Cooking method of automatic cooking machine

A cooking machine, automatic technology, applied in cooking utensils, household utensils, food science and other directions, can solve the problems of complicated operation, can not completely solve the damage, the inner wall of the pot can not be stirred and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, eggs are used as the first food material, and tomatoes are used as the second food material to illustrate the beneficial effects and specific implementation steps of the present invention.

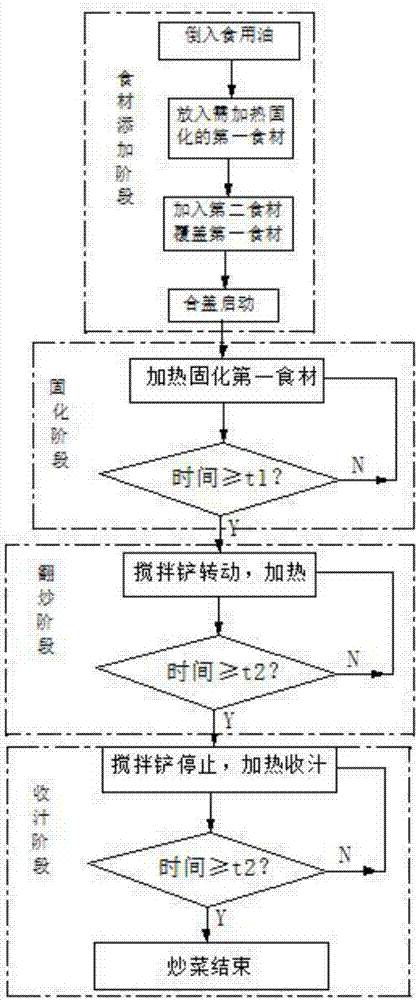

[0032] see figure 1 Shown, a kind of cooking method of automatic cooking machine of the present invention comprises the following steps:

[0033] First, the stage of adding ingredients: first pour cooking oil into the bottom of the wok, then put in the first ingredient that needs to be heated and solidified, and finally add the second ingredient to cover the first ingredient, close the lid to start. In this way, the second ingredient achieves pressure to ensure that the first ingredient adheres to the inner wall of the wok, and the cooking oil provides lubrication, anti-sticking and frying effects, which can quickly form the first ingredient and prevent it from adhering to the inner wall of the pot , and enhance the fragrance of the first ingredient. In this em...

Embodiment 2

[0044] In this embodiment, the specific implementation process and beneficial effects of the present invention are illustrated by taking the first food material as water tofu and the second food material as green vegetables. During the entire cooking process, the difference from the first embodiment lies in the difference in specific cooking parameters such as the difference in curing time and the difference in the rotation speed of the stir-frying stage.

[0045] The details are as follows: First, pour cooking oil into the bottom of the frying pan, put in block or sheet tofu that needs to be heated and solidified, add green vegetables to cover the tofu, close the lid and start.

[0046] Next, a solidification stage is performed: the heating device heats the wok for t1 to solidify the first food material. The t1 time is not less than 1 minute, and may be 2 minutes specifically.

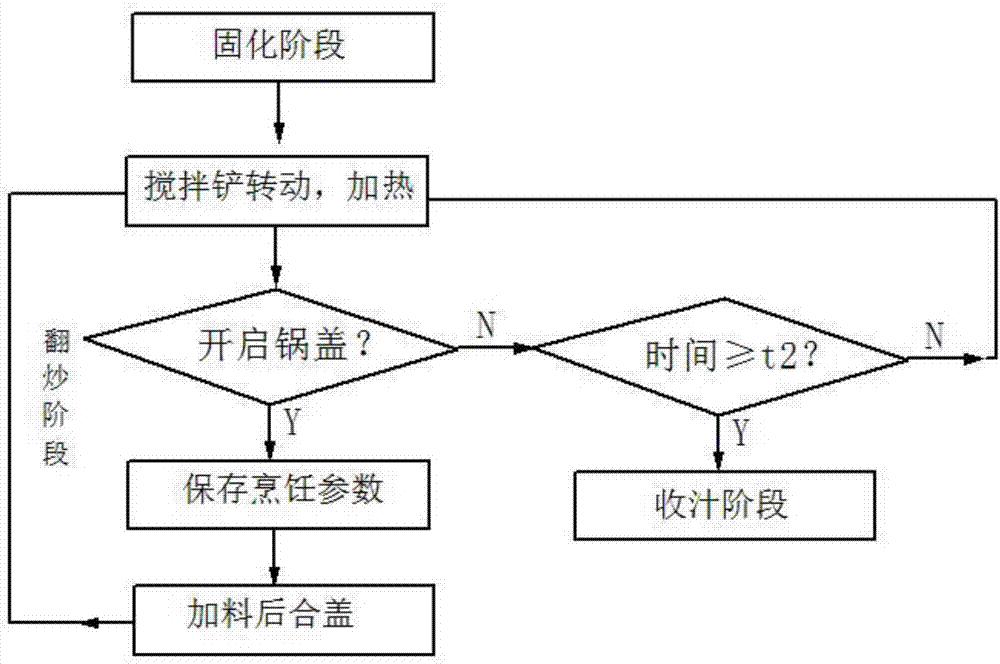

[0047] Then, the stir-frying stage is carried out: the stirring shovel rotates and stir-fries to ...

Embodiment 3

[0051] In this embodiment, the specific execution process and beneficial effects of the present invention are illustrated by taking the first food material as sliced or shredded meat and the second food material as green beans. During the entire cooking process, the difference from the first embodiment lies in the difference in specific cooking parameters such as the difference in curing time and the difference in the rotation speed of the stir-frying stage.

[0052] In this embodiment, the first food material is meat, which is shredded meat or sliced meat. The main purpose of curing is to solidify fat and fat. The meat is delicious.

[0053] In this embodiment, the specific curing time t1 is 2 minutes.

[0054] Moreover, after the meaty first food material is solidified, it is not easy to break. Therefore, in the stir-frying stage, its rotation speed can be set slightly higher to form the effect of turning over the stir-fry, specifically, it can be 30-65 rotations / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com