Industrial solid waste treatment device and homogenization method thereof

A solid waste slag and processing device technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problems of high labor intensity, harsh on-site environment, and large floor area, and achieve high production efficiency , reduce personnel, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

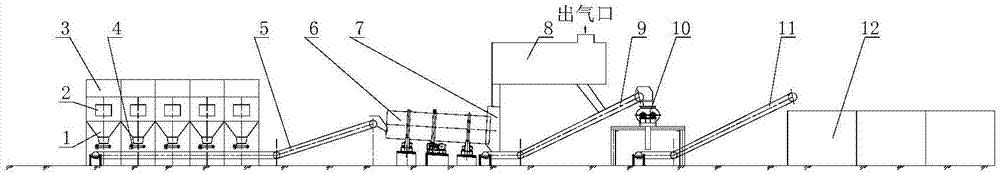

[0029] Such as figure 1 As shown, a treatment device for industrial solid waste of the present invention includes a hopper 1, a first dust collector 3, a first conveyor 5, a drum mixer 6, a second dust collector 8, a second conveyor 9, Mixer 10 and the third conveyor 11; Wherein,

[0030] The receiving hopper 1 includes a plurality of receiving hopper units, which are independent of each other. The upper part of the feeding port of the receiving hopper is provided with a first dust collector 3, and an electronic belt scale is installed below the outlet of each receiving hopper unit. 4;

[0031] The mixing dehumidification unit is used for mixing and dehumidifying industrial solid waste, including: a drum mixer 6 and a second dust collector 8, wherein the outlet end of the drum mixer 6 is equipped with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com