Cloth dyeing and drying device

A drying equipment and technology for dyeing cloth, applied in the textile field, can solve the problems of affecting the dyeing effect of dyeing cloth, secondary impregnation of cloth, affecting drying effect, etc., and achieve good drying effect, increase area, and improve drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

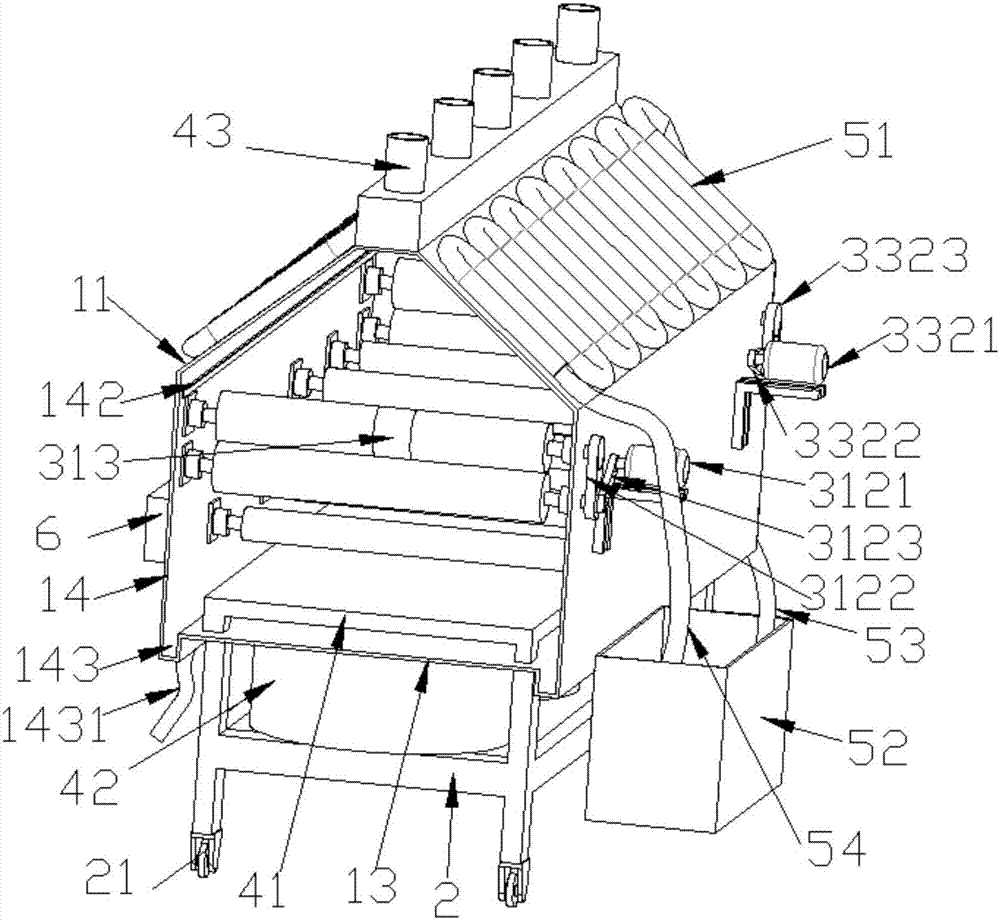

[0044] Such as Figure 1 to Figure 5 As shown, a dyeing cloth drying equipment is characterized in that: it includes dense

[0045] Sealing 1, fixed chassis 2, transmission system 3, drying system 4, condensation system 5, control

[0046] station 6;

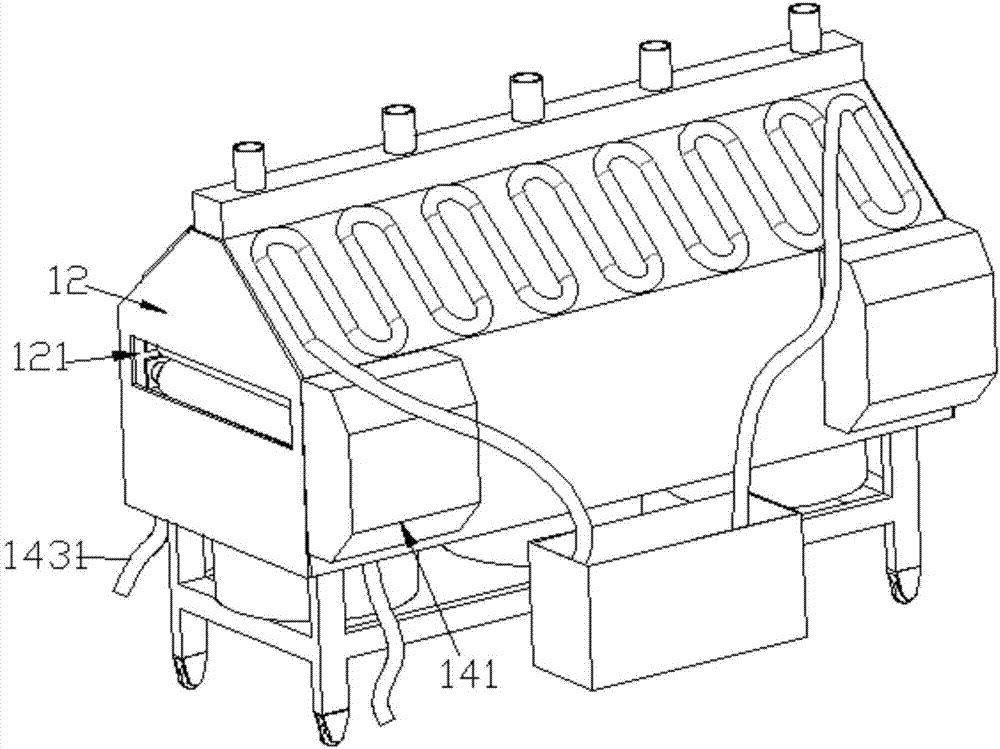

[0047] The sealed box 1 includes a box top 11, a box end 12, a box bottom 13, and box side panels 14;

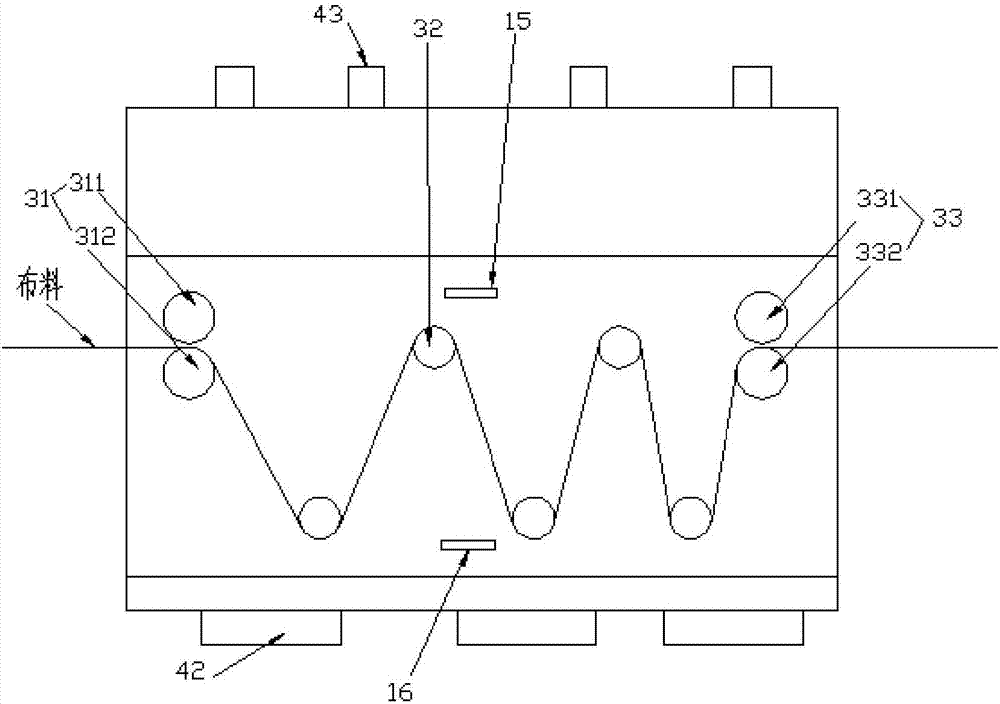

[0048] The transmission system 3 includes a cloth inlet roller 33, a cloth outlet roller 31, and a cloth guide roller 32;

[0049] The cloth inlet roller 33 and the cloth outlet roller 31 are fixed at both ends of the inside of the box side plate 14; The distance between the cloth guide rollers 32 of the cloth rollers 33 is getting smaller and smaller;

[0050] The cloth feeding roller 33 includes an upper cloth feeding roller 331 and a lower cloth feeding roller 332, the lower cloth feeding roller 332 is driven by a first motor 3321 through a first belt 3322, and the lower cloth feeding roller 332 passes through The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com