A Parallel Artificial Muscle with Variable Stiffness

A technology of artificial muscle and variable stiffness, applied in manufacturing tools, program-controlled manipulators, manipulators, etc., can solve the problems of unadjustable stiffness and small output force of artificial muscles, and achieve the effect of real-time adjustable stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

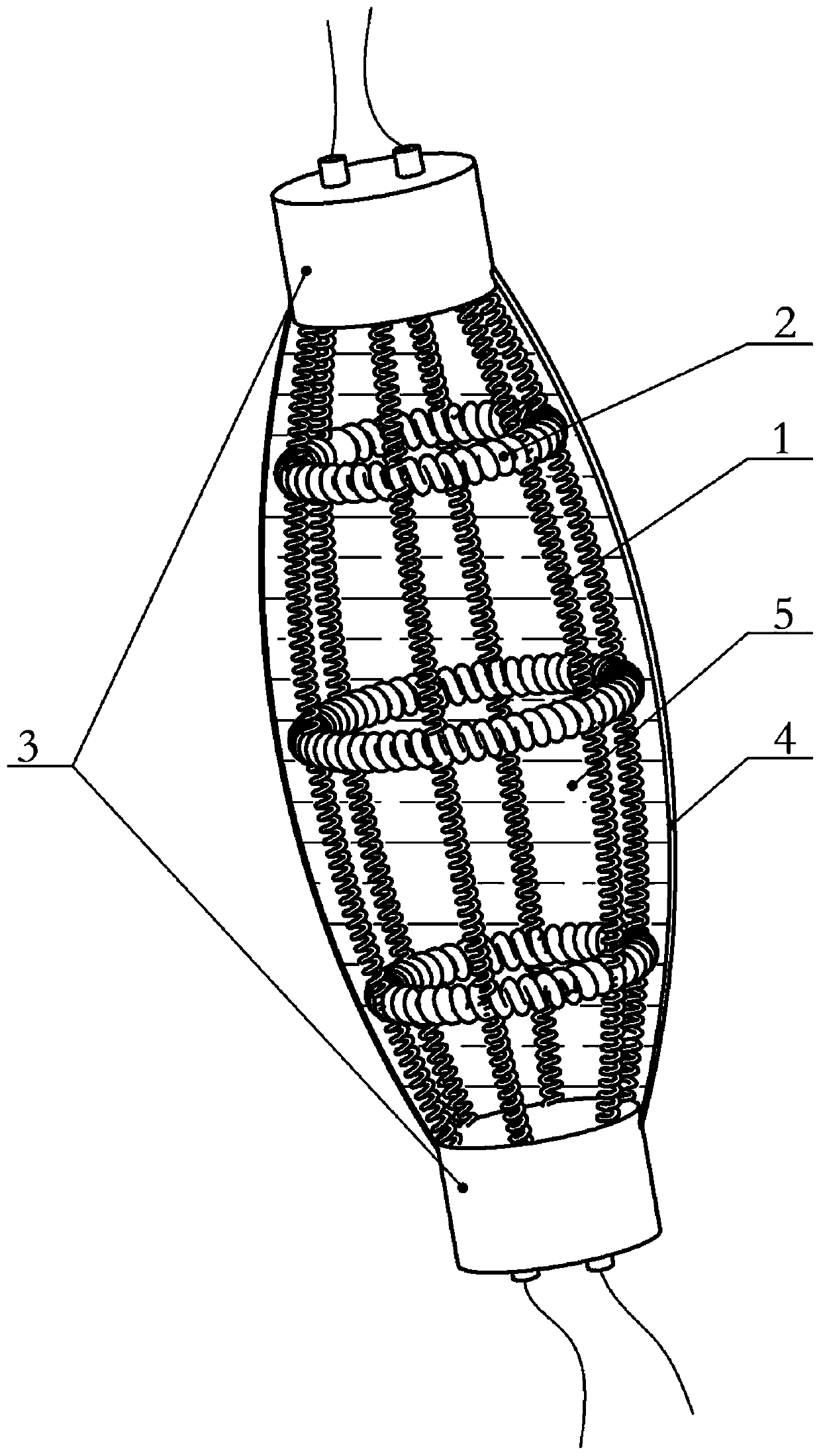

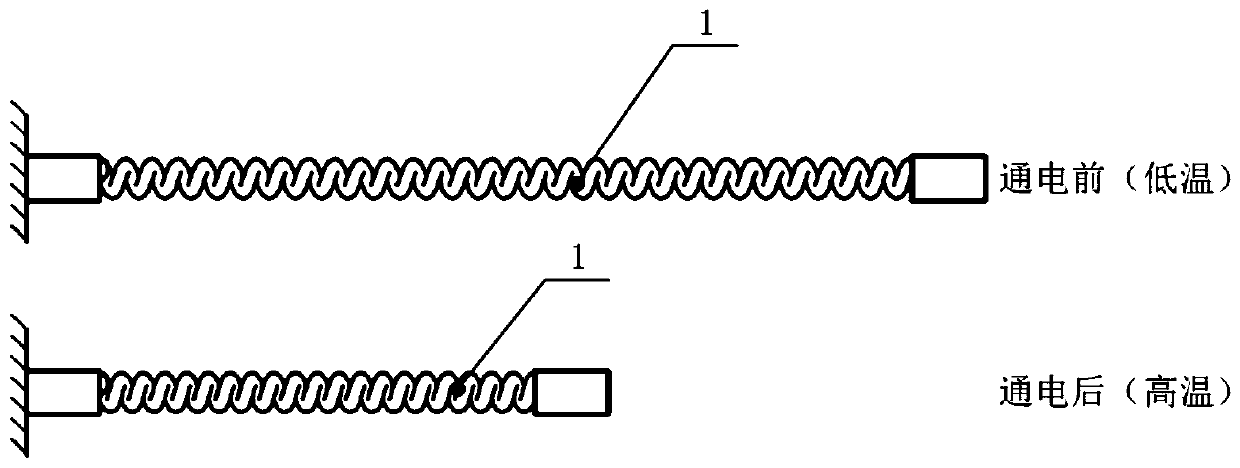

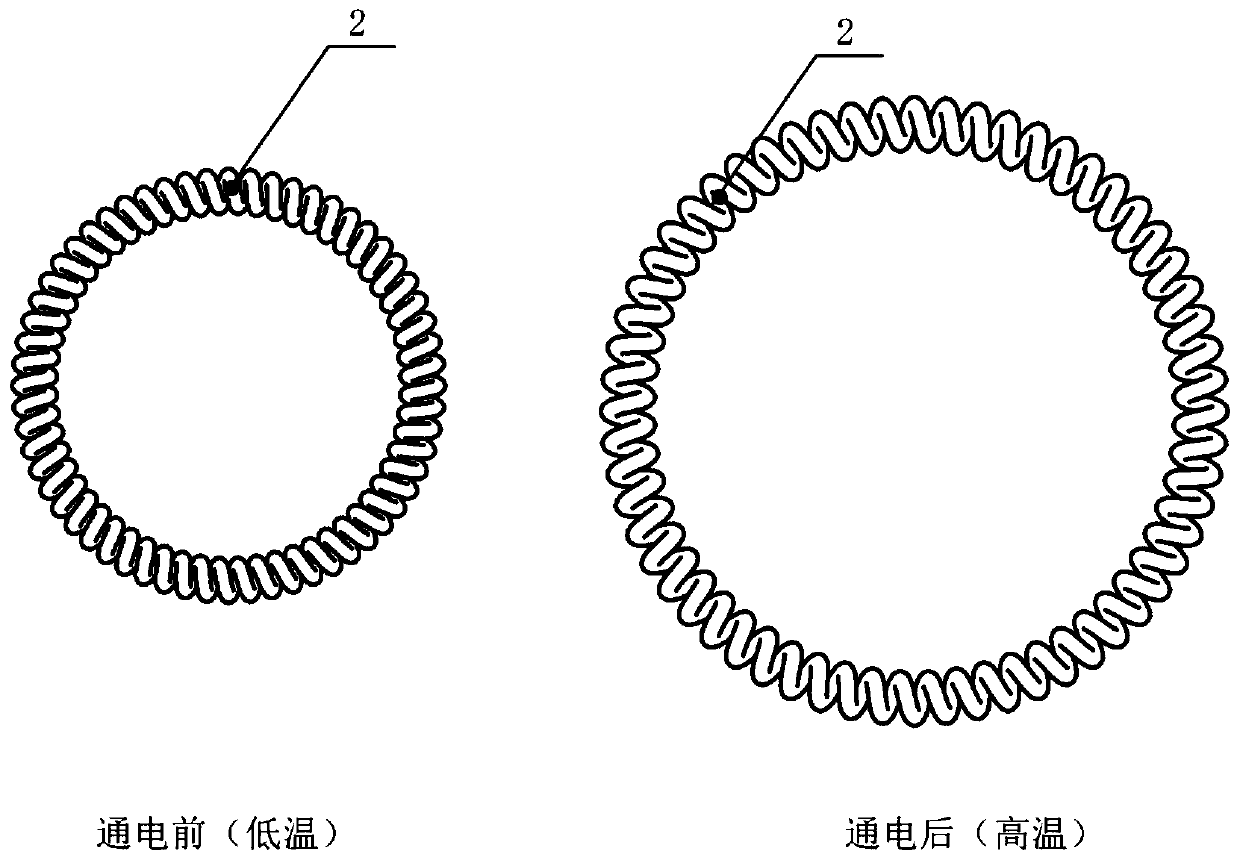

[0022] combine Figure 1 to Figure 6 To illustrate this embodiment, the variable stiffness parallel artificial muscle proposed in this embodiment includes a variable stiffness parallel artificial muscle comprising 6 contractile fibers 1 and 3 elongation fibers 2, including 6 contraction fibers 1 and 3 elongation fibers 2. Two exciters 3, flexible membrane 4 and magnetorheological fluid 5.

[0023] The two ends of the six shrinkable fibers 1 are arranged in a circular pattern on the connection end surface of the corresponding fixed exciter 3; the three elongated fibers 2 are surrounded by the six shrinkable fibers 1 in a direction perpendicular to the shrinkable fibers 1, And form a frame with 6 contraction fibers 1; the flexible film 4 covers the outside of the frame, and wraps the frame in the flexible film 4; the flexible film 4 is airtightly connected with two exciters 3 to form an airtight container cavity; the magnetorheological fluid 5 is placed in a closed cavity.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com