Packaging system for snus

A packaging system and snus technology, applied in packaging, packaging food, packaging protection, etc., can solve the problems of affecting packaging efficiency, no buffer device, low degree of automation and low degree of accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

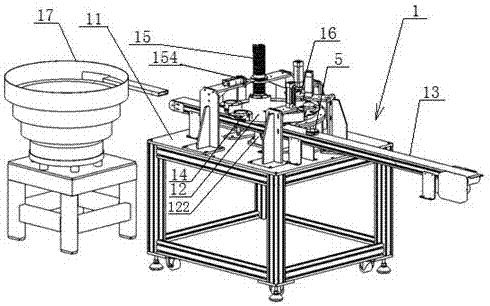

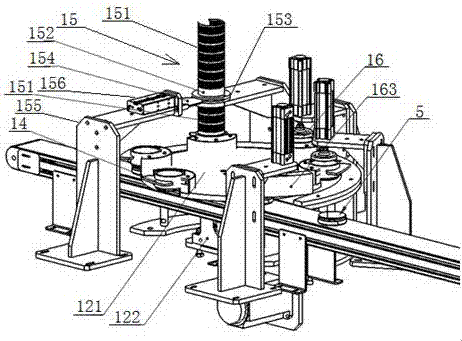

[0072] Such as Figure 1-14 Shown: the snus packaging system, including a set of box-feeding device 1, cap-closing device 2, and weighing, rejecting and buffering device 3 connected in sequence,

[0073] The box-entry device 1 includes a box-entry working platform 11, on which a box-input carousel assembly 12 and a first conveyor 13 are arranged on the box-entry working platform 11, and the first conveyor 13 is arranged on the box-entry carousel assembly 12 The bottom of the box; on the box-entry turntable assembly 12, there is a feed ring assembly 14, and the feed ring assembly 14 is connected with the feed mesh cylinder assembly 15 and the discharge lift cylinder assembly 16, in the first The front end of conveyor 12 is connected with feeding device 17;

[0074] Capping device 2 comprises a capping working platform 21, on which a capping turntable 22 is arranged, and a second conveyor 23 is set below the capping rotating disk 22; A lid feeding assembly 24, a lid assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com