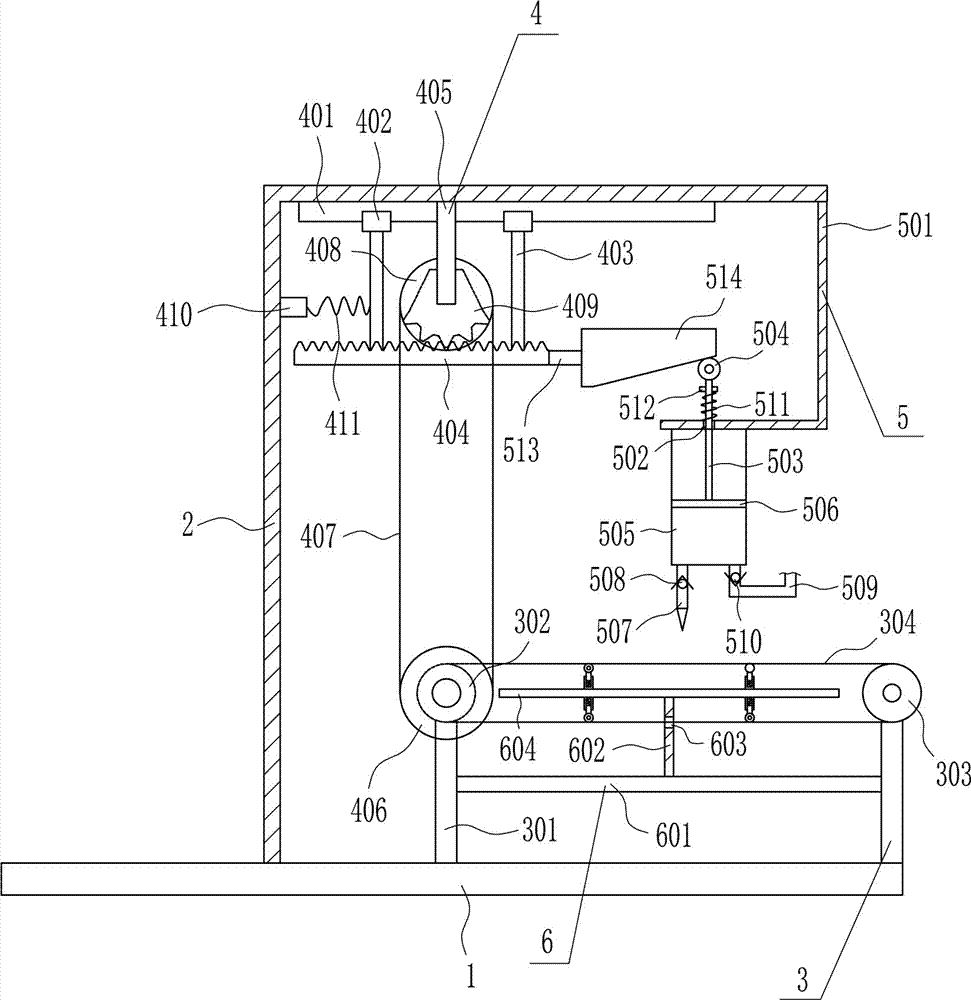

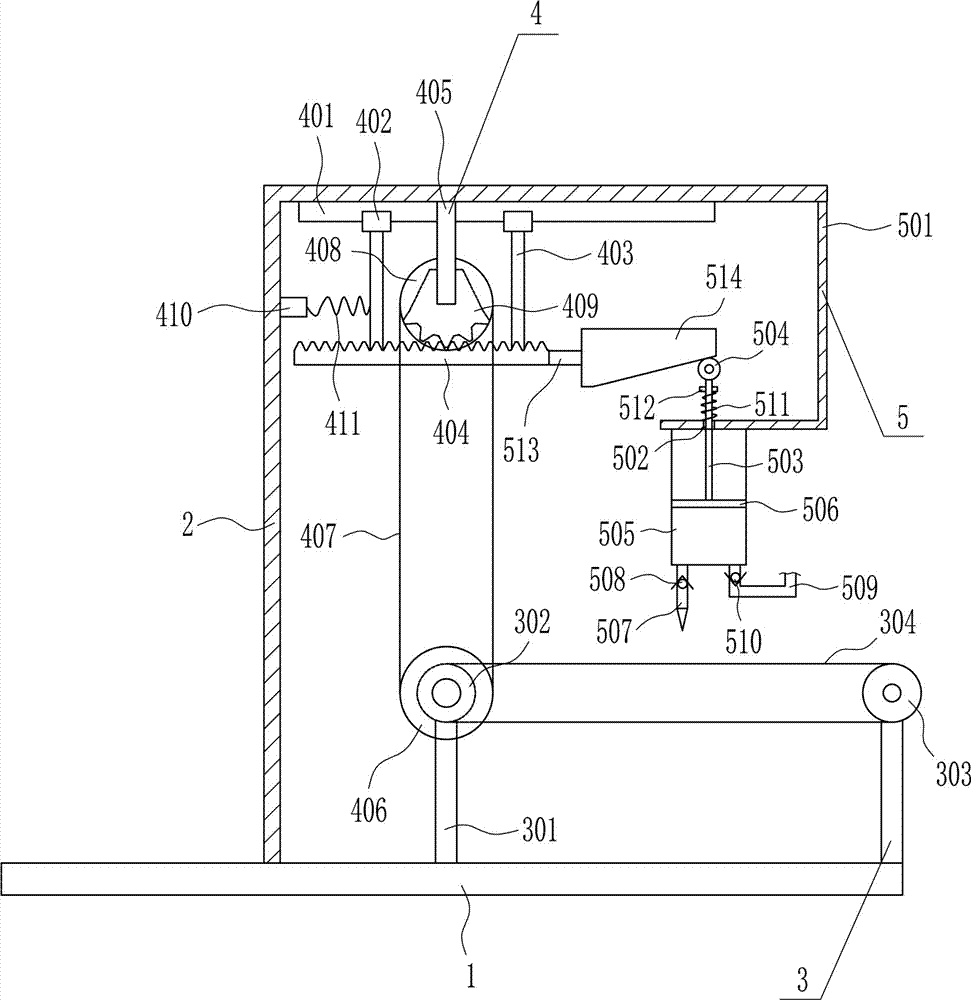

[0030]A kind of gluing equipment for the production of electronic components, such as Figure 1-4 As shown, it includes base plate 1, type 7 plate 2, conveying device 3, driving device 4 and gluing device 5, the left side of the top of base plate 1 is connected with type 7 plate 2, and the right side of the top of base plate 1 is equipped with conveying devices 3 and 7 A driving device 4 is installed on the inner top of the template 2, and the driving device 4 is connected to the conveying device 3. A gluing device 5 is installed on the far right of the inner top of the 7-type board 2, and the gluing device 5 is connected to the driving device 4. The gluing device 5 The gluing part is located directly above the conveying device 3.

Embodiment 2

[0032] A kind of gluing equipment for the production of electronic components, such as Figure 1-4 As shown, it includes base plate 1, type 7 plate 2, conveying device 3, driving device 4 and gluing device 5, the left side of the top of base plate 1 is connected with type 7 plate 2, and the right side of the top of base plate 1 is equipped with conveying devices 3 and 7 A driving device 4 is installed on the inner top of the template 2, and the driving device 4 is connected to the conveying device 3. A gluing device 5 is installed on the far right of the inner top of the 7-type board 2, and the gluing device 5 is connected to the driving device 4. The gluing device 5 The gluing part is located directly above the conveying device 3.

[0033] Conveying device 3 comprises pole 301, electric wheel 302, driven wheel 303 and conveyer belt 304, and base plate 1 top right side is connected with pole 301 symmetrically left and right, pole 301 top on the left side is equipped with elect...

Embodiment 3

[0035] A kind of gluing equipment for the production of electronic components, such as Figure 1-4 As shown, it includes base plate 1, type 7 plate 2, conveying device 3, driving device 4 and gluing device 5, the left side of the top of base plate 1 is connected with type 7 plate 2, and the right side of the top of base plate 1 is equipped with conveying devices 3 and 7 A driving device 4 is installed on the inner top of the template 2, and the driving device 4 is connected to the conveying device 3. A gluing device 5 is installed on the far right of the inner top of the 7-type board 2, and the gluing device 5 is connected to the driving device 4. The gluing device 5 The gluing part is located directly above the conveying device 3.

[0036] Conveying device 3 comprises pole 301, electric wheel 302, driven wheel 303 and conveyer belt 304, and base plate 1 top right side is connected with pole 301 symmetrically left and right, pole 301 top on the left side is equipped with elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com