Gas welding protection device

A protective device and gas technology, applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as blocked pipelines, pollute the environment, destroy ecological balance, etc., and achieve the effect of increasing the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

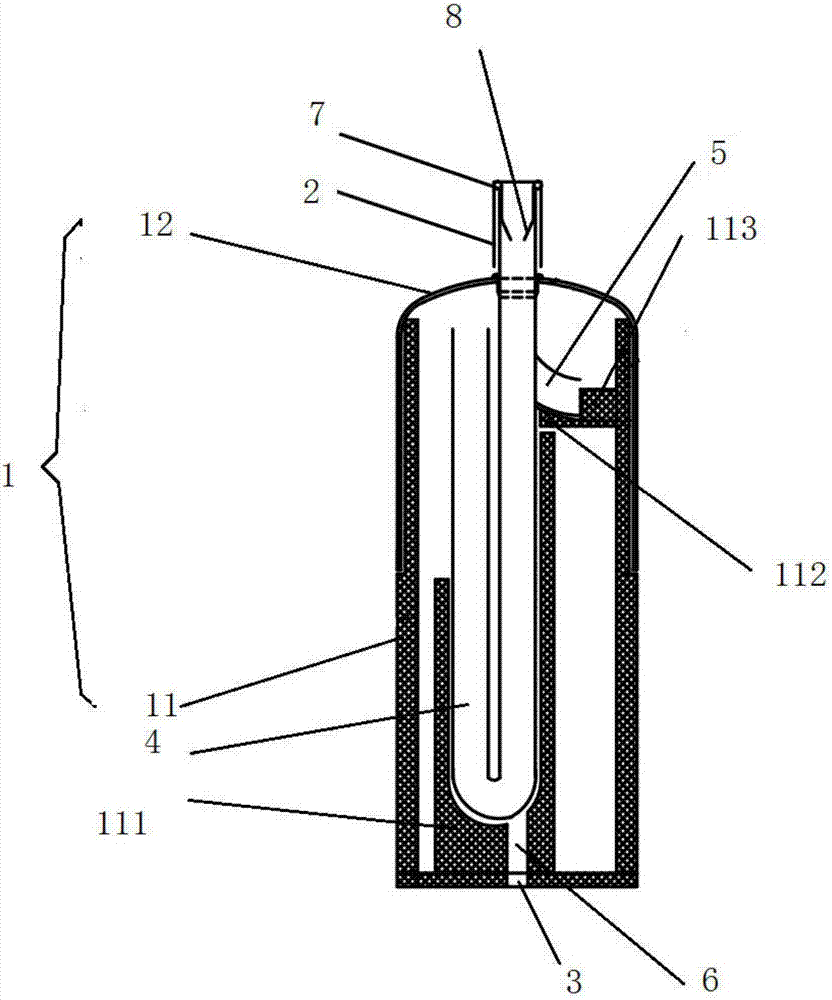

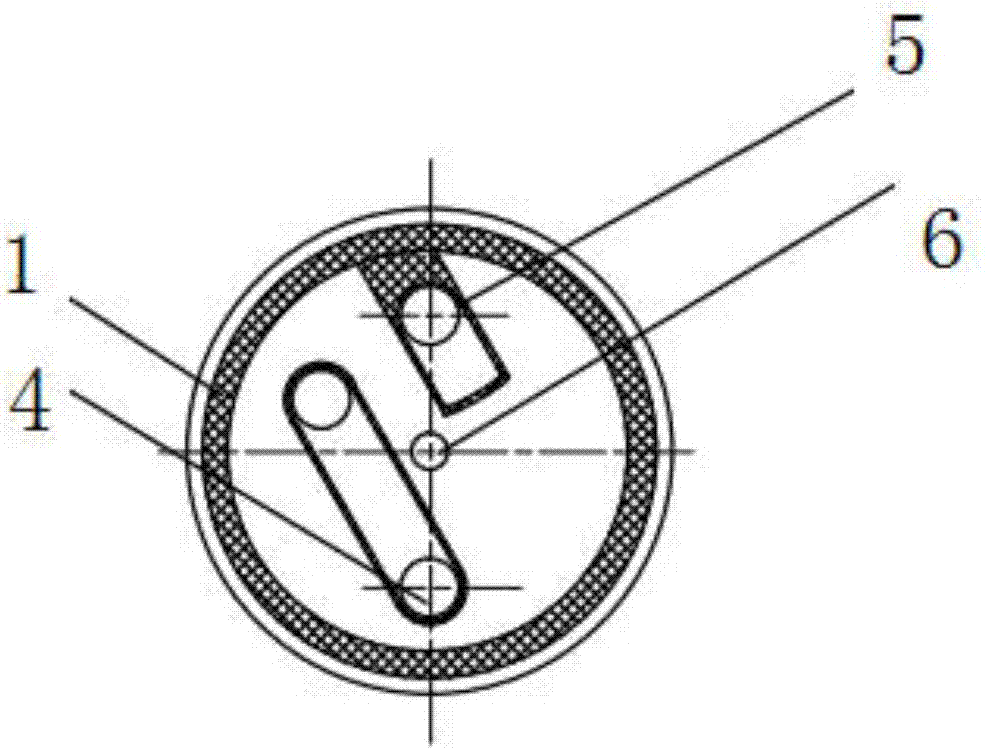

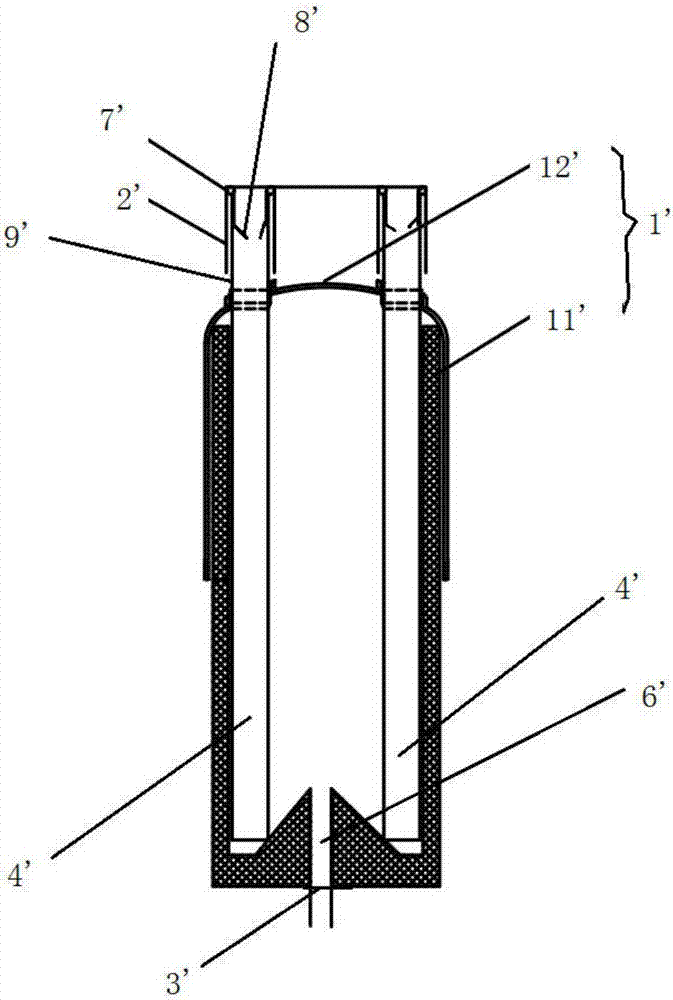

[0026] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0027] The invention is suitable for the gas welding protection occasions of metal fittings requiring gas protection welding in the refrigeration industry.

[0028] According to the embodiment of the present invention, the present invention uses shielding gas to protect the welding parts of the flame-welded parts, so that the flame-welded parts do not produce oxides so that pickling is no longer used, effectively reducing the cost of the enterprise. Cost and reduction of hazardous chemical hazards enable enterprises to enhance practicability without increasing costs, affecting normal use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com